A 3D printing filling path generation method based on association tree

A technology of 3D printing and path generation, applied in instrumentation, design optimization/simulation, calculation, etc., can solve problems such as frequent switching of nozzles, reducing molding efficiency, increasing filling time, etc., to improve filling quality, improve molding efficiency, and versatility Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, and the following embodiments do not constitute a limitation to the present invention.

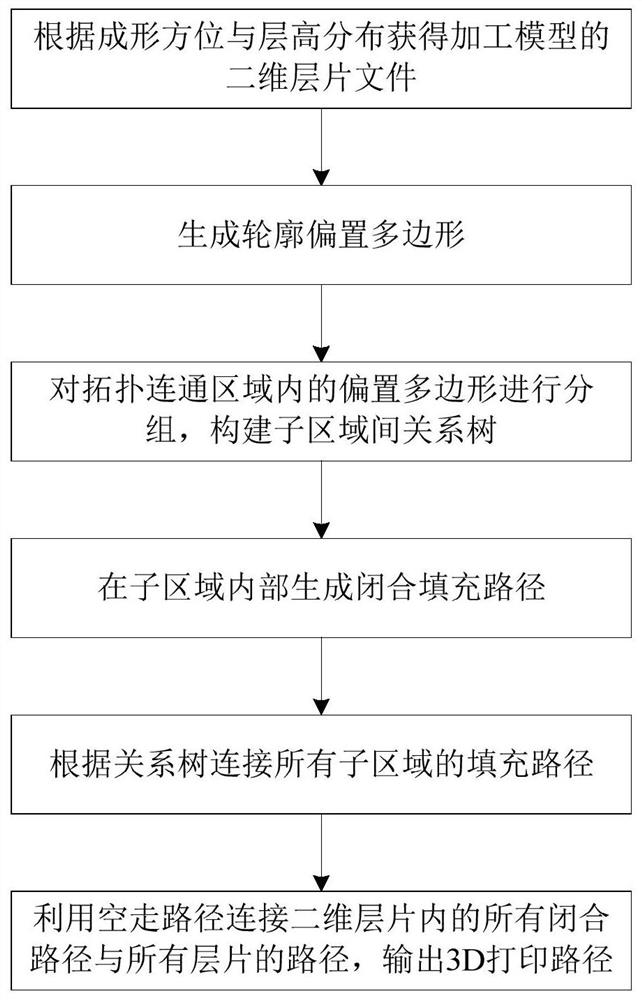

[0051] figure 1 Shown is a flow chart of the general internal filling path generation method of the 3D printing technology of the present invention. to attach figure 2 Take the part section in figure 2 parts shown.

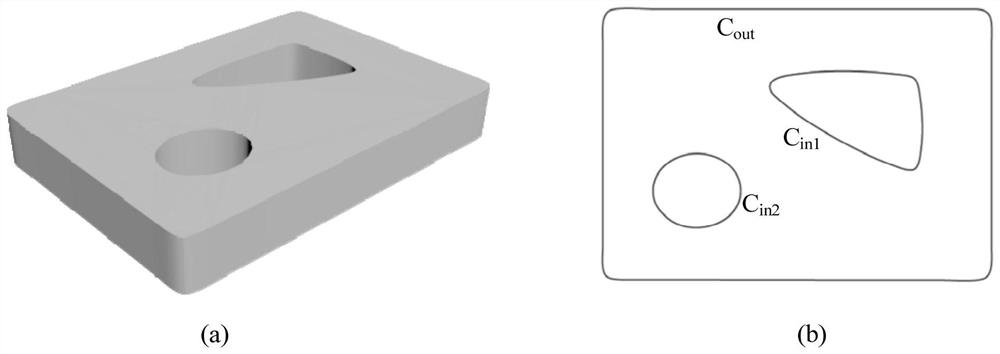

[0052] Step 1. Determine the forming orientation of the parts to be processed according to the requirements of precision and formability, such as figure 2 As shown in (a), the layer thickness is uniformly set to 0.2mm, and the geometric contour information of each layer is obtained by using the slicing software. figure 2 (b) is one of the cross-sectional profiles, including an outer profile C out and two inner contours C in1 and C in2 ;

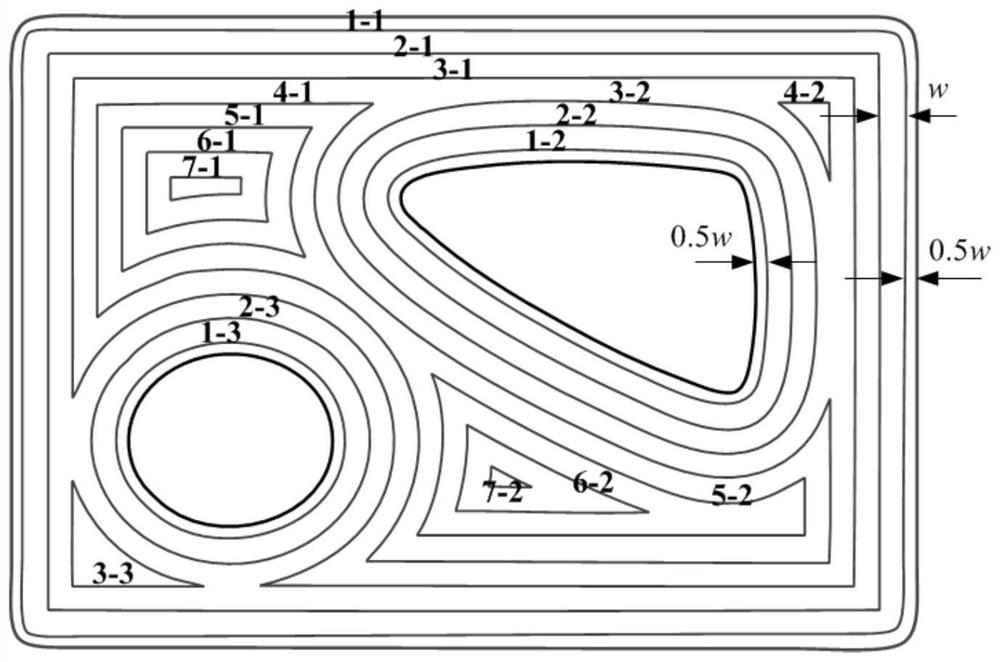

[0053] Step 2. Set the path spacing w as 0.5mm, iteratively offset the outer contour of the ply i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com