Glue dispensing device with ultrasonic vibration and glue dispensing method performed by using same

A technology of dispensing device and ultrasonic vibration, which is applied to devices and coatings that apply liquid to the surface, can solve problems such as the outstanding heat dissipation problem of adhesive LED chips, improve the bonding and fixing effect, and avoid poor bonding. Robust, thermal resistance reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

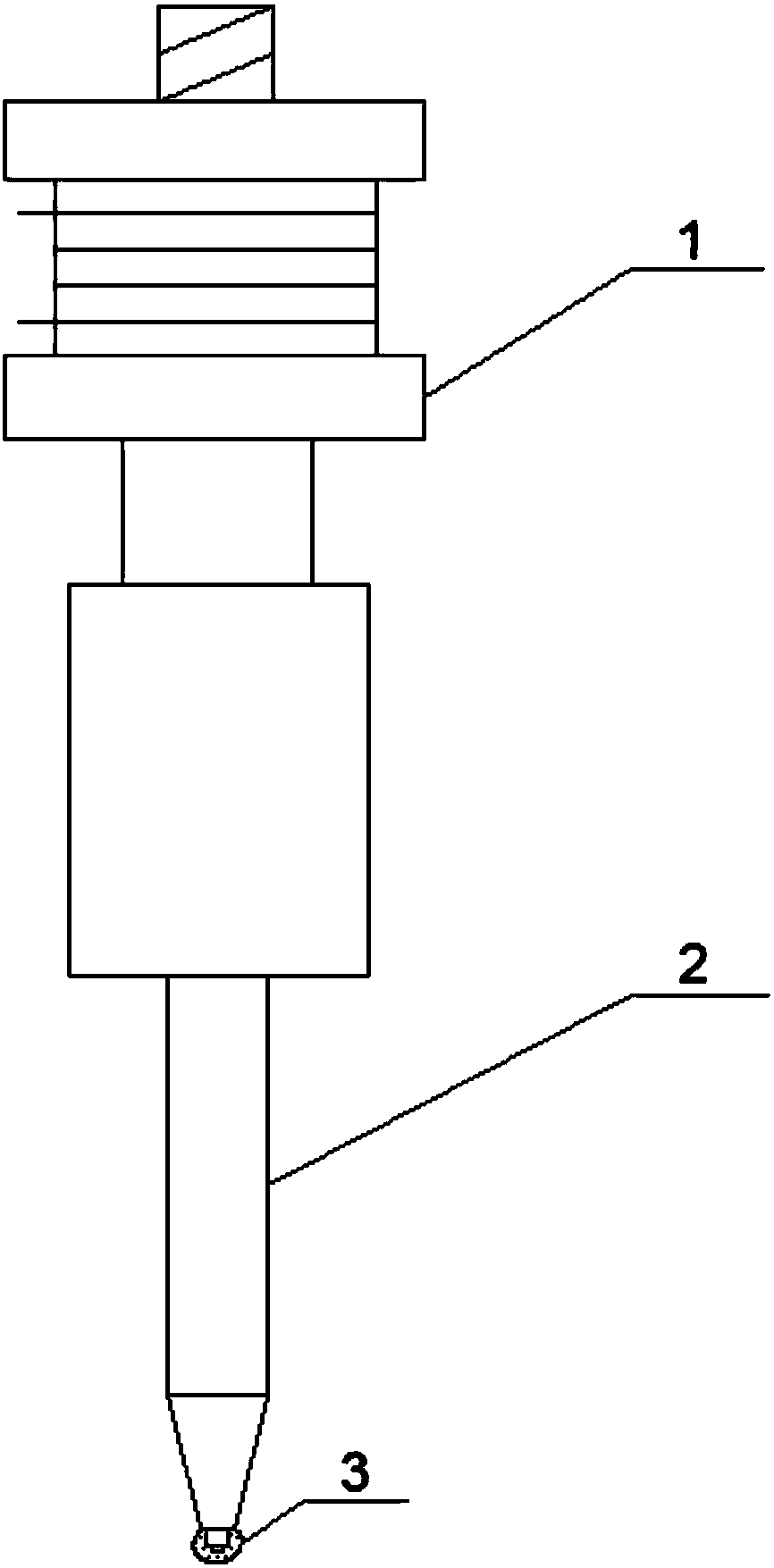

[0016] The invention relates to a dispensing device with ultrasonic vibration and a dispensing method using the dispensing device. The dispensing device includes an ultrasonic transducer 1 and a dispensing head 2 fixed on its ultrasonic output end. The working end of the dispensing head 2 is a diameter Gradually shrinking multi-stage cylindrical steps, cylinders with different diameters are used to form glue drops 33 of different sizes, and the glue dispensing device is used in the process of fixing the LED chip on the bracket. The specific operation process of the glue dispensing method is through specific examples. to explain.

[0017] Specific examples, such as figure 1 As shown, the working end of the dispensing head 2 is a two-stage cylinder with different diameters. After being glued, the glue adheres evenly around it to form a glue drop 3 with a regular shape. A certain adhesive force will not detach when the working end of the dispensing head 2 just leaves the glue su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com