Natural gas engine ECU spraying device and control method

An injection device and engine technology, applied in engine control, fuel injection control, electrical control, etc., can solve the problems of not having the programmable function of driving waveform peak current value, less opening to the outside world, backward chips, etc., to improve cold start characteristics , low design cost and high configurability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

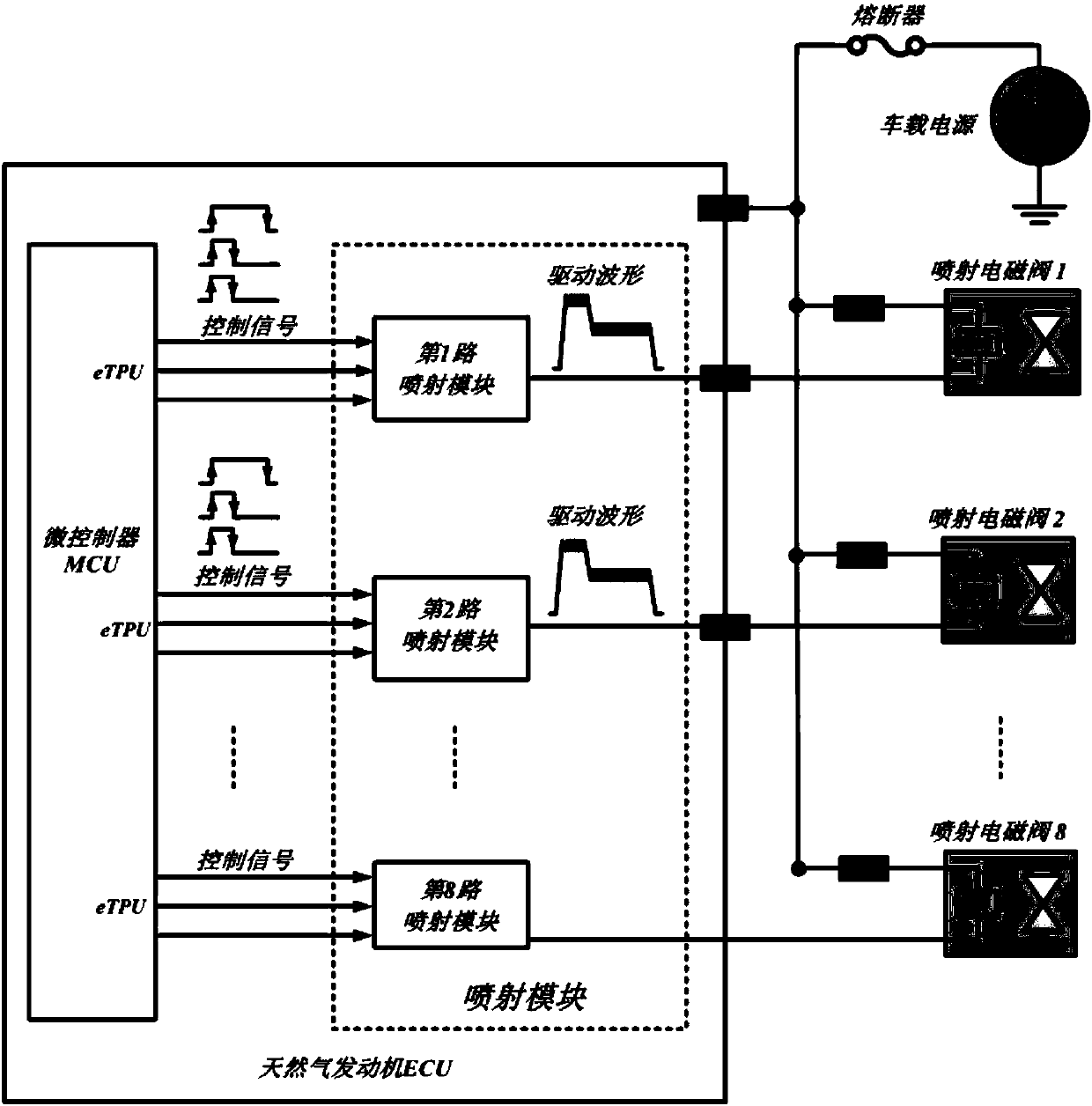

[0045] Such as figure 1 As shown, this embodiment provides a natural gas engine ECU injection device, which includes a natural gas engine ECU, an injection solenoid valve, an on-board power supply and a fuse.

[0046] The injection solenoid valve is installed upstream of the throttle body, the first end of each injection solenoid valve is connected to the vehicle power supply through a fuse, and the second end is connected to the natural gas engine ECU.

