Composite-planar gas heat energy exchanger

A heat energy exchanger, composite plane technology, applied in indirect heat exchangers, heat exchanger types, lighting and heating equipment, etc., can solve the problems of easy dust accumulation, poor heat exchange capacity, large flow resistance, etc. Ash, long service life, small flow resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

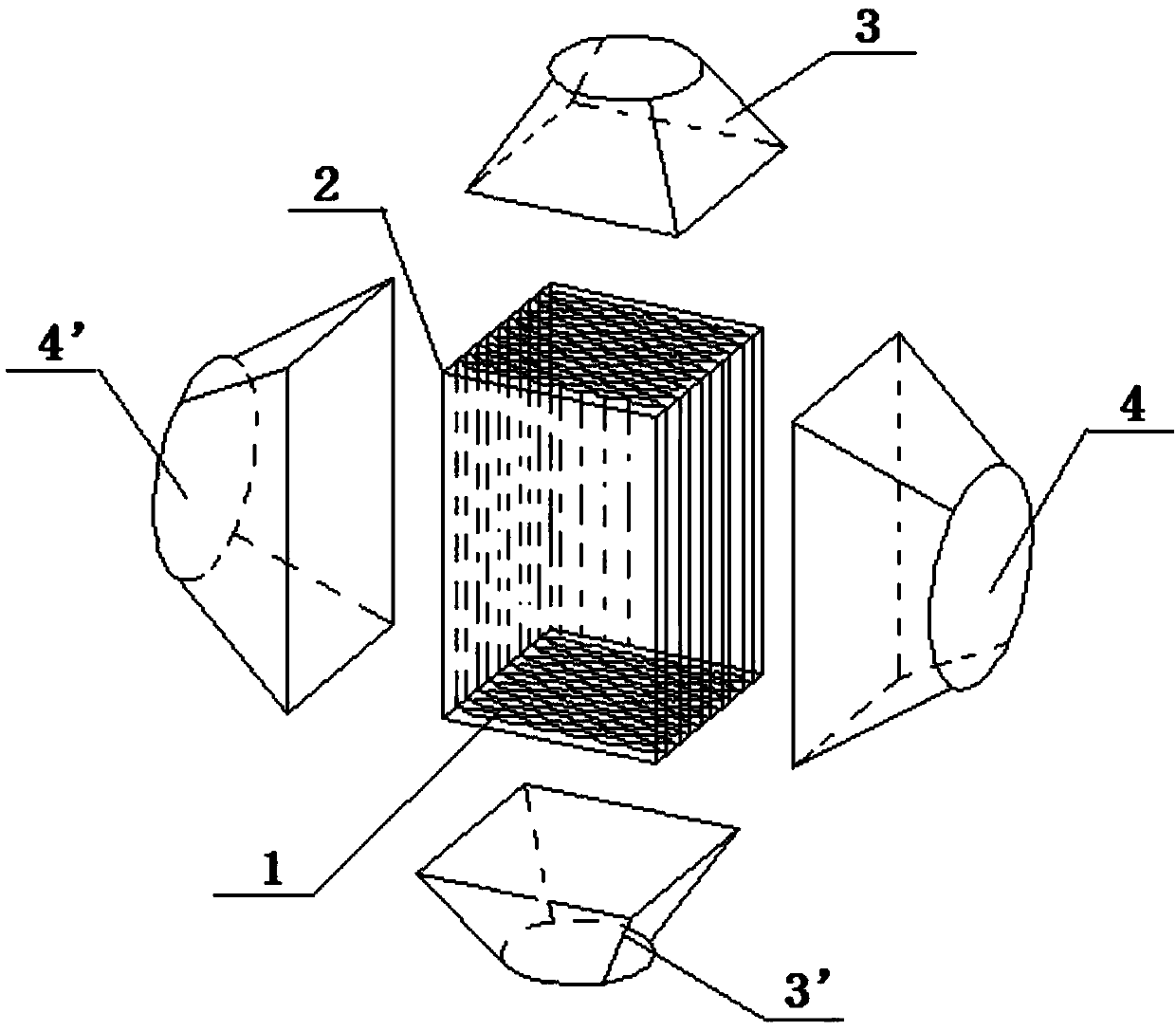

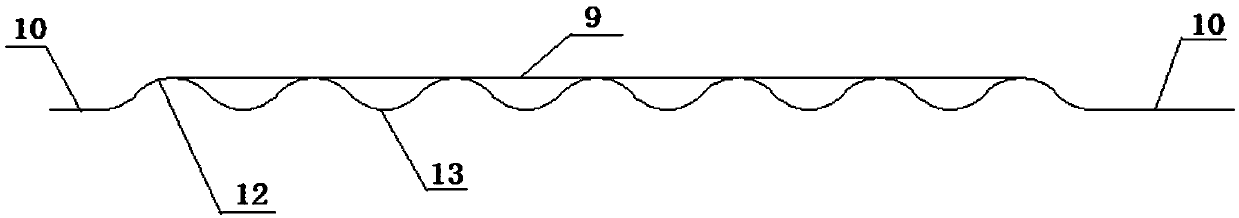

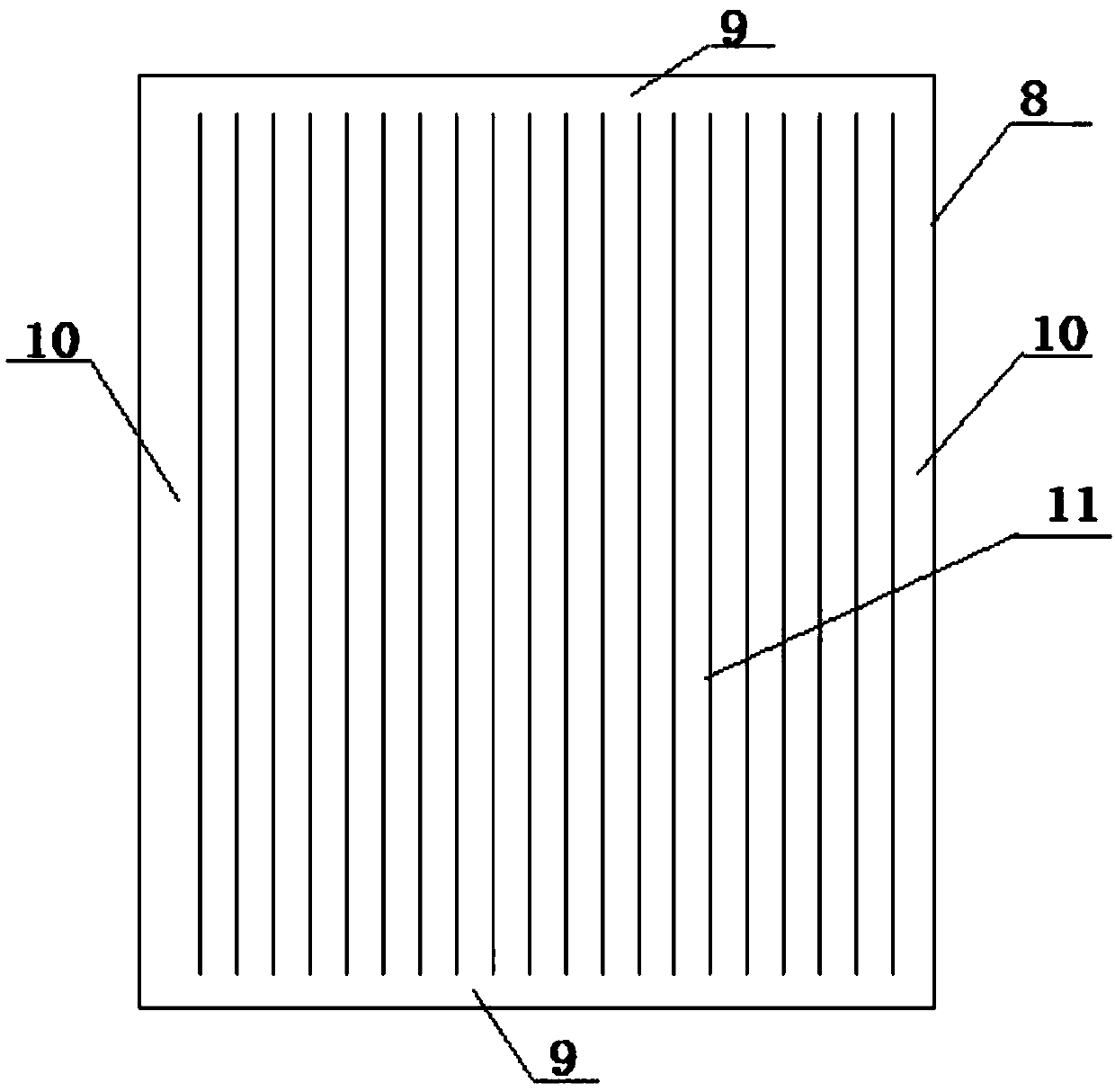

[0024] Embodiment 1: refer to figure 1 A plate heat exchanger includes: a corrugated plate heat exchange core 1, a heat exchanger shell 2, flue gas and air inlet and outlet pipelines 3, 3', 4, 4'. refer to figure 2 , 3 , the corrugated plate 8 is punched by a flat plate to form an upper and lower plane area 9, a left and right plane area 10, and a corrugated area 11, and the plate bundle 5 is welded to form a quasi-elliptical tubular passage 6 through the left and right plane areas 10, and the plate bundle 5 and the plate The bundle 5 is welded through the upper and lower planar regions 9 to form a shell-side channel 7 . refer to Figure 4 , the corrugated plate heat exchange core 1 is formed by stacking multiple groups of plate bundles 5 staggered by 1 / 2 ellipse, and the corrugated plate 8 is formed by stacking 12 peaks to 12 peaks and 13 troughs to 13 troughs. The quasi-elliptical tubular channel 6 of the plate bundle passes the flue gas, and the shell pass 7 between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com