One-dimensional micro-nano particle/epoxy resin composite adhesive film arranged in Z direction and preparation method thereof

A technology of micro-nano particles and epoxy resin, applied in the direction of epoxy resin glue, film/sheet adhesive, film/sheet without carrier, etc., can solve the problem of GIC improvement and achieve good effect and high efficiency , The effect of simple and easy preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

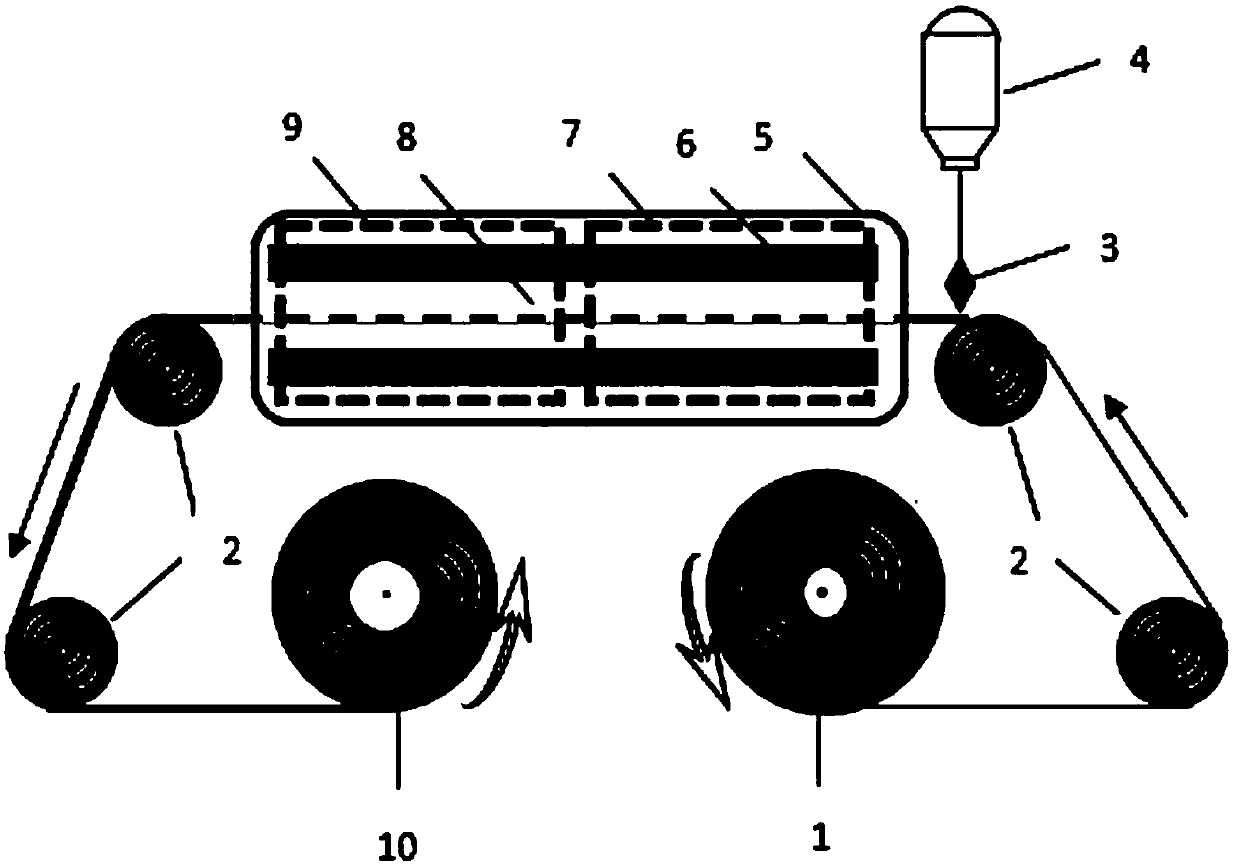

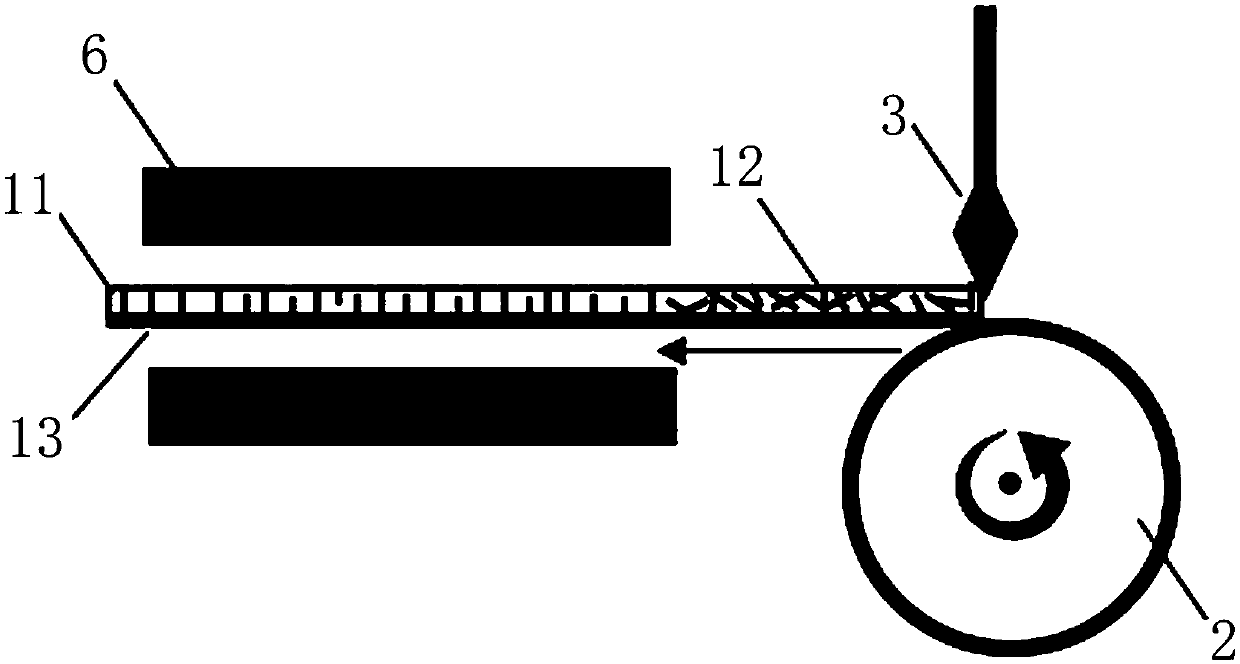

[0027] Load 5g Fe 3 o 4 Calcium carbonate whiskers, 100g of epoxy resin with an epoxy value of 0.35 and 3g of latent curing agent dicyandiamide, mixed evenly by melt blending method, and spread the mixture evenly on the conveyor belt by coating method film.

[0028] Then, the conveyor belt passes through the magnetic field area perpendicular to the conveying direction at a linear speed of 3m / min. When the adhesive film on the conveyor belt passes through the magnetic field at 60°C, the viscosity is about 3 Pa·s, and the magnetic field strength is 0.5T. Within 1min A film in which one-dimensional micro-nano particles are arranged along the Z direction is obtained.

[0029] The oriented adhesive film passes through the solidification area along with the conveyor belt. In this area, the adhesive film is cooled and solidified under the above-mentioned magnetic field and normal temperature, and then changes to a solidified state at normal temperature to obtain a composite adhesiv...

Embodiment 2

[0033] Mix 3g of attapulgite loaded with γ-Fe2O3, 100g of epoxy resin with an epoxy value of 0.4, and 3.5g of latent curing agent dicyandiamide, using acetone as a solvent, using a solution blending method to mix evenly, and use the coating method Spread the mixture evenly into a film on the conveyor belt.

