Device and method for measuring digital image of sample surface deformation based on sub-pixel angular point recognition

A digital image, surface deformation technology, applied in the direction of measuring device, using optical device, using stable tension/pressure test material strength, etc., can solve the problem of difficult sample research, low measurement accuracy, and lack of strain field and other issues to achieve the effect of facilitating re-analysis and research, increasing data sampling frequency, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

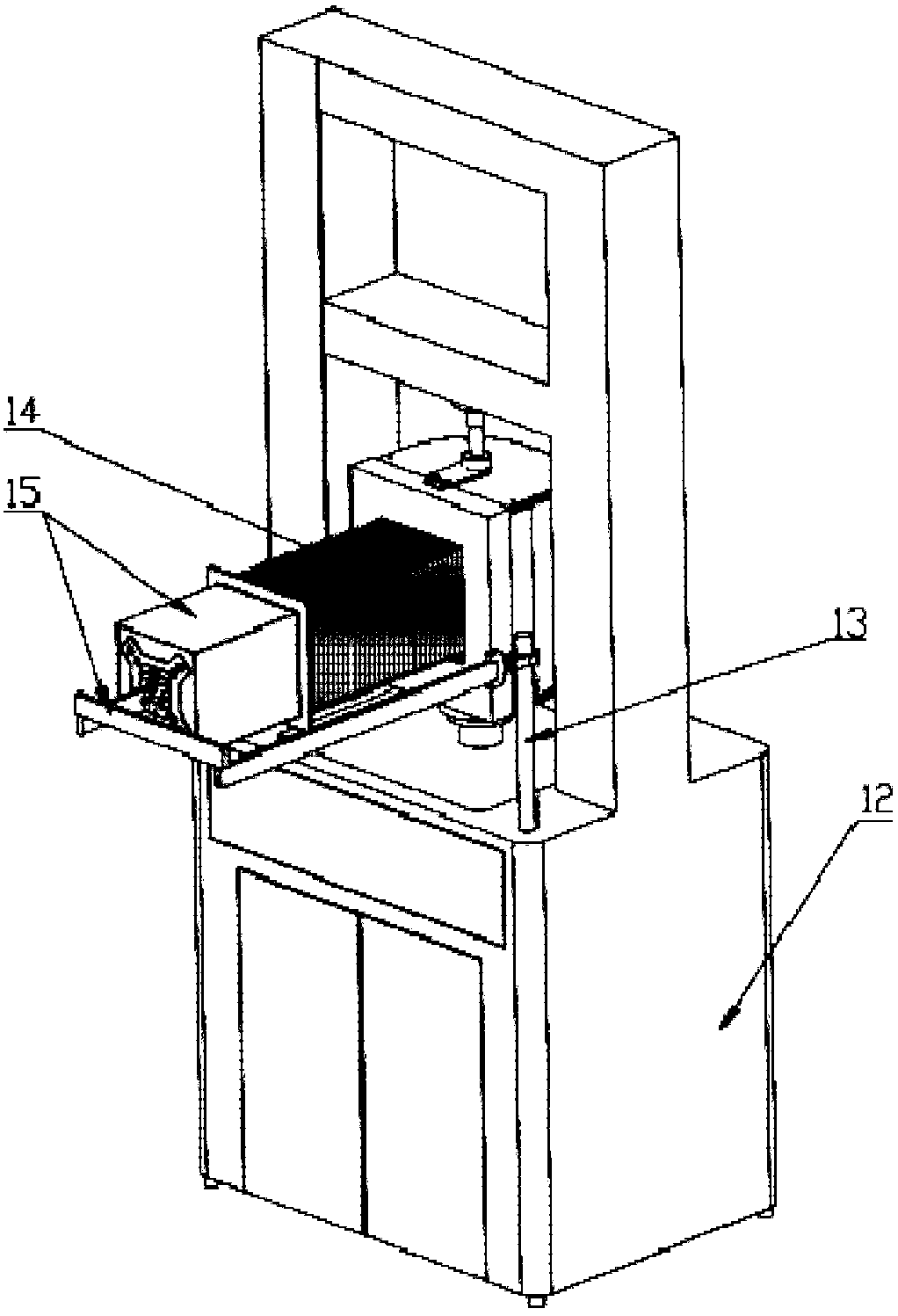

[0031] A digital image measurement device for sample surface deformation based on sub-pixel corner point recognition, including a map measurement pressure chamber, a CMOS industrial camera, a camera bracket 15, a flexible light shield 14, and a computer.

