Numerical control plasma programming method for realizing continuous cutting

A programming method and plasma technology, applied in the field of ion programming, can solve problems such as time consumption, and achieve the effect of increasing the proportion of cutting time, reducing replacement, and being easy to implement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is described in detail below in conjunction with the embodiment that accompanying drawing provides:

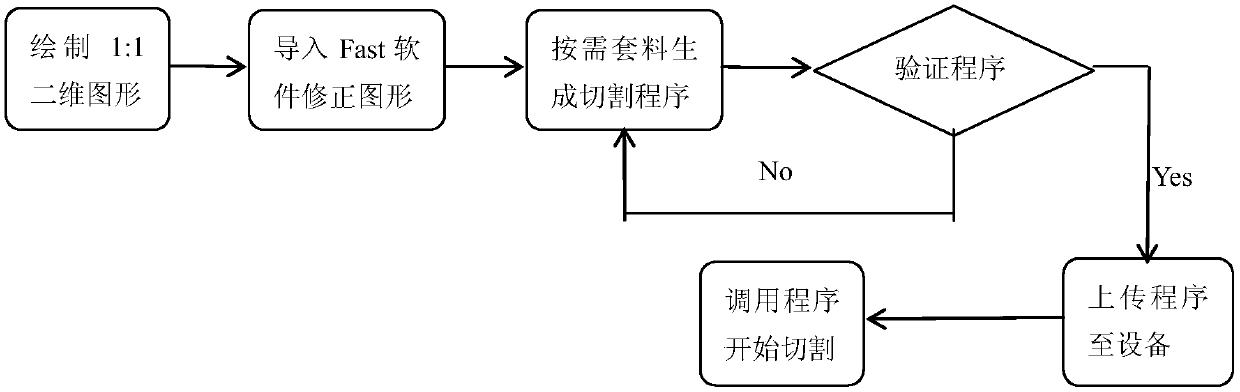

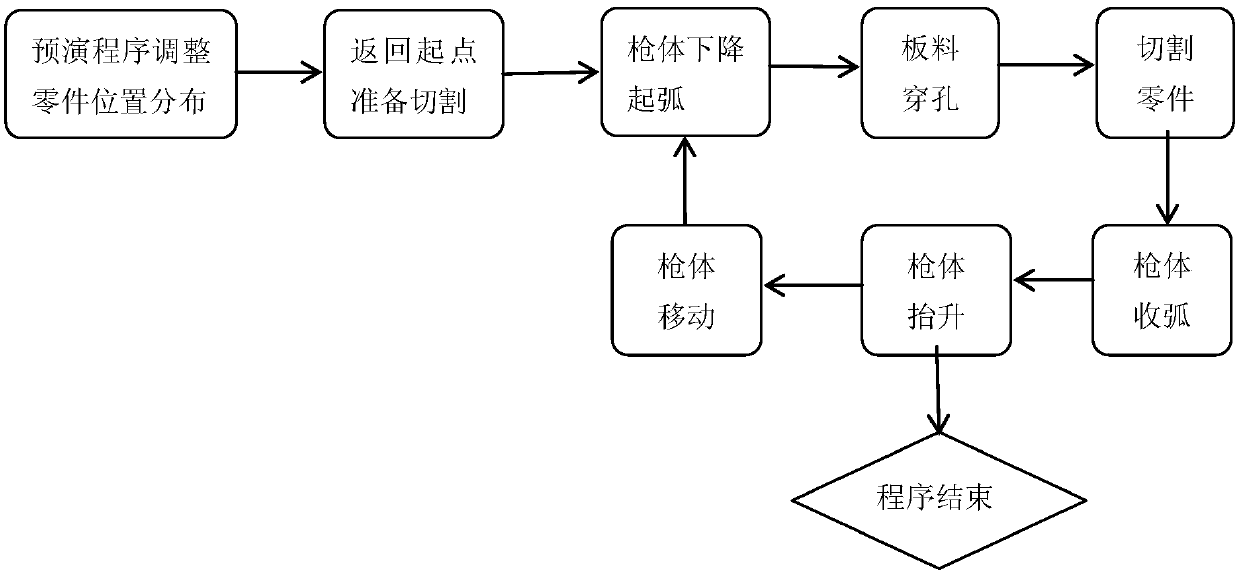

[0034] see Figure 8 , Figure 11 with Figure 12 , a numerical control plasma programming method for realizing continuous cutting, comprising the following steps:

