Supportless 3D printing method based on five-axis printing platform

A printing platform, 3D printing technology, applied in the direction of 3D object support structure, additive manufacturing, processing data acquisition/processing, etc., can solve the problems of wasteful post-processing process of printing materials, long printing time, damage of printed parts, etc. Process, reduce printing time, improve the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] see Figure 8 , the present embodiment is based on the unsupported 3D printing method of the five-axis printing platform, which is characterized in that: the operation steps are as follows: (1) the model to be printed is converted into an STL model composed of triangular faces (STL files are used in computer graphics applications In the system, a file format used to represent triangular meshes), extract the characteristic edges of the printed model; (2) perform block processing on the characteristic edges of the printed model according to the needs, and determine the main module after block. The model to be printed will leave a section on the main module due to the block cutting, and take the center of gravity of the section as the reference point of this surface; (3) Calculate the angle between the stacking direction of each block manufacturing and the main module manufacturing stacking direction (4) each block is rotated by the X axis according to the included angle c...

Embodiment 2

[0048] This embodiment is basically the same as Embodiment 1, and the special features are as follows:

[0049] In the step (1), the method for extracting the model feature edge is: traverse the triangular faces of the whole model, and calculate the dihedral angles of adjacent triangular faces, thereby judging the structural features:

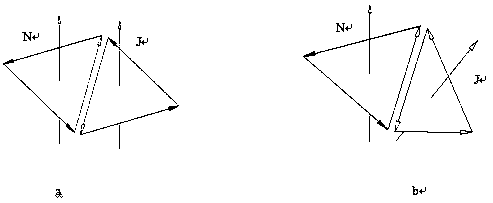

[0050]

[0051] Among them, N is the normal vector of A triangular surface, J is the normal vector of B triangular surface, is the included angle between two adjacent triangular faces, set when When it is greater than 10°, the intersecting edge of two patches is considered as a feature edge.

[0052] In described step (2), the method to model block is:

[0053] (2-1) Set the part that can be printed without any support, that is, the model that is not cut from the 3D model, as the main module;

[0054] (2-2) Calculate the center of gravity (a j , b j , c j );

[0055] (2-3) Recognize the feature edge of the divided model according to...

Embodiment 3

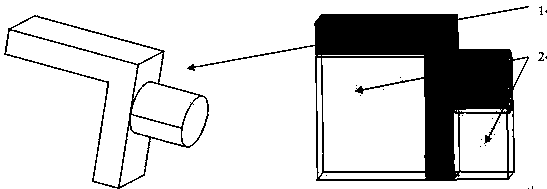

[0067] Such as figure 1 as shown, figure 1 On the left is the model to be printed, figure 1 On the right is the model 1 and its supporting part 2 to be printed. For the traditional FDM process, if no support is added, the cantilever parts on both sides of the model will not be printed.

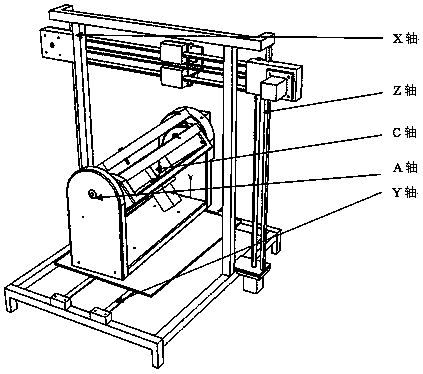

[0068] Such as figure 2 As shown, it is the five-axis printing platform required in this example, with a total of five degrees of freedom, namely X, Y, Z, A, and C. Among them, X, Y, and Z are the existing degrees of freedom of traditional 3D printers, and the two degrees of freedom A and C respectively realize the rotational movement of the receiving platform around the Y and Z axes. The unsupported 3D printing method based on this platform, that is, through the addition of two degrees of freedom, when printing the part of the cantilever structure, by rotating, the part can be printed with the already formed part as the base, so as to achieve unsupported the goal of.

[0069] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com