[0034] Then, the conveyor belt passes through the magnetic field area perpendicular to the conveying direction at a linear speed of 4m / min, and the solution concentration control method is used to make the adhesive film on the conveyor belt pass through the magnetic field. The viscosity is about 0.1Pa•s, and the magnetic field strength is 0.8T, 0, A film with one-dimensional micro-nano particles arranged along the Z direction was obtained within 5 minutes.

[0035] The oriented adhesive film passes through the curing zone with the conveyor belt. In this area, the solvent is volatilized under the above-mentioned magnetic field and 120°C, and becomes cured at room temperatur...

Embodiment 3

[0039] 10g of cellulose whiskers loaded with Fe3O4, 100g of epoxy resin with an epoxy value in the range of 0.45, and 4g of latent curing agent dicyandiamide, using acetone as a solvent, mixed uniformly by solution blending, and coated The mixture is evenly spread into a film on the conveyor belt.

[0040] Then, the conveyor belt passes through the magnetic field area perpendicular to the conveying direction at a linear speed of 5m / min, and the solution concentration control method is used to make the adhesive film on the conveyor belt pass through the magnetic field. The viscosity is about 1 Pa·s, and the magnetic field strength is 0.2. A film in which micro-nano particles are arranged along the Z direction.

[0041]The oriented adhesive film passes through the curing zone with the conveyor belt. In this area, the solvent is volatilized under the above-mentioned magnetic field and 100°C, and becomes cured at room temperature to obtain a composite adhesive film with a stable a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap