A bridge steel plate cutting machine with complete slag removal

A cutting machine and steel plate technology, applied in welding/welding/cutting articles, manufacturing tools, metal processing, etc., can solve the problems of reducing processing efficiency and productivity, increasing labor intensity of operators, increasing operating costs and time, etc., to achieve The effect of reducing processing efficiency, expanding usability, and reducing processing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Below in conjunction with the accompanying drawings, the present invention will be described in detail through specific embodiments, but the use and purpose of these exemplary embodiments are only used to illustrate the present invention, and do not constitute any form of any limitation on the actual protection scope of the present invention, let alone The protection scope of the present invention is limited thereto.

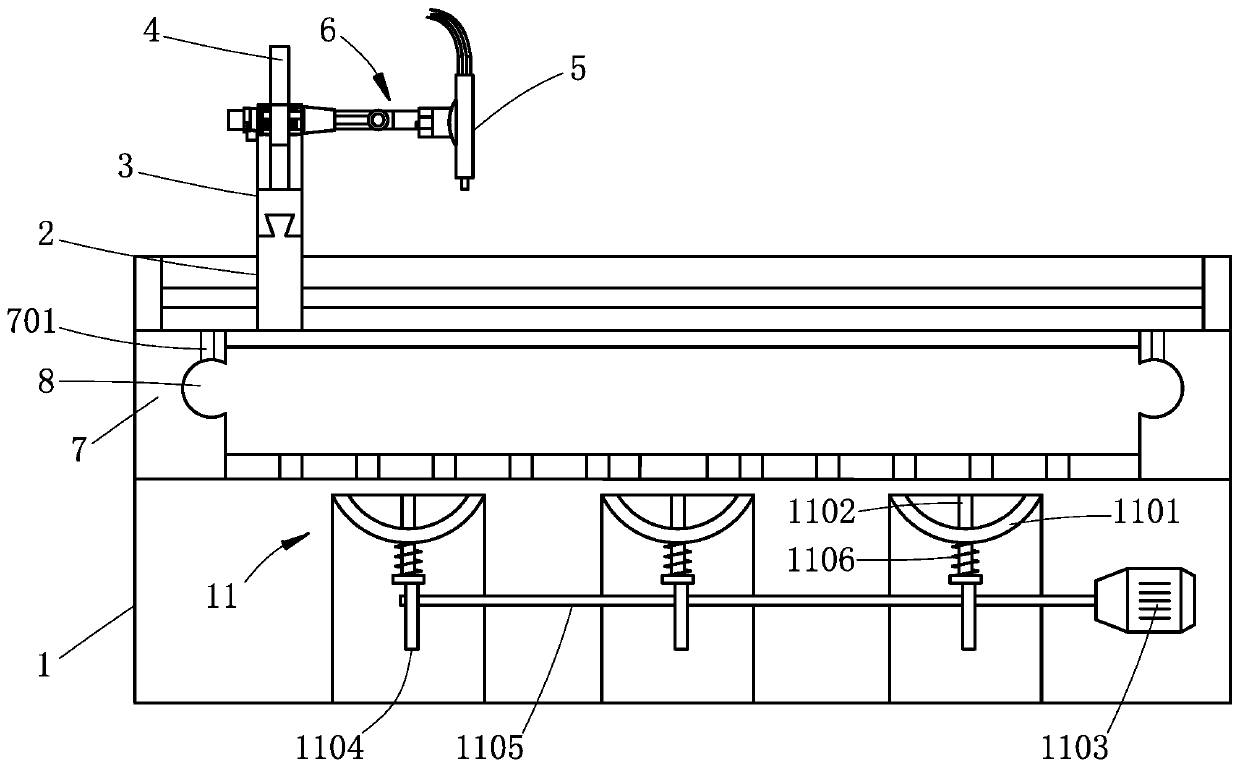

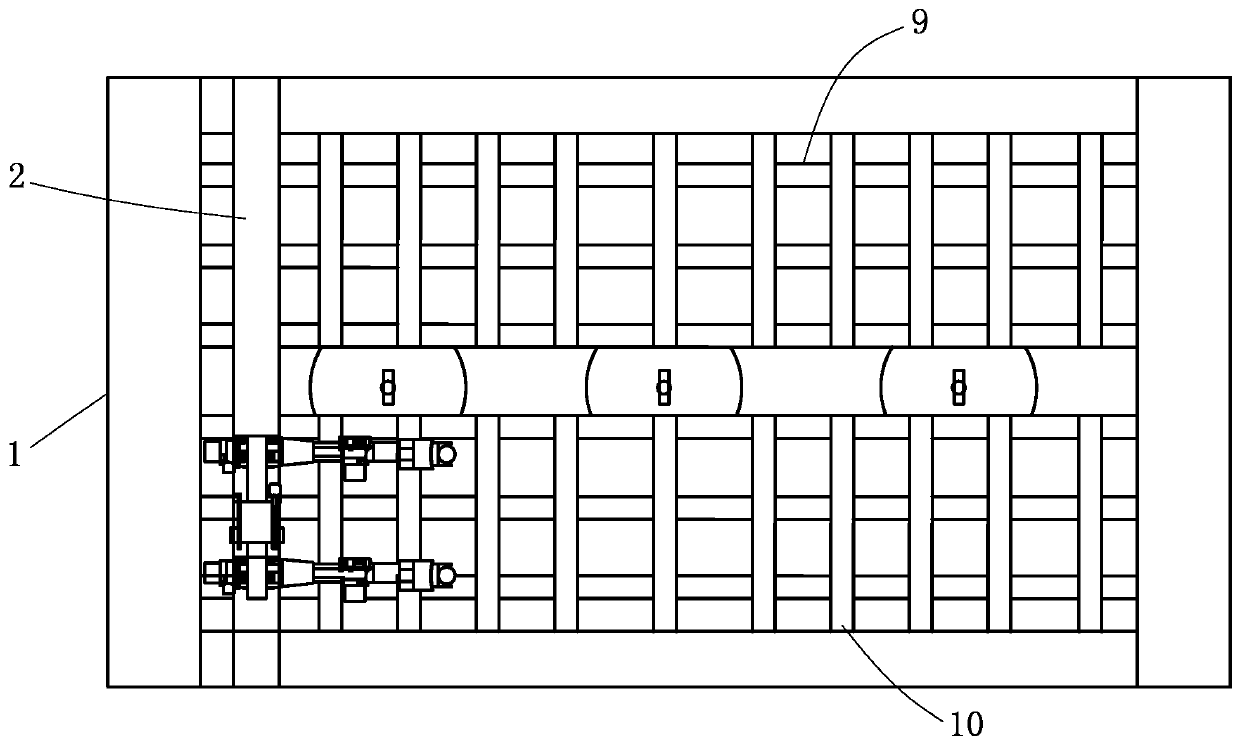

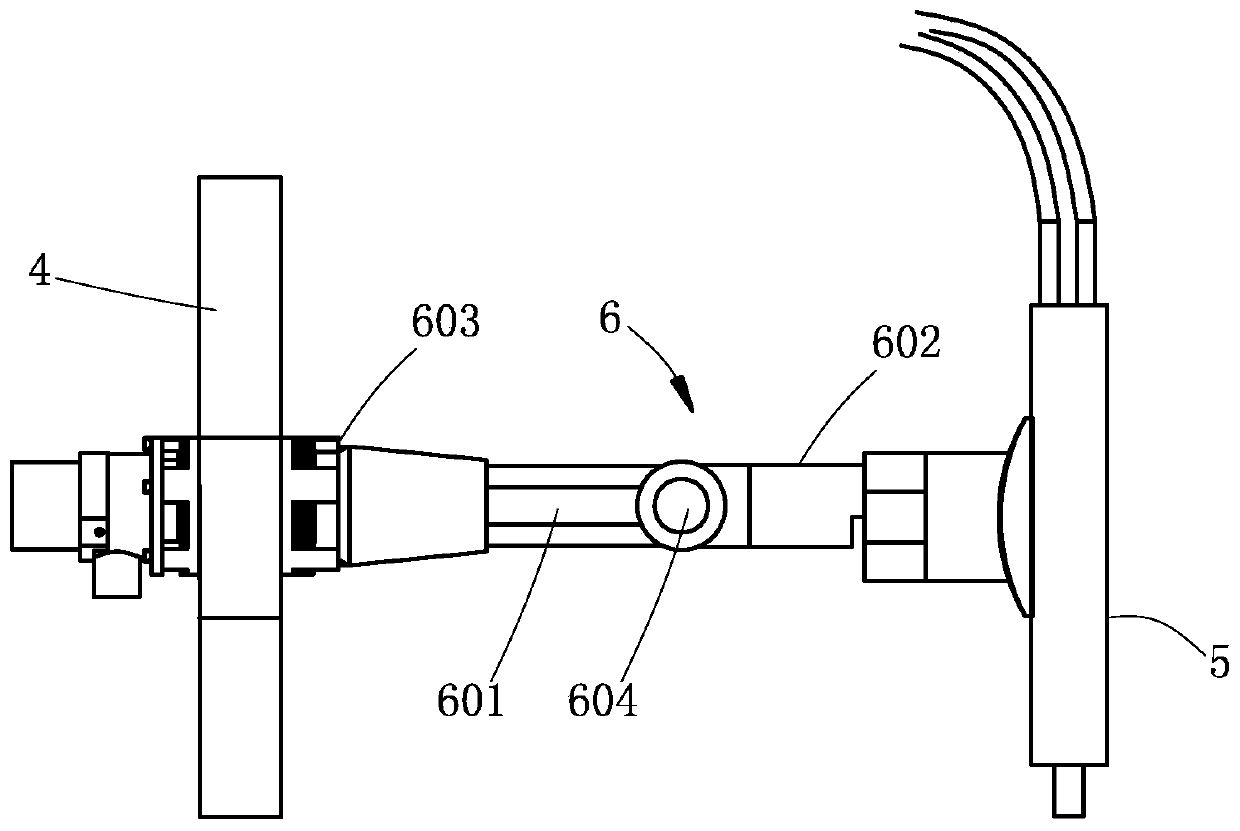

[0057] Such as Figure 1-4 Commonly shown, the present invention discloses a completely slag-removing bridge steel plate cutting machine, which includes a frame 1, on which a traverse frame 2 driven by a first power device is horizontally slidably installed, and on which the traverse frame 2 is vertically A longitudinal movement frame 3 driven by the second power unit is slidably installed, and a lifting plate 4 driven by a third power unit is vertically slidably installed on the longitudinal movement frame 3, and a cutting head 5 is installed on the lift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com