End cover with brake for servo motor, and braking method for servo motor

A technology of servo motors and brakes, applied in the direction of brake types, axial brakes, brake actuators, etc., can solve the problems of increasing assembly steps and overall installation difficulty, increasing overall volume and occupied space, and affecting braking stability. , to achieve the effects of improving production efficiency, reducing attenuation, and reducing assembly steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings, but it is not intended to limit the protection scope of the present invention.

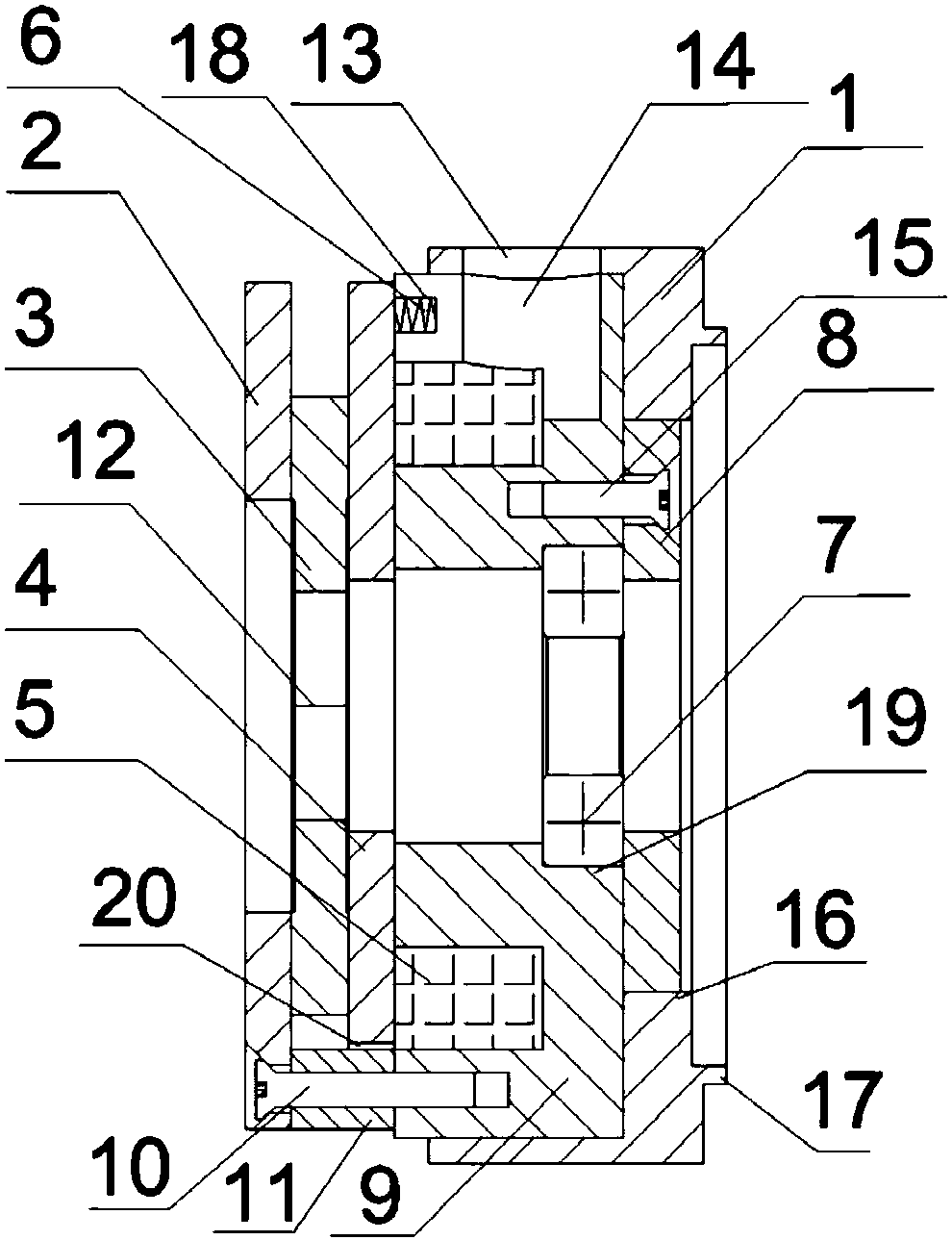

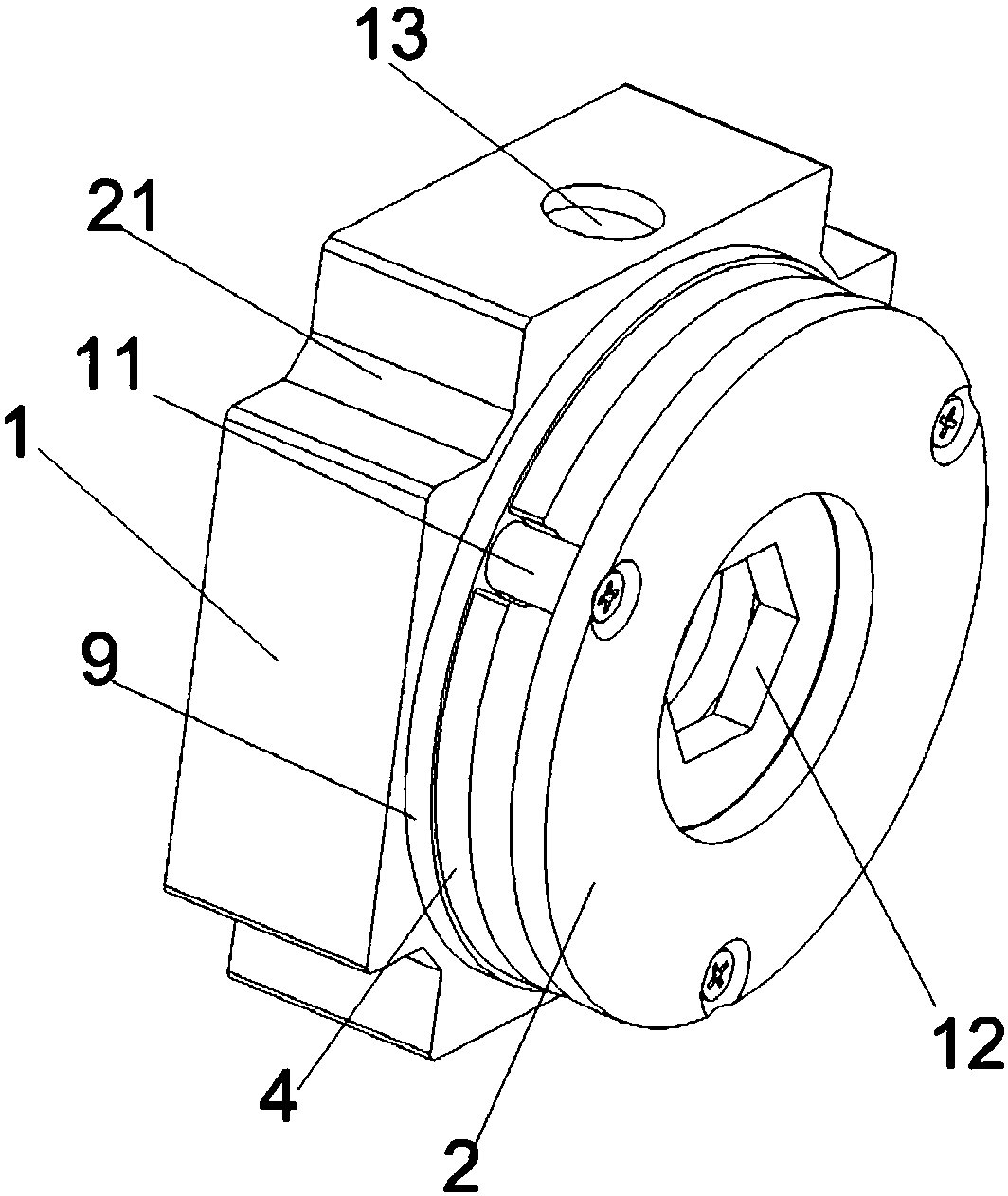

[0028] Such as figure 1 and 2 As shown, an end cover for a servo motor with a brake includes an end cover body 1 on which a brake is installed. The brake includes a yoke 9, an armature 4, a brake disc 3, a static plate 2, a spring 6 and a coil 5. The yoke 9 is embedded in the end cover body 1, the coil 5 is located in the yoke 9, the left side of the yoke 9 is exposed outside the end cover body 1, the armature 4 is set on the left side of the yoke 9, and the brake disc 3 is located in the armature 4 on the left side, the static plate 2 is located on the left side of the brake disc 3, and the yoke 9 and the static plate 2 are connected by three screws 10. The spring 6 is located between the armature 4 and the yoke 9, and the spring 6 withstands the armature 4 to lock the brake dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com