Novel prefabricated slab and construction method of prefabricated slab and beam connection

A construction method and technology of prefabricated panels, which are applied to floors, building components, buildings, etc., can solve the problems of complicated connection between prefabricated panels and beams, slow construction, etc., and achieve the effect of simple and convenient construction and quick installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

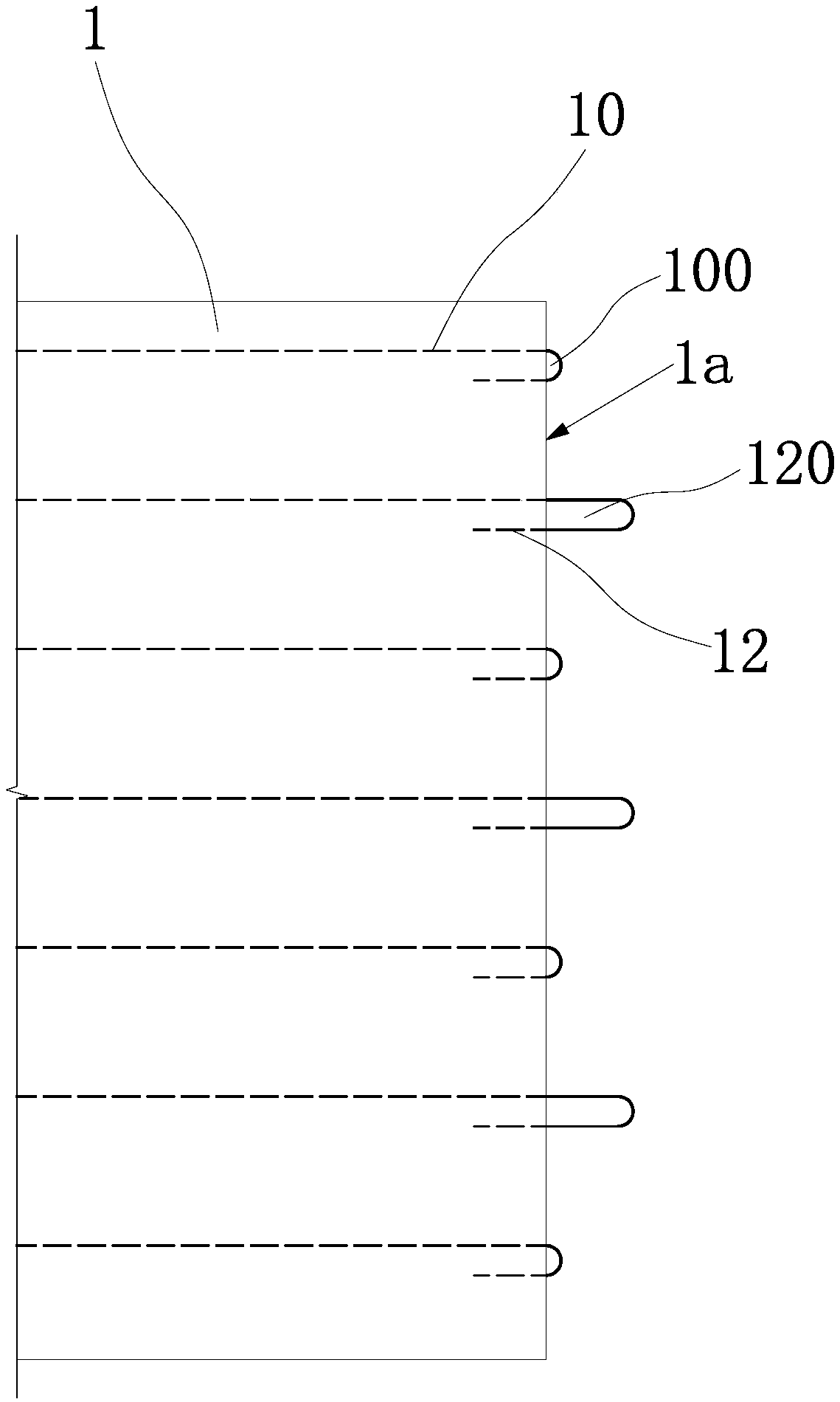

[0029] Such as figure 1 with figure 2 As shown, the present invention provides a novel prefabricated slab, comprising a prefabricated slab 1, the prefabricated slab has a plate rib 10 and a slab bottom rib 12 inside, and the end face connecting the prefabricated slab and the beam is defined as the joint surface 1a, and the prefabricated slab A plurality of plate gluten bars 10 in the panel extend out of the joint surface and form a first ring structure 100 , and a plurality of plate bottom ribs in the prefabricated panel extend out of the joint plane and form a second ring structure 120 . When making prefabricated slabs, both the slab bottom reinforcement 12 and the slab gluten 10 are made into steel bars with connecting rings and exposed. Reinforcing bar, used for the connection of steel bars 3 for panel surface connection, the connection between prefabricated slab and beam, and the connection mode between prefabricated slab and prefabricated slab will be described in detai...