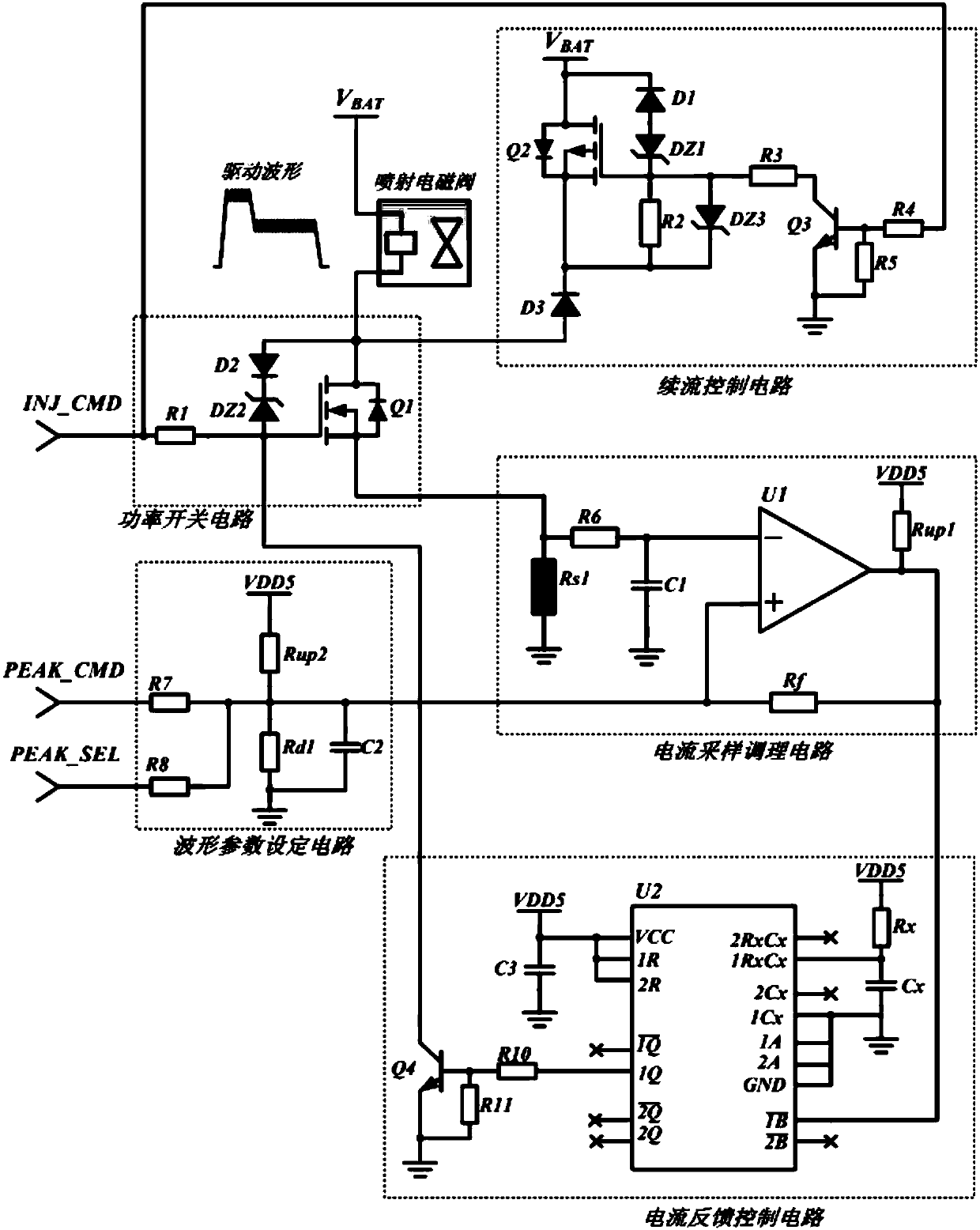

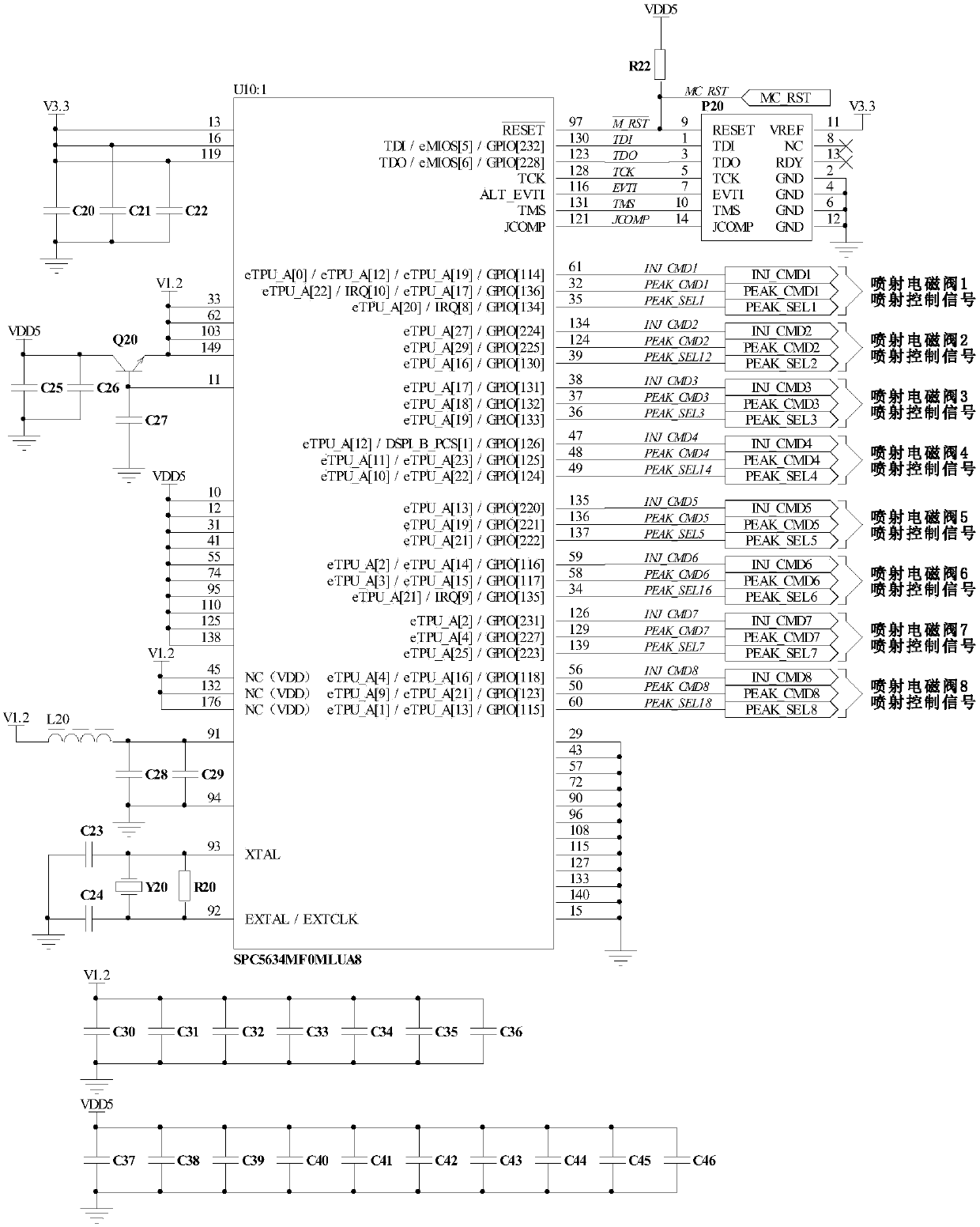

[0047] The natural gas engine ECU includes a microcontroller module and an injection module, and the time processing unit of the microcontroller module sends an injection pulse width signal, a peak position pulse width signal and a fractional current selection signal to the injection module, and the injection module The module outputs the drive waveform of the injection solenoid valve to control the injection volume of the injection solenoid valve.

[0048] The micro-controller module judges whether it is a cold start condit...

Embodiment 2

[0098] This embodiment provides a control method of a natural gas engine ECU injection device, which includes:

[0099] The microcontroller module judges whether it is a cold start condition according to the coolant temperature signal of the engine; if it is determined to be a cold start condition, then the driving waveform of the injection solenoid valve is switched from the normal waveform mode to the cold start waveform mode; if it is determined not to be In the cold start condition, keep the driving waveform of the injection solenoid valve in the normal waveform mode.

[0100] Wherein, in the normal waveform mode, the injection pulse width signal "INJ_CMD", the peak sustain pulse width signal "PEAK_CMD" and the peak current selection signal "PEAK_SEL" sent by the time processing unit in the microcontroller module, wherein the The injection pulse width signal "INJ_CMD" is used to control the start time and end time of the injection solenoid valve, and the peak maintenance p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com