PVC pipe cutting machine

A technology for PVC pipes and cutting machines, which is applied in the direction of tubular objects, metal processing, and other household appliances. It can solve problems such as high labor costs, time-consuming and labor-consuming, and cumbersome structures, and achieve simplified structures, reduced manufacturing costs, and high workability. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

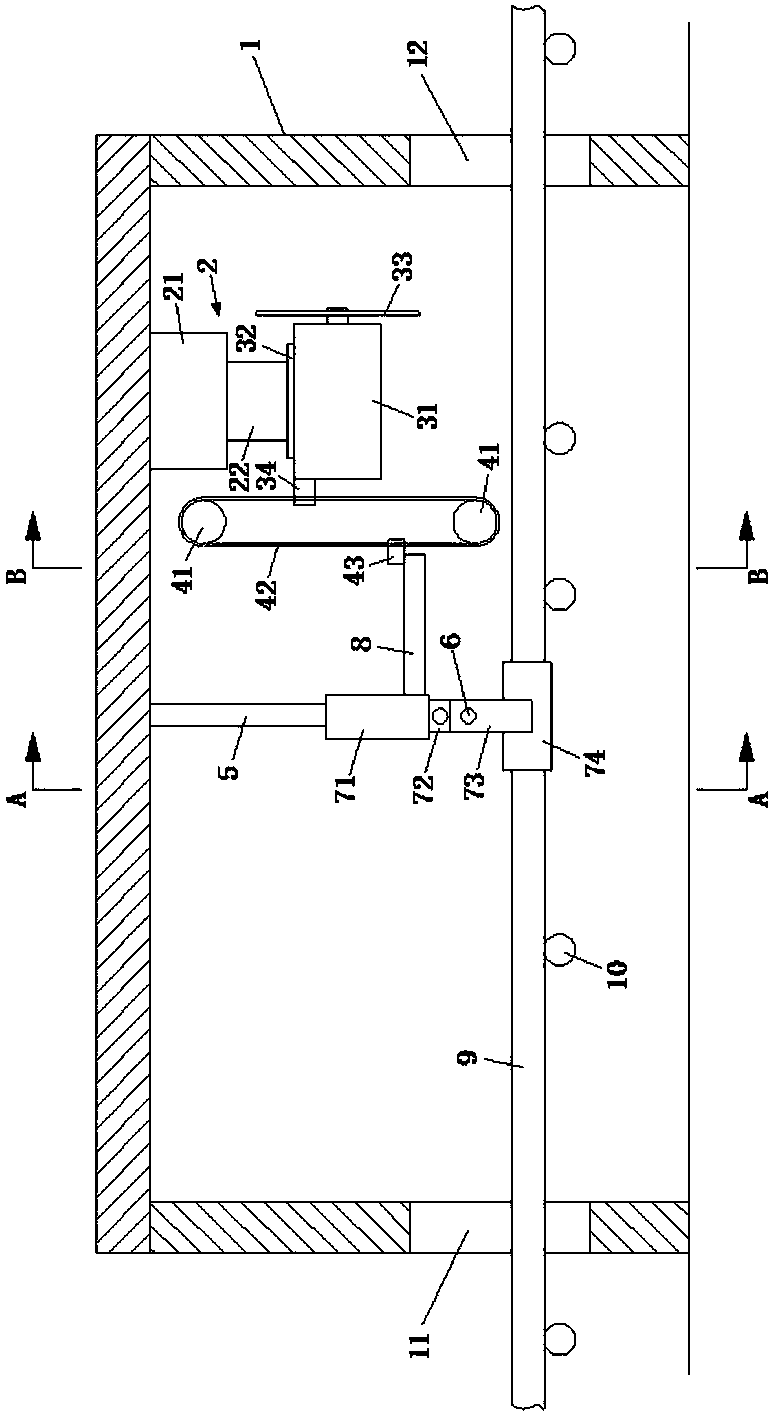

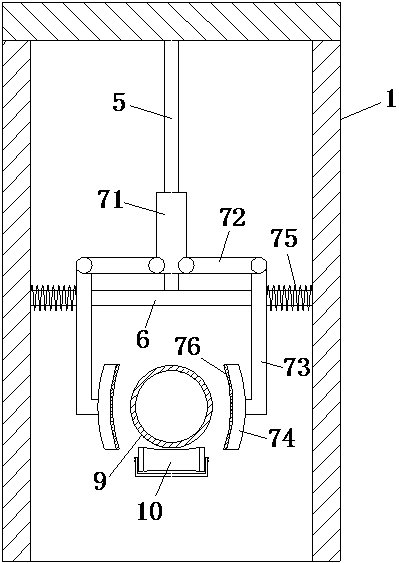

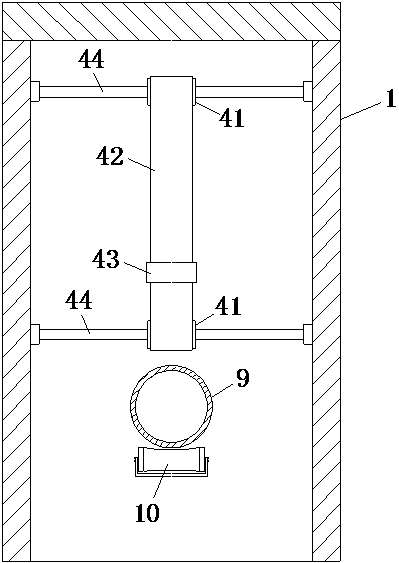

[0025] Such as figure 1 , figure 2 with image 3 As shown, a PVC pipe cutting machine of the present invention includes a box body 1, a hydraulic cylinder 2, a motor 31, a synchronous transmission device, a first support rod 5, a second support rod 6 and a clamping device.

[0026] A material inlet 11 is opened on one side of the box body 1 , and a material outlet 12 is opened on the opposite side.

[0027] The cylinder barrel 21 of the hydraulic cylinder 2 is fixed on the inner top surface of the box body 1 .

[0028] The motor 31 is fixed on the end of the piston rod 22 of the hydraulic cylinder 2 through a connecting piece 32 , and the output shaft of the motor 31 is fixed with a longitudinal saw blade 33 for cutting the PVC pipe 9 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com