Embodiment 2

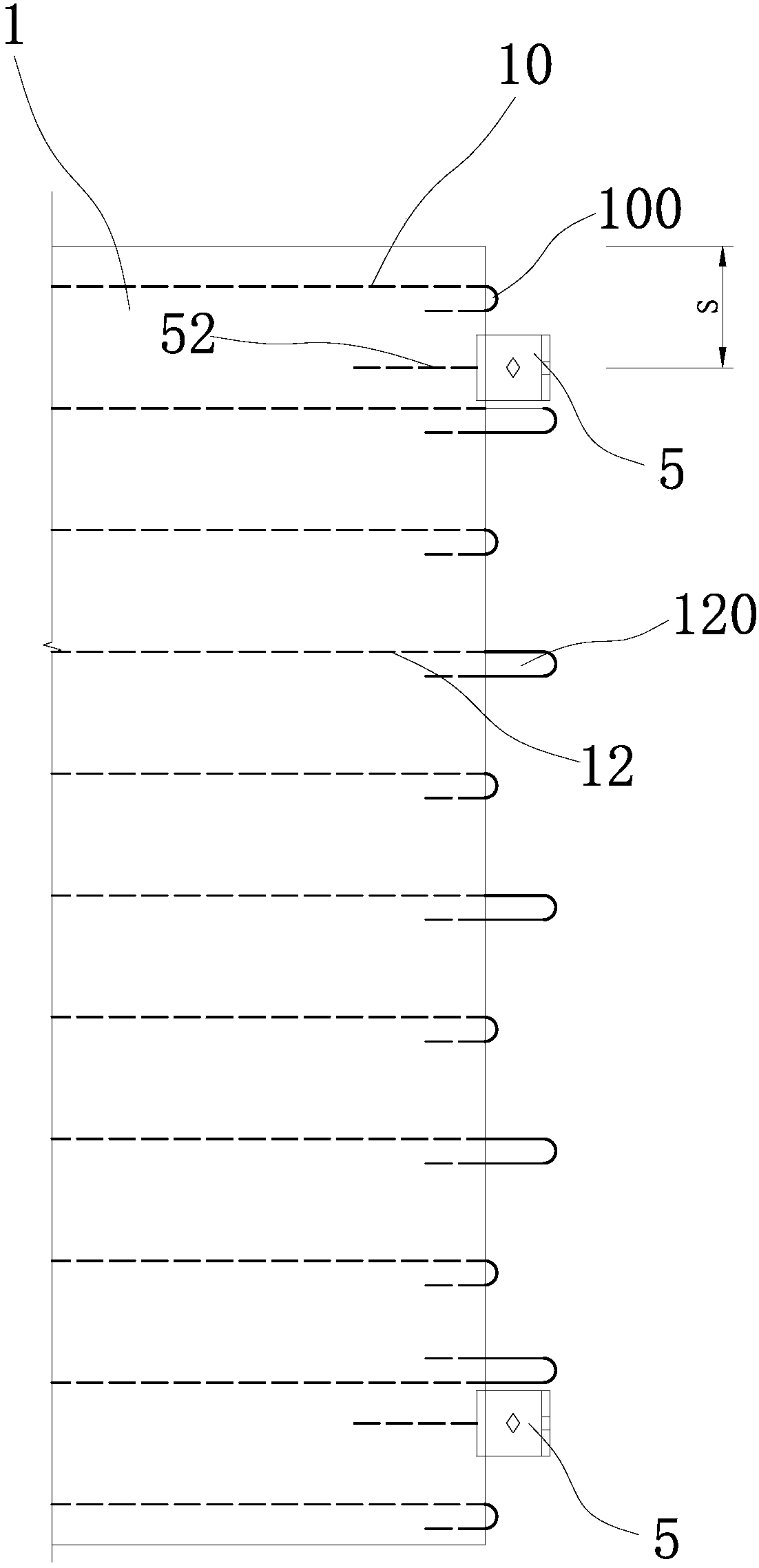

[0035] refer to image 3 with Figure 4 , this embodiment provides a new type of prefabricated slab, the prefabricated slab is roughly the same structure as the prefabricated slab in Embodiment 1, the difference is that two groove-shaped The connecting piece 5 is set at a certain distance between the two trough-shaped connecting pieces 5 on the same end. One side plate of the said trough-shaped connecting piece 5 is pre-buried in the prefabricated panel, and the other side plate is exposed on the joint surface In addition, connecting bolt holes 50 are reserved on the bottom plate and the exposed side plate of the groove-shaped connector 5 . Wherein the side plate pre-embedded in the prefabricated slab can also be pre-embedded in the prefabricated slab through the pre-embedded steel bars 52 . refer to Figure 5 , the connecting bolt hole 50 on the base plate is used for connecting with the beam, and the connecting bolt hole 50 on the side plate exposed outside the joint surf...

