Capacitive casing end screen signal detection device

A capacitive bushing and signal detection technology, applied in the direction of testing dielectric strength, etc., can solve the problems of potential safety hazards, large signal attenuation, low detection efficiency, etc., and achieve good applicability, small signal attenuation, and high detection efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

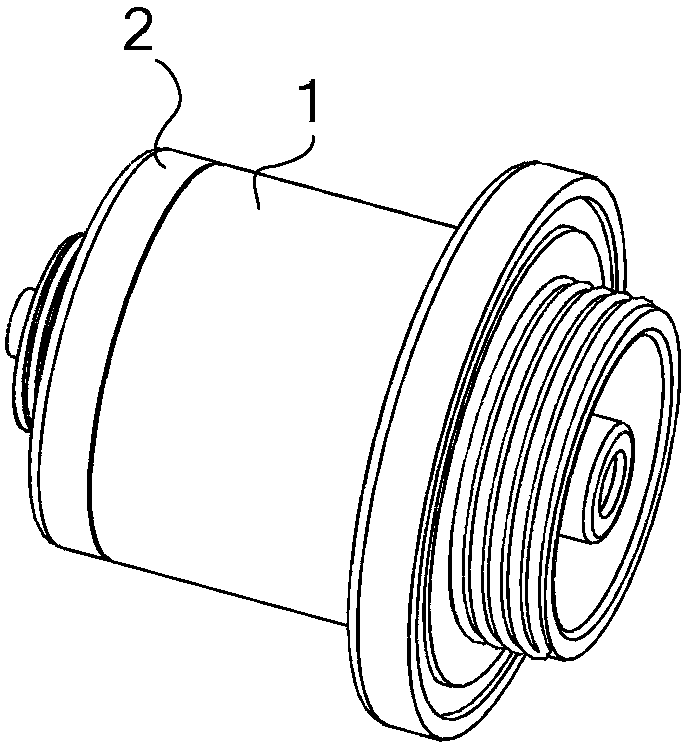

[0018] Such as figure 1 As shown, a capacitive bushing end screen signal detection device includes a signal acquisition device 1 and a signal processing device 2 that are threaded.

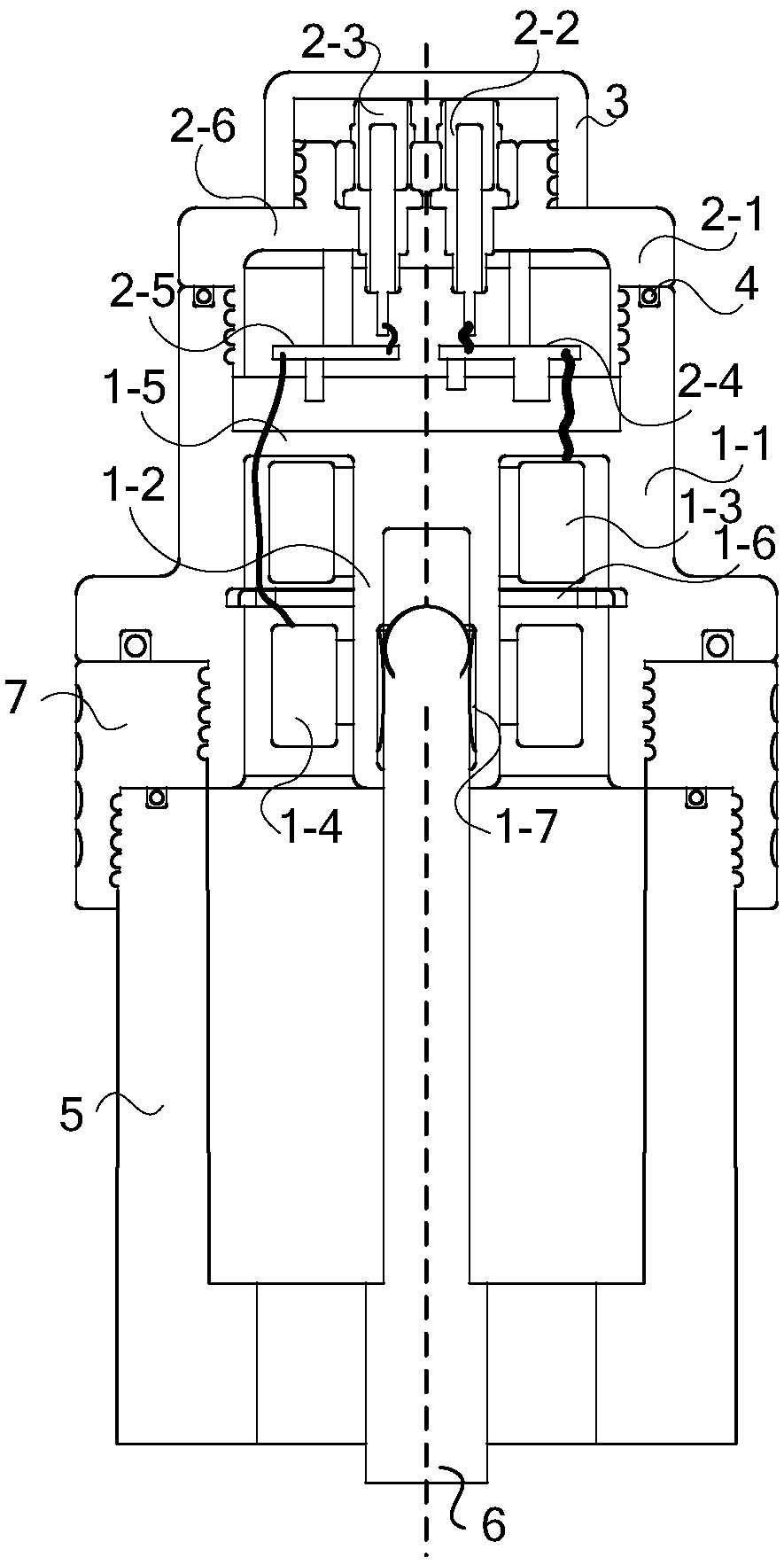

[0019] Such as figure 2 As shown, the signal acquisition device 1 includes a first metal shell 1-1, an end screen terminal 1-2, a high frequency partial discharge sensor 1-3 and a low frequency dielectric loss sensor 1-4.

[0020] The first metal shell 1-1 and the last screen terminal 1-2 are cylindrical, and the last screen terminal 1-2 is located in the first metal shell 1-1, and is integrally washed with the first metal shell 1-1. The last screen terminal 1-2 is connected to the first metal shell 1-1 through the connection platform 1-5, and the connection platform 1-5 closes one end of the last screen terminal 1-2, and the last screen terminal 1- 2 and the first metal shell 1-1 form an annular cavity.

[0021] A horizontal annular baffle 1-6 of insulating material is arranged in the annular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com