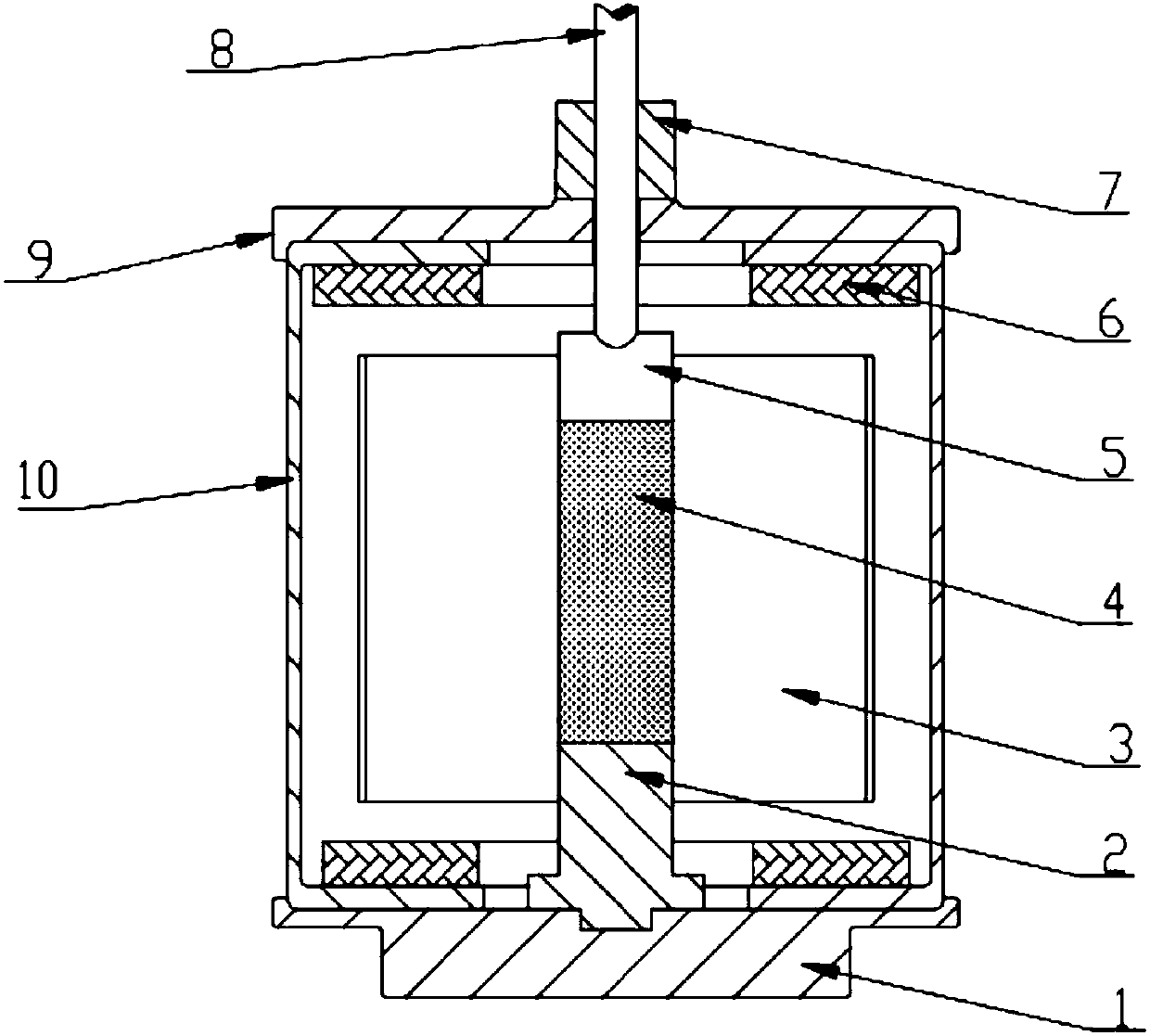

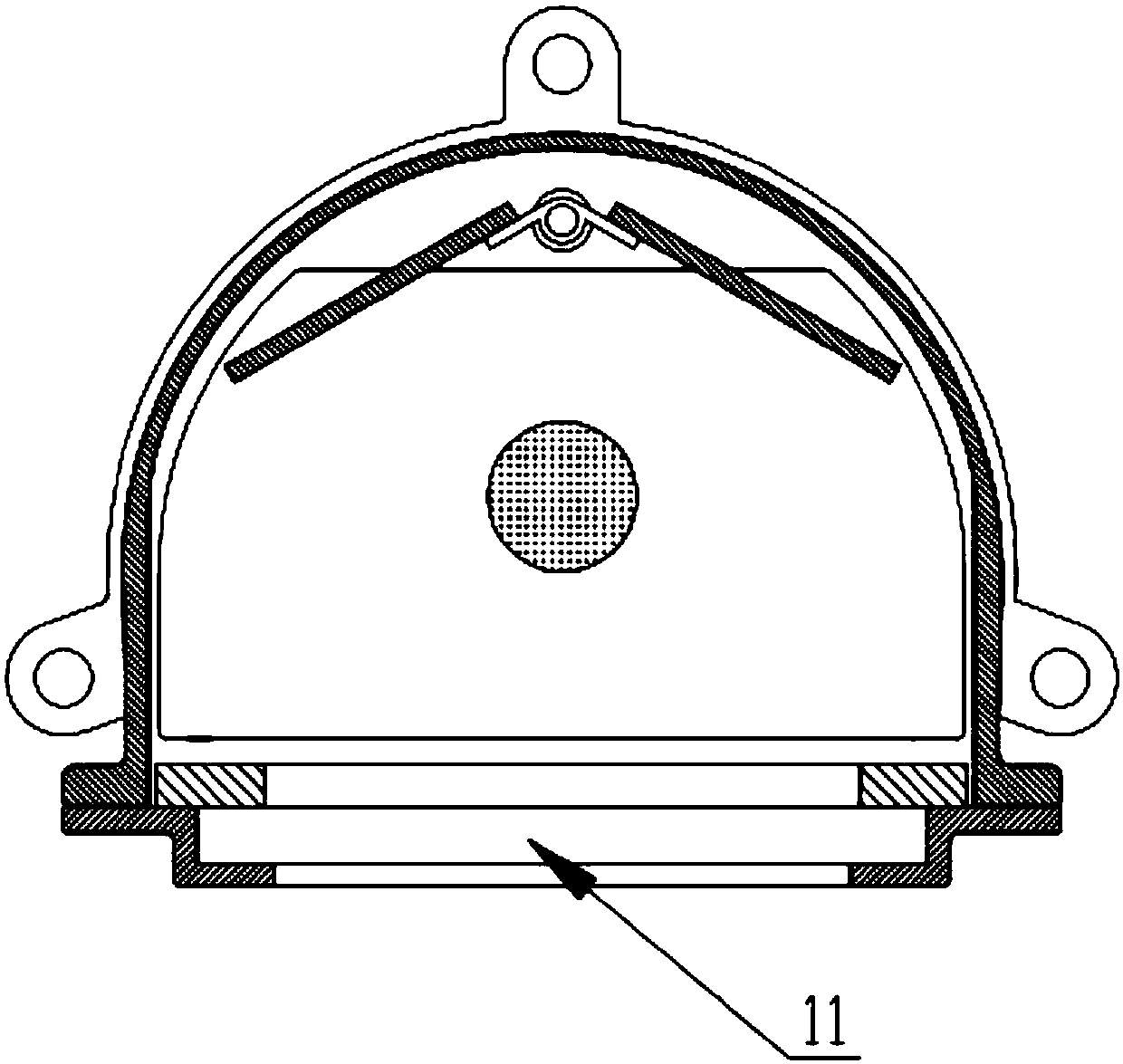

[0032] The planar tempered glass 11 on the front panel of the graph test pressure chamber is fixedly connected with the graph test pressure chamber 10 to form a sealed graph test pressure chamber cavity. The two sides of the graph test pressure chamber are fixed inside the cavity of the plane mirror 3 with a mutual angle of 120°, which is located on the cylinder. Directly behind sample 4. The lower end of the cylindrical sample 4 is fixedly installed on the sample base 2, and the sample base 2 is installed on the base 1 of the pressure chamber of the graph through threads, and a sample loading cap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com