Seal ring feeding device

A sealing ring and material clamping technology, which is applied in the field of sealing ring feeding devices, can solve problems such as difficult installation work, and achieve the effect of speeding up efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

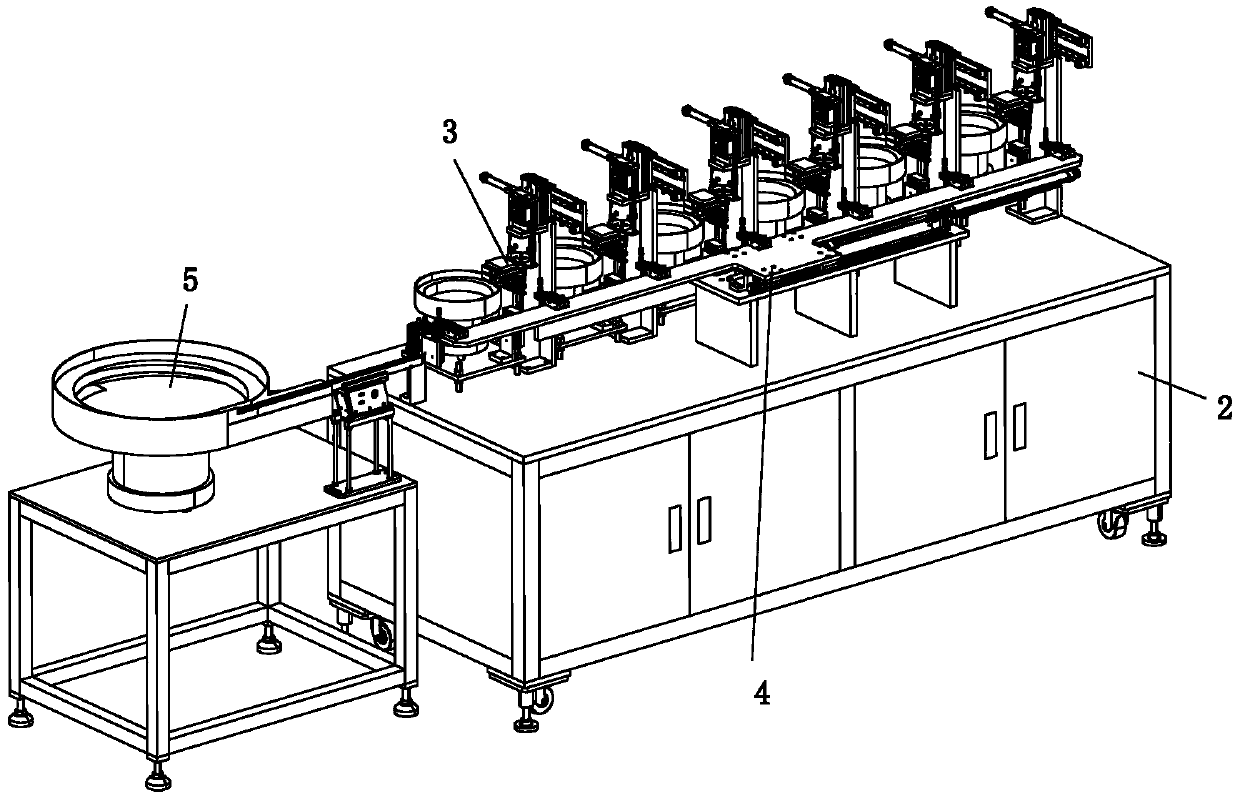

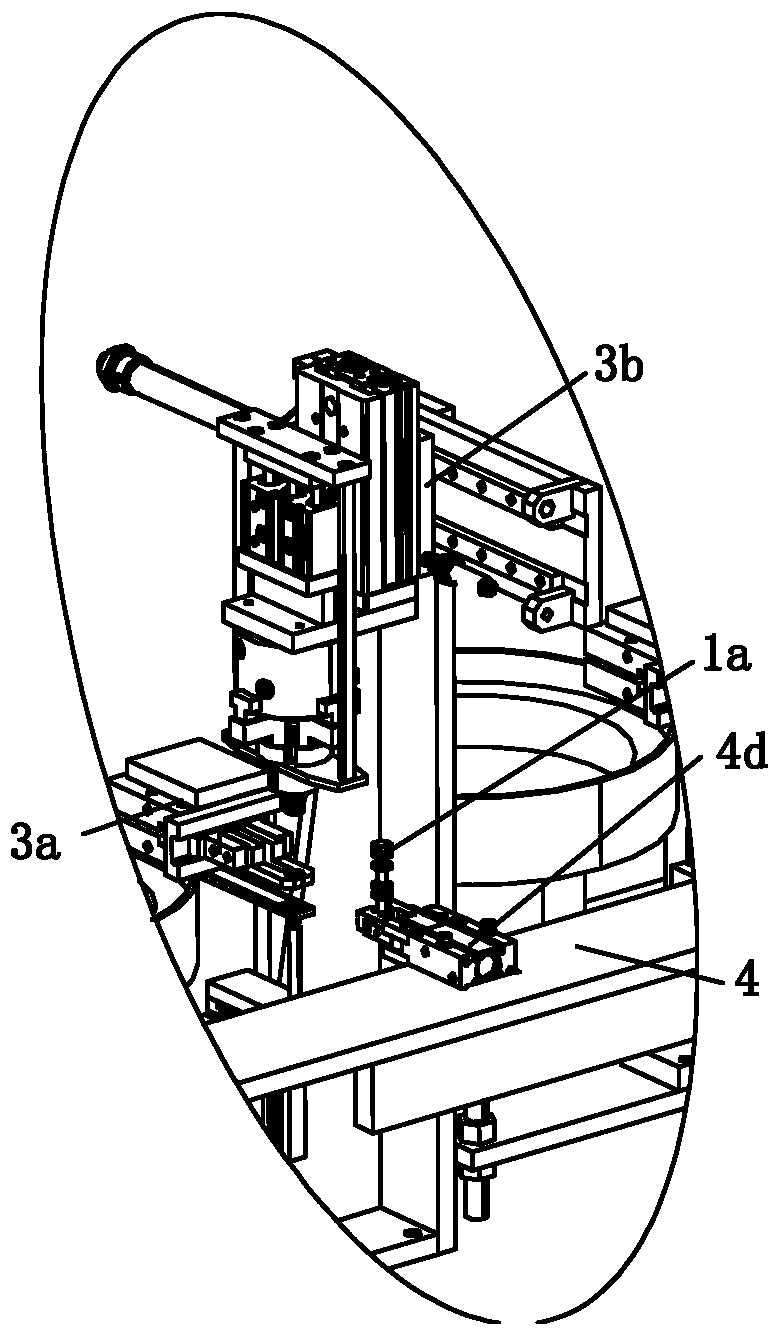

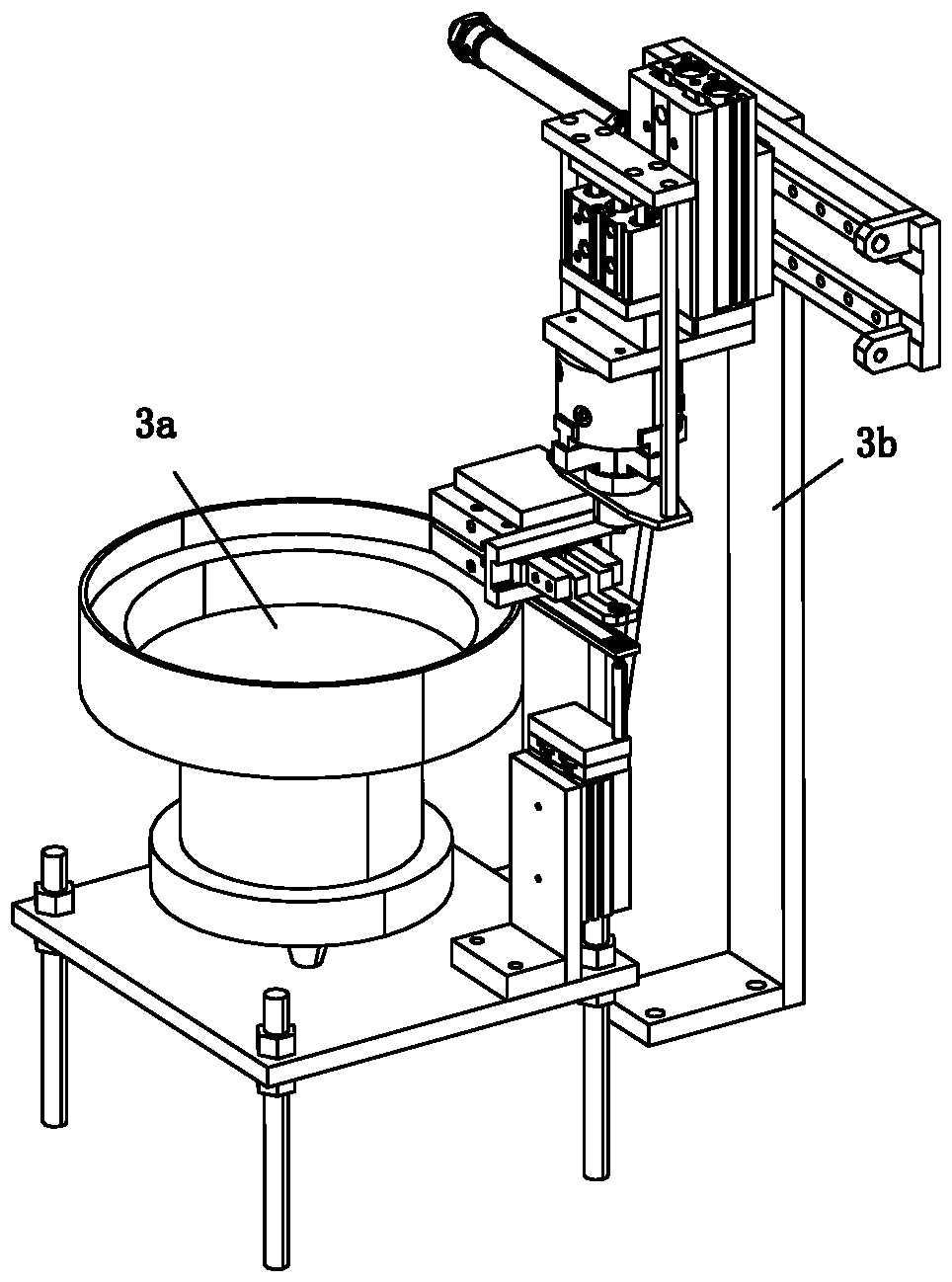

[0027] refer to Figure 1 to Figure 13 A straight-line assembly machine for valve stem sealing ring assembly shown includes an assembly table 2, which is provided with a number of sealing ring assembly mechanisms 3 distributed along a straight line at equal intervals, and on the assembly table 2 there are There is a linear multi-station transfer mechanism 4 matched with all sealing ring set mechanisms 3, and a valve stem automatic feeding mechanism 5 matching it is provided on one side of the linear multi-station transfer mechanism 4. The valve The stem automatic feeding mechanism 5 is used to transport the valve stems 1a to the linear multi-station transfer mechanism 4 in an orderly manner, and the linear multi-station transfer mechanism 4 drives multiple valve stems 1a to pass through all the sealing ring assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com