High-efficient low-wearing coating dispersing machine

A low-wear, dispersing machine technology, applied in the direction of mixers, mixer accessories, mixers with rotating containers, etc., can solve problems such as adjustment, poor mixing efficiency, and limited use range, so as to reduce loss, improve dispersion effect, and improve The effect of scope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

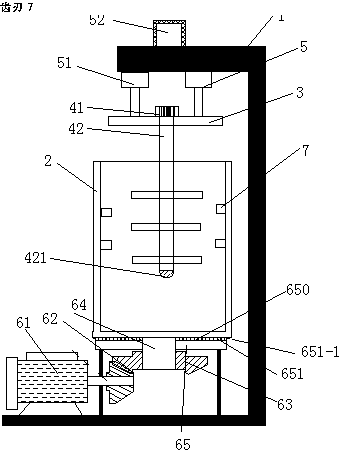

[0017] Such as figure 1 As shown, a high-efficiency low-wear paint dispersing machine includes a support 1, a dispersion bucket 2, a top plate 3, and a stirring mechanism fixed on the top plate 3. The stirring mechanism includes a first motor 41 and a stirring shaft 42, and the top plate 3 is also fixed. The lifting mechanism 5, the lifting mechanism 5 includes a hydraulic cylinder 51 fixed on the top plate 3 and a controller 52 for controlling the movement of the hydraulic cylinder 51, the hydraulic cylinder 51 and the controller 52 are fixed on the support 1; the end of the stirring shaft 42 is provided with A pressure sensor 421, the pressure sensor 421 is electrically connected with the controller 52;

[0018] The bottom of dispersing barrel 2 is provided with rotating mechanism 6, and rotating mechanism 6 comprises second motor 61, the driving bevel gear 62 that is connected with second motor 61, the passive bevel gear 63 that meshes with driving bevel gear 62, is driven ...

Embodiment 2

[0020] Based on the high-efficiency and low-wear paint dispersing machine in Embodiment 1, it is further optimized. At least three hydraulic cylinders 51 are arranged on the support 1 , and the hydraulic cylinders 51 are evenly distributed on the circumference of the support 1 .

Embodiment 3

[0022] Based on the high-efficiency and low-wear paint dispersing machine in Example 1, it is further optimized, and the stirring shaft 42 is evenly coated with a layer of wear-resistant coating with a thickness of 1-3mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com