Manufacture method of anti-counterfeiting brand woven tape

A production method and trademark technology, applied in the direction of fabrics, textiles, textiles and papermaking, etc., can solve the problems of uneven anti-counterfeiting materials, affecting the appearance of yarn products, and loose combination of yarn and anti-counterfeiting materials, so as to improve the anti-counterfeiting effect, Good anti-counterfeiting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

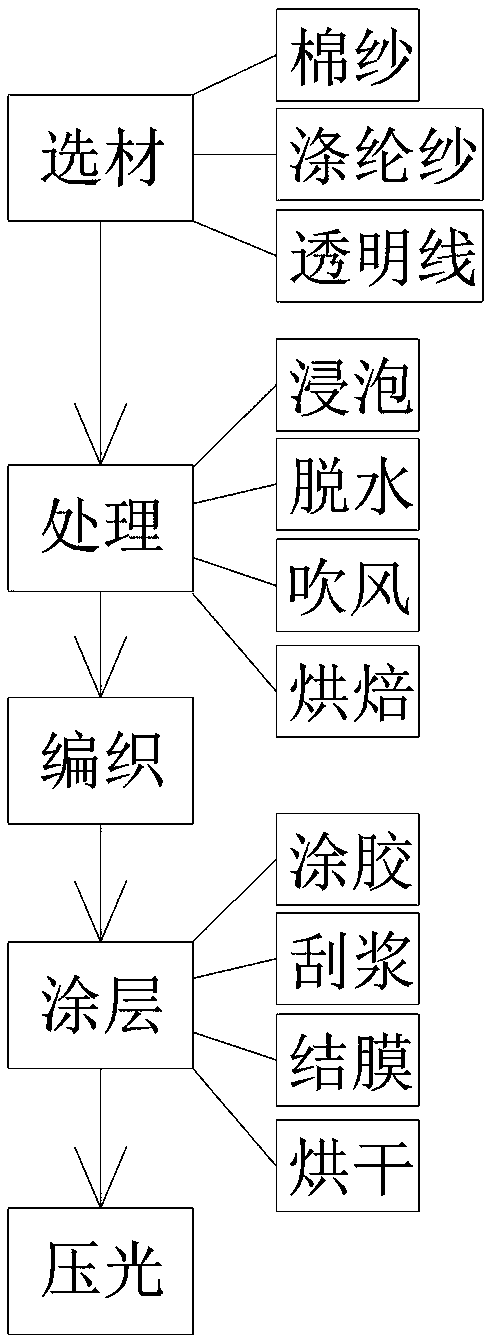

[0026] Embodiment 1: as figure 1 Shown, a kind of manufacture method of anti-counterfeit trademark webbing, comprises the following steps:

[0027] A. Material selection, choose cotton yarn and polyester yarn as warp yarn, and choose transparent thread as weft yarn.

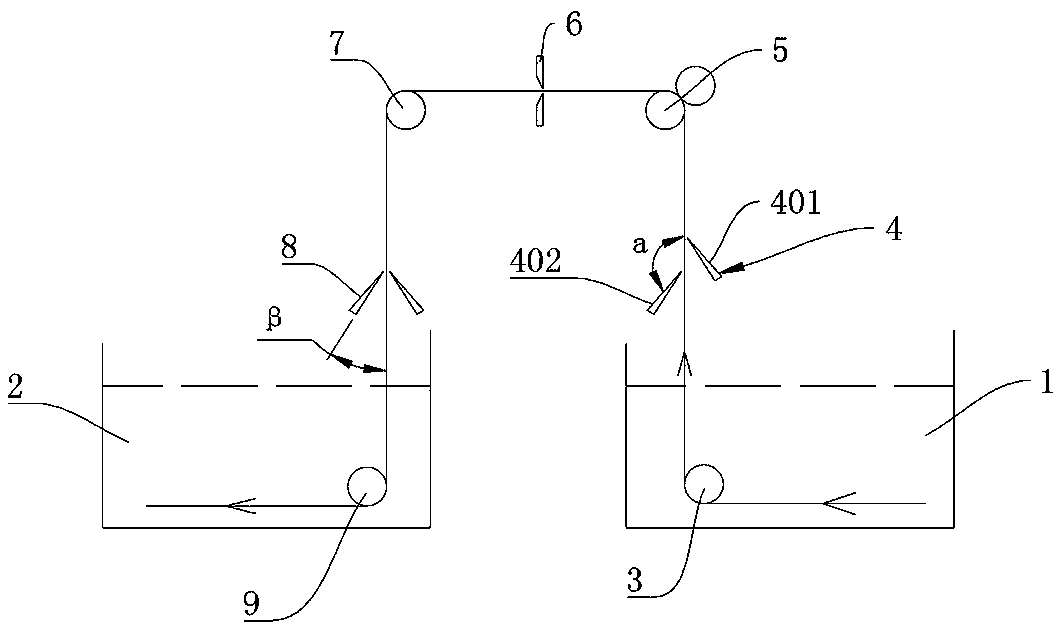

[0028] B, treatment, the cotton yarn is soaked in the anti-counterfeiting solution and then dehydrated and dried; the anti-counterfeiting solution includes the following components in parts by weight: 2 parts of anti-counterfeiting material, 95 parts of water, 2 parts of resin, and 1 part of color-fixing agent. The treatment method is as follows: After mixing cotton yarn with water and anti-counterfeiting materials, heat to 60°C under shaking, and keep warm for 20 minutes; after adding the color fixing agent, continue to shake at 60°C, keep warm for 25 minutes, finally add resin and continue to shake at 70°C, keep warm 30min. The method of dehydration and drying is as follows: after dehydrating the soaked cotto...

Embodiment 2

[0033] Embodiment 2: a kind of manufacture method of anti-counterfeit trademark webbing, comprises the following steps:

[0034] A. Material selection, choose cotton yarn and polyester yarn as warp yarn, and choose transparent thread as weft yarn.

[0035]B, treatment, the cotton yarn is soaked in the anti-counterfeiting solution and then dehydrated and dried; the anti-counterfeiting solution includes the following components in parts by weight: 3 parts of anti-counterfeiting material, 95 parts of water, 1 part of resin, and 1 part of color-fixing agent. The treatment method is as follows: After mixing cotton yarn with water and anti-counterfeiting materials, heat to 65°C under shaking, and keep warm for 20 minutes; after adding the color fixing agent, continue to shake at 70°C, keep warm for 20 minutes, finally add resin and continue to shake at 70°C, keep warm 35min. The method of dehydration and drying is as follows: after dehydrating the soaked cotton thread, it is blown ...

Embodiment 3

[0039] Embodiment 3: a kind of manufacture method of anti-counterfeit trademark webbing, comprises the following steps:

[0040] A. Material selection, choose cotton yarn and polyester yarn as warp yarn, and choose transparent thread as weft yarn.

[0041] B, treatment, the cotton yarn is soaked in the anti-counterfeiting solution and then dehydrated and dried; the anti-counterfeiting solution includes the following components in parts by weight: 3 parts of anti-counterfeiting material, 90 parts of water, 4 parts of resin, and 3 parts of color-fixing agent. The treatment method is as follows: After mixing cotton yarn with water and anti-counterfeiting materials, heat to 60°C under shaking, and keep warm for 15 minutes; after adding the color fixing agent, continue to shake at 70°C, keep warm for 25 minutes, finally add resin and continue to shake at 60°C, keep warm 35min. The method of dehydration and drying is as follows: after dehydrating the soaked cotton thread, it is blo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com