An electric drum permanent magnet motor

A technology of permanent magnet motor and electric drum, which is applied in the direction of magnetic circuit rotating parts, magnetic circuit static parts, magnetic circuit shape/style/structure, etc. problem, to achieve the effect of small positioning force and moment of inertia, light weight of the motor, and large magnetic conduction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

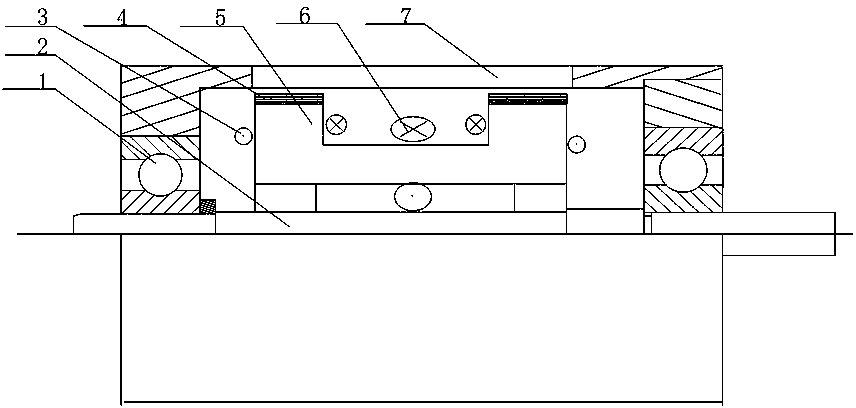

