Method for detecting pollution of contact surface of mask and mask table

A technology of mask plate and mask table, which is applied to the photoplate making process of pattern surface, the original used for photomechanical processing, and the exposure device of photoplate making process, etc. It can solve the problem of out of focus, uneven placement of mask plate, mask Membrane platform is polluted and other problems, so as to reduce misjudgment and missed judgment, and achieve accurate detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

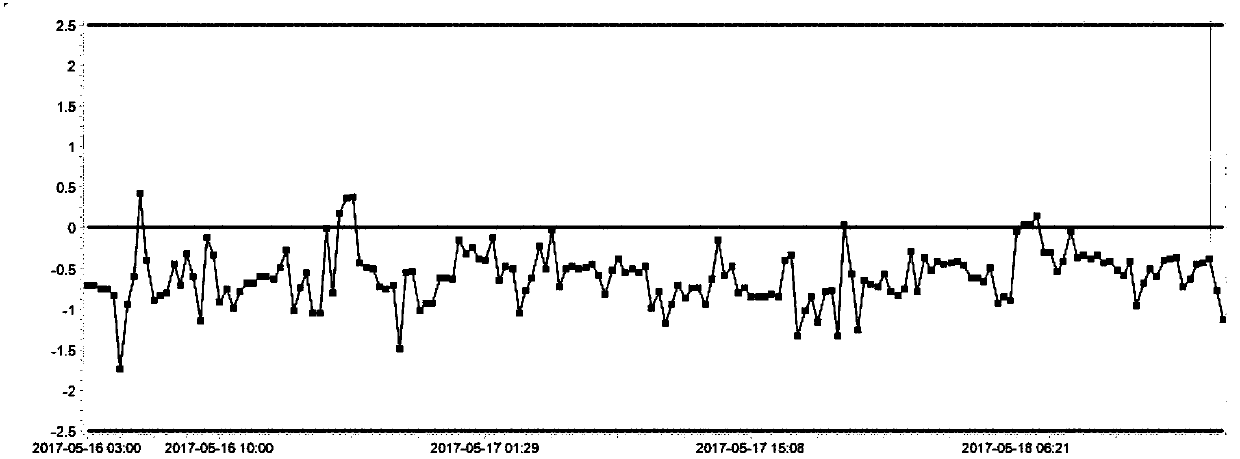

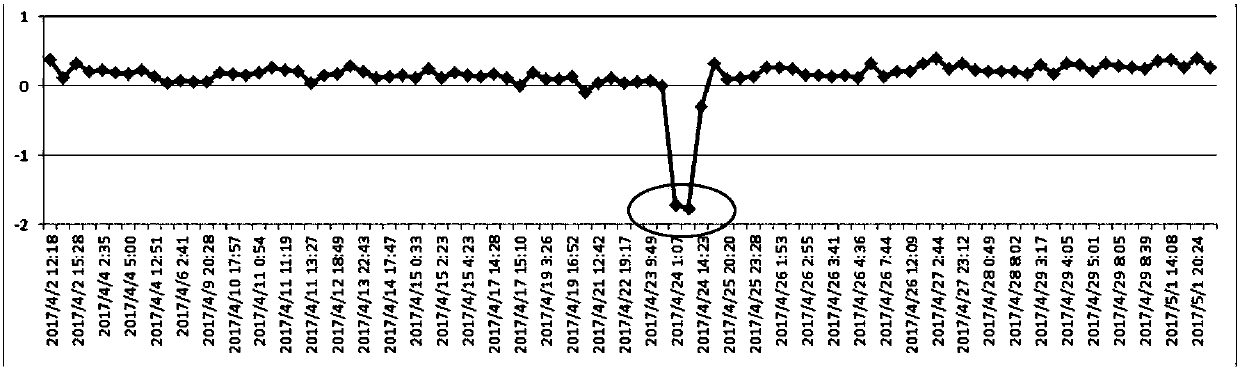

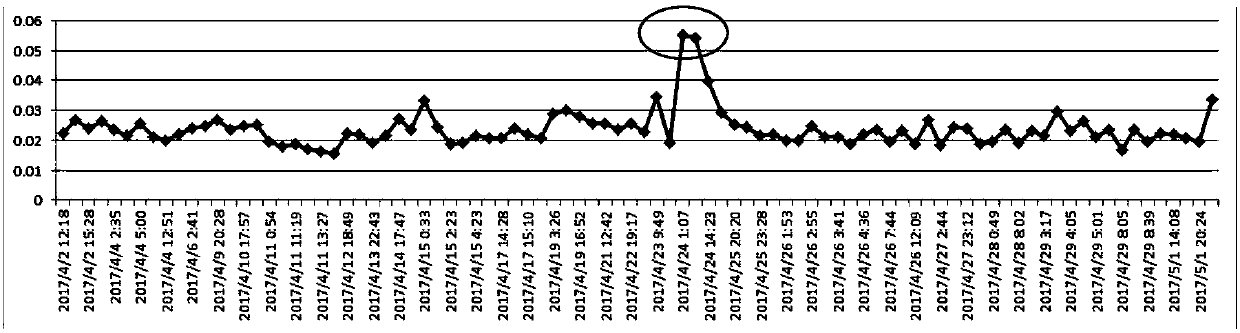

[0023] The method for detecting the contamination of the contact surface between the mask plate and the mask table proposed by the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments. Advantages and features of the present invention will be apparent from the following description and claims. It should be noted that all the drawings are in a very simplified form and use imprecise scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

[0024] The inventors of the present application found that it is difficult to monitor in real time when there is contamination on the contact surface between the existing mask plate and the mask stage.

[0025] To this end, the present application provides a method for detecting contamination of the contact surface between a mask plate and a mask table, comprising the following steps:

[0026] S1:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com