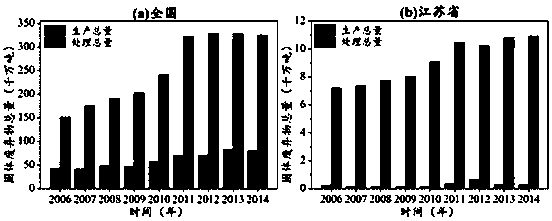

City solid waste self-maintaining smoldering treatment platform system and treatment method

A solid waste and processing platform technology, applied in the field of environmental engineering, can solve the problems of complex process, increase the difficulty of process operation, increase disposal cost, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

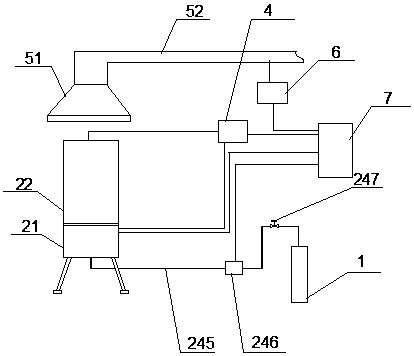

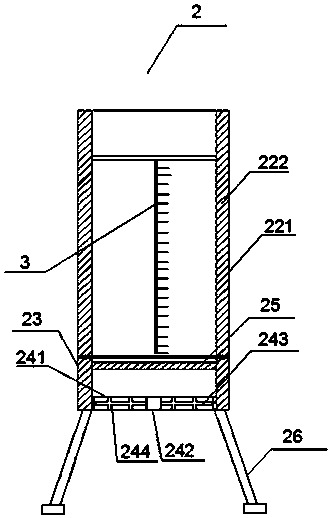

[0048] Such as Figure 2 to Figure 5 As shown, the municipal solid waste self-sustaining smoldering treatment platform system of the present invention includes a compressed gas cylinder 1, a reaction furnace 2, a data acquisition device 4, a smoke exhaust device 5, a flue gas analyzer 6, a host 7 and an ignition The controller 25, the compressed gas cylinder 1 is connected to the reaction furnace 2 through a vent pipe, and the smoke exhaust device 5 is provided above the reaction furnace 2; the reaction furnace 2 includes a furnace body 22 and a base 21, The furnace body 22 is a hollow cylinder with an outer diameter of 126 mm and a height of 100 cm. It includes a shell 221 and an insulation layer 222 arranged on the inner side wall of the shell 221. The shell 221 is made of thin stainless steel. The insulation layer 222 The thickness of the base 21 is 4mm; the base 21 includes a support body 23, a ventilation device 24, and a support bracket 26. The support body 23 is a hollow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com