Air cooled structure permanent magnetic full-electric drive roller

An air-cooled structure, electric drive technology, applied in the direction of electric components, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problems of thermal power loss, reduce transmission efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

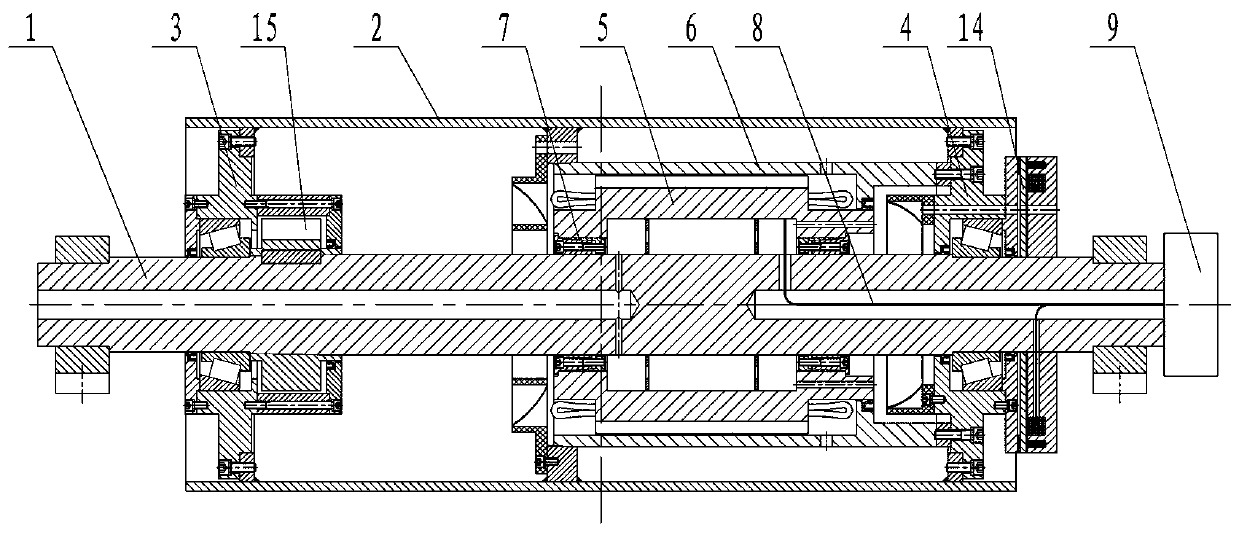

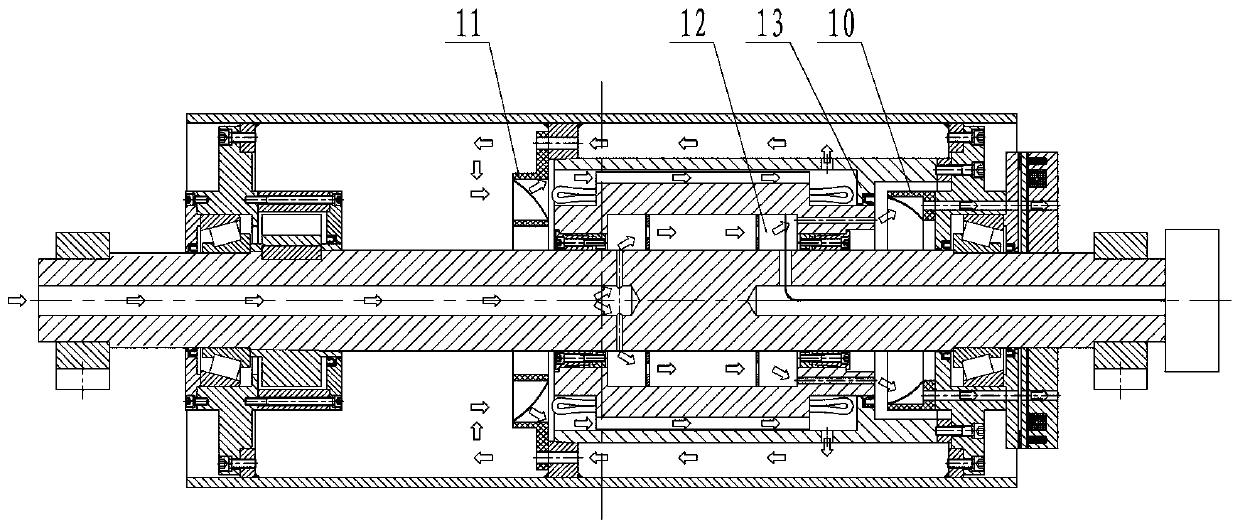

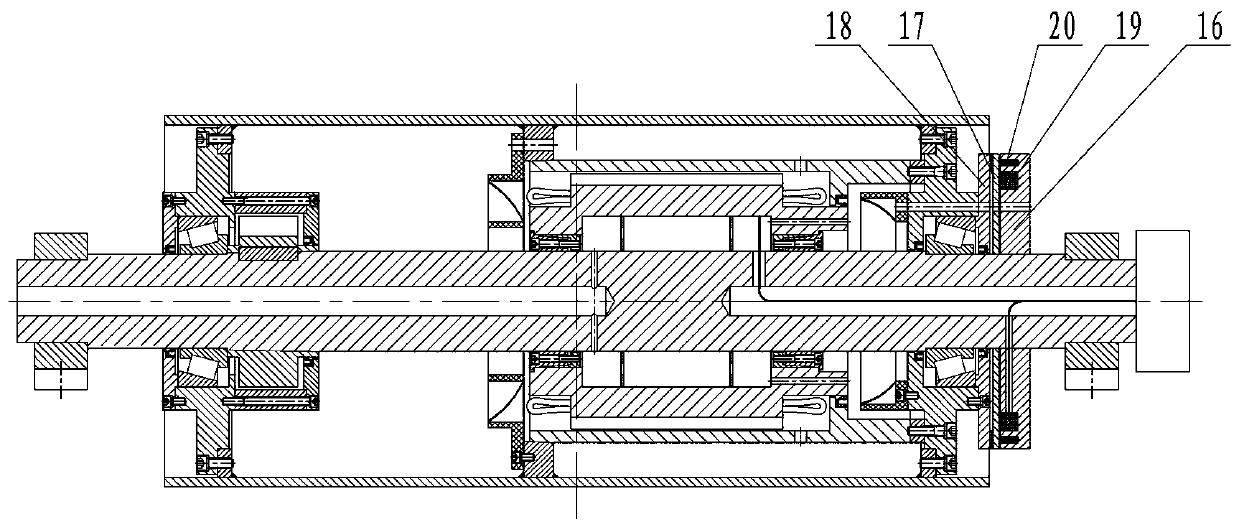

[0020] Such as figure 1 As shown, an air-cooled structure permanent magnet all-electric drive drum is fixedly connected to the stator 5 on the hollow shaft 1 through the expansion sleeve 7, and the winding coil cable 8 on the stator 5 passes through the central hole on the hollow shaft 1 and the hollow shaft 1 The junction box 9 at the end is connected, and the two ends of the hollow shaft 1 are respectively provided with a connection plate I3 and a connection plate II4 through bearings. The permanent magnet rotor 6 is located on the outer circumference of the stator 5 and is connected to the connection plate II4 through bolts; the cylinder body 2 Bolts are used to connect the connection plate I3 and the connection plate II4 respectively; an air-cooling heat dissipation system is provided in the cavity formed between the cylinder body 2, the connection plate I3 and the connection plate II4. The cylinder body 2 of the drum rotates directly by the electromagnetic action of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com