Pile fixing frame structure constructing process

A pile-fixing frame and process technology, applied in the field of pile-fixing structure construction technology, can solve the problems of difficult control of positioning accuracy, difficult precision, deformation, etc., and achieve the effect of high positioning accuracy and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

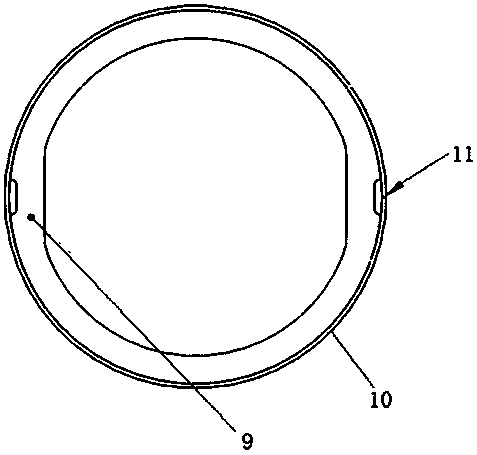

[0045] The construction technology of pile-fixed frame structure of the present invention is concretely realized through the following steps:

[0046] The first step, blanking and cutting: the blanking of all plates is carried out in strict accordance with the drawings and cutting instructions. After blanking, the furnace batch number and material grade number of the plate should be transplanted to each part with multi-stencil, and stamped on the plate away from the plate. Before cutting, the accuracy of the CNC cutting machine should be corrected, the cutting nozzle and the running track should be checked, and the correct cutting parameters should be selected according to the thickness of the plate to ensure the cutting accuracy of the parts and avoid out-of-tolerance pheno...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com