Inspection tools used for car front of the car

A clapboard and automobile technology, applied in the direction of mechanical devices, measuring devices, instruments, etc., can solve the problems of no detection of molds, etc., to achieve the effects of improving production efficiency, ensuring the pass rate, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

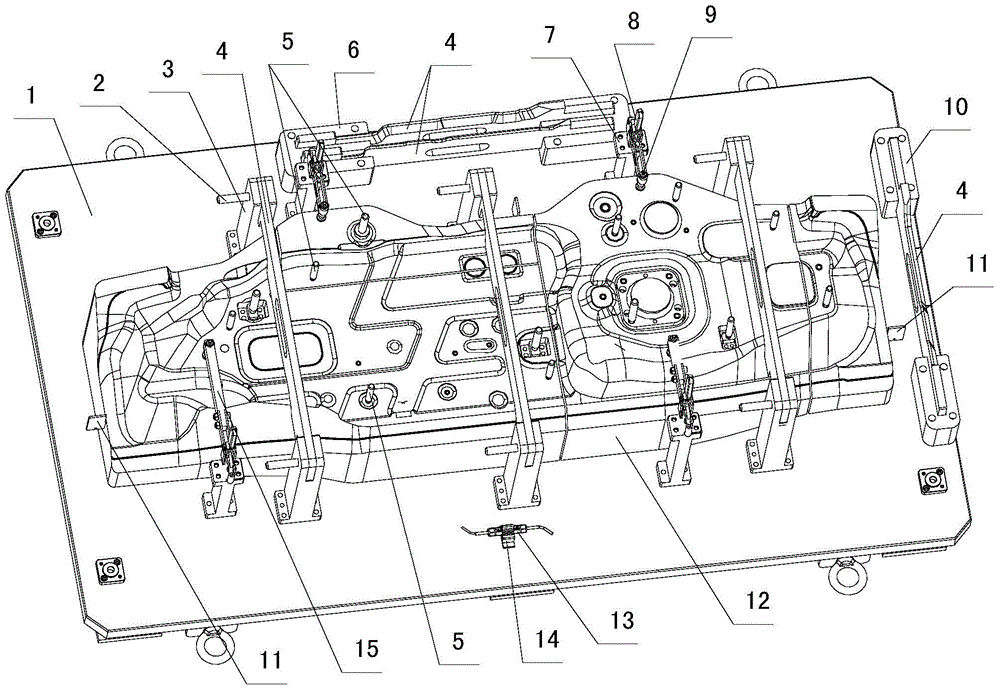

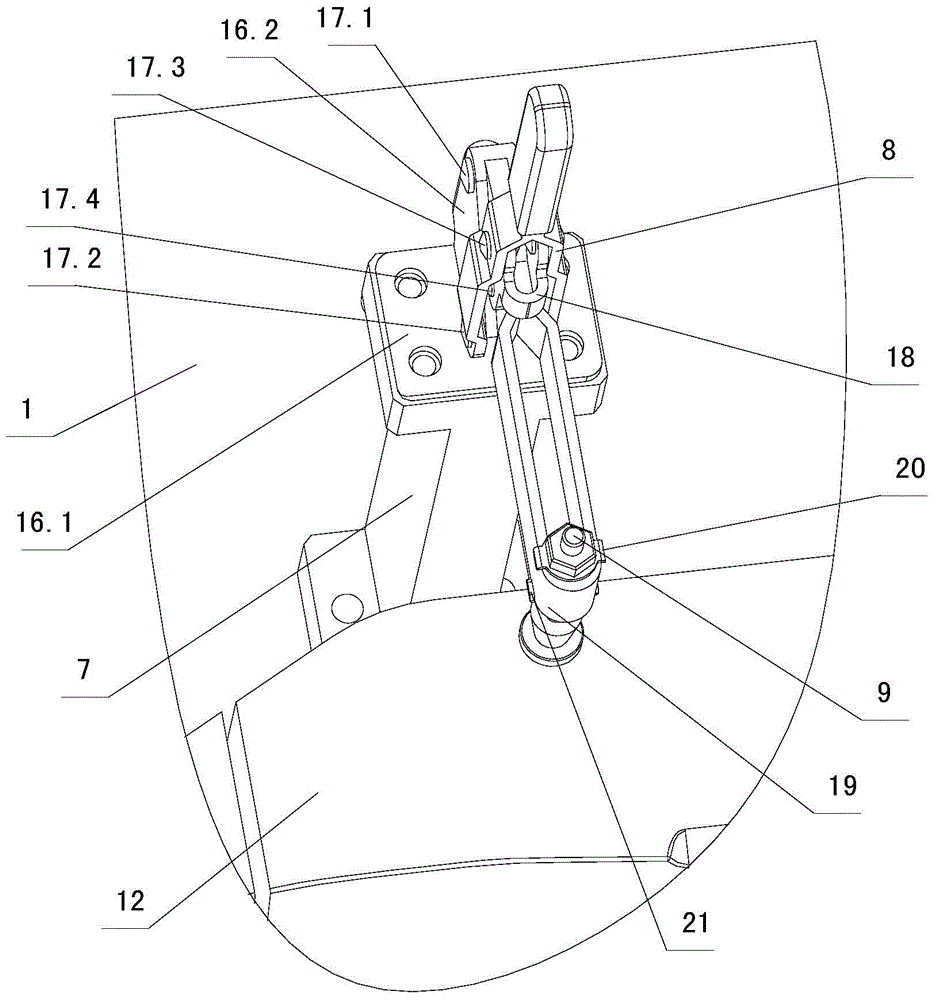

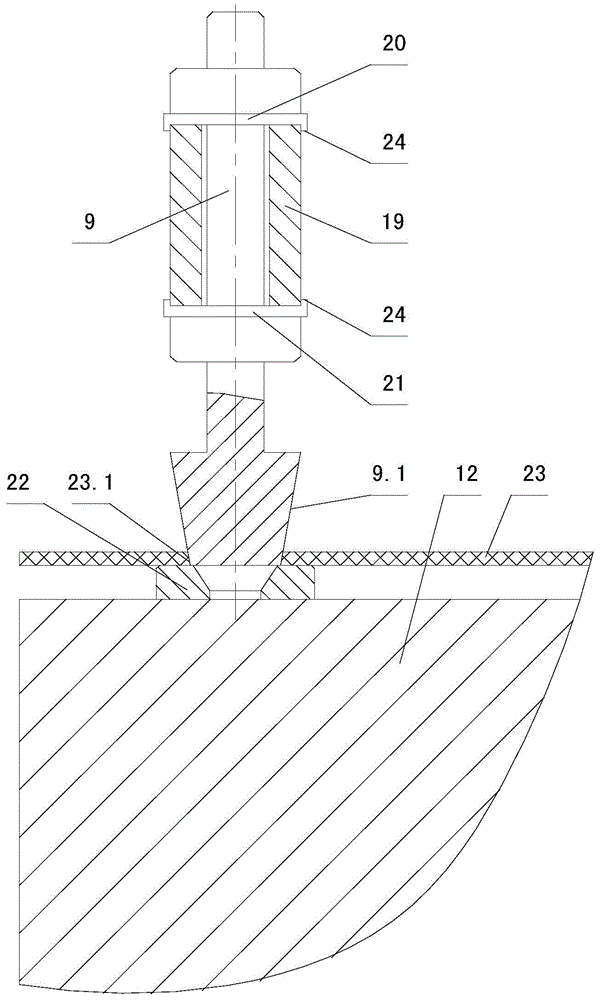

[0025] Depend on Figure 1 ~ Figure 4 As can be seen from the schematic structural diagram of the inspection tool for the vehicle dash panel of the present invention, it includes a base plate 1, a simulation block 12 combined with the large surface of the automobile dash panel 23, a locking device, and a locking device. 1. The non-pass gauge 13 for detecting surface contour, the flush gauge for detecting edge contour and the detection pin 5 for detecting function positioning holes. The analog block 12 is fixedly connected to the base plate 1, the dash panel 23 is located above the analog block 12, and the dash partition 23 is separated from the analog block 12 by a reference block 22 for the detection of the stop gauge 13. Clearance. Both the clamping device and the locking device can be detachably connected to the base plate 1, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com