Embodiment 3

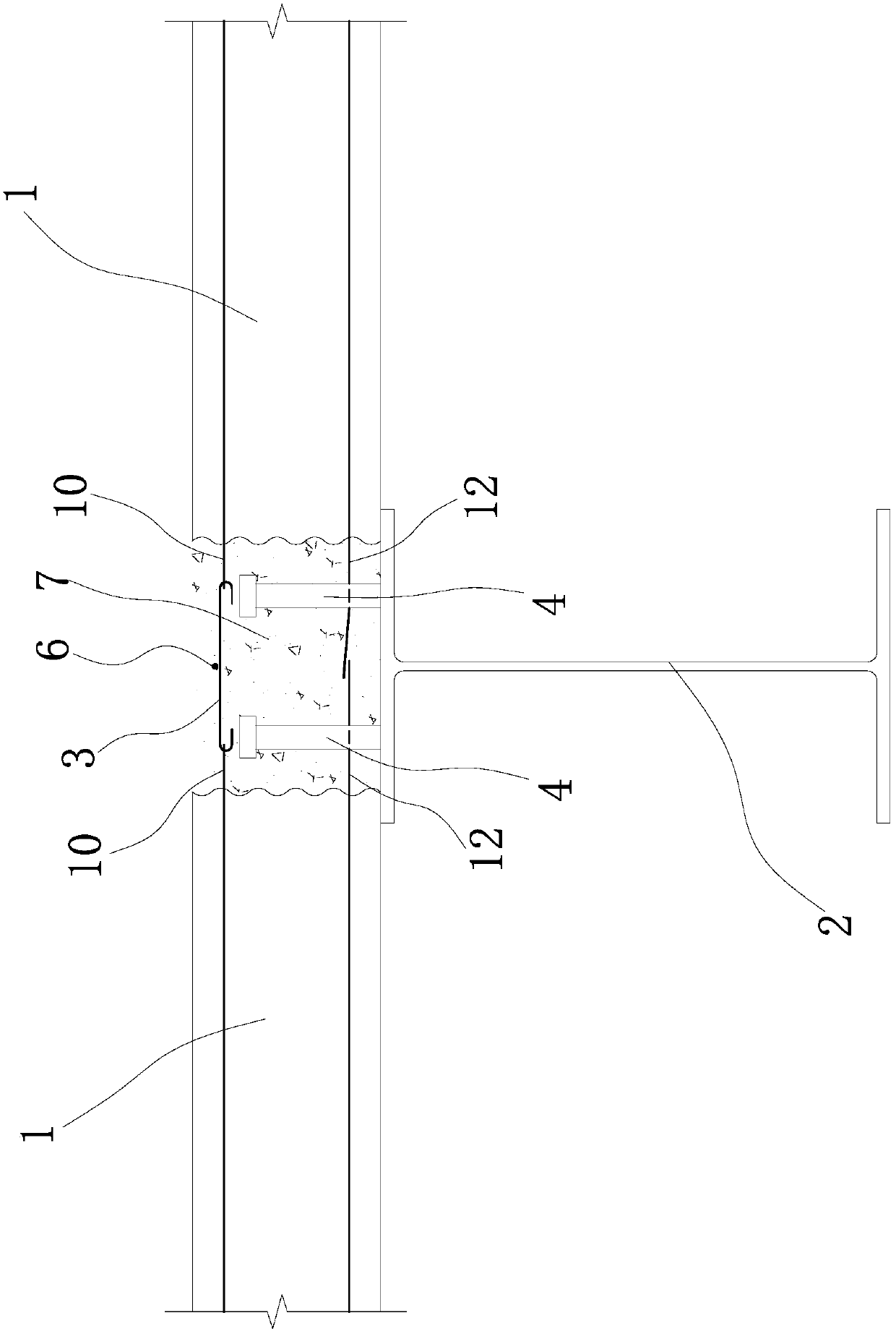

[0039] The present invention also provides a construction method for connecting prefabricated slabs and beams, wherein the beams can be steel beams or concrete beams. The steel beams are taken as an example below for illustration. figure 2 with Image 6 , figure 2 with Image 6 Shown in is the schematic diagram that prefabricated slab 1 and beam 2 provided in embodiment 1 are connected, and its construction method comprises the following steps:

[0040] S1. Provide a beam 2 and a prefabricated slab 1, wherein the prefabricated slab is the prefabricated slab in Embodiment 1, and the prefabricated slab 1 has a first ring structure 100 directly formed by the slab gluten and a second ring directly formed by the slab bottom rib Shaped structure 120, the beam is pre-welded with shear connectors 4;

[0041] S2. Hoist the prefabricated slab 1. After hoisting, connect the first annular structure 100 on the two prefabricated slabs with the panel surface connecting steel bar 3, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com