[0035] 1) Export a cutting program text in the programming steps of FAST programming software, and record the number of parts to be cut and the margins between adjacent parts at the same time;

[0036] 2) draw graphics according to the cutting program text, the number of parts and the margin between adjacent parts in step 1);

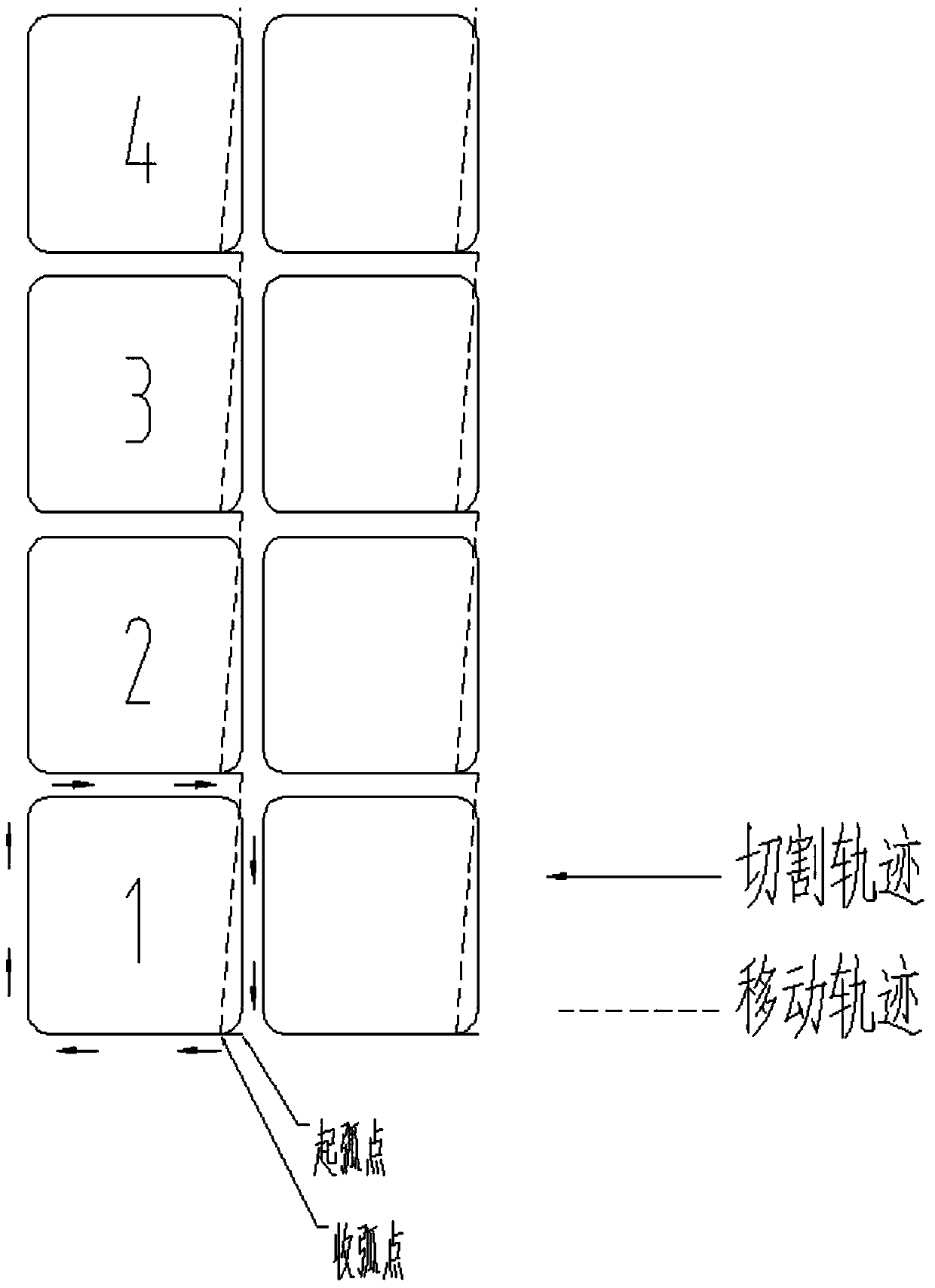

[0037] 3) In the figure drawn in step 2), make a straight line with the arc starting point and arc ending point of the adjacent parts as the end points, and this straight line is the continuous cutting path;

[0038] 4) Convert the continuous cutting path in step 3) into a text form and add it to the cutting program text.

[0039] In above-mentioned step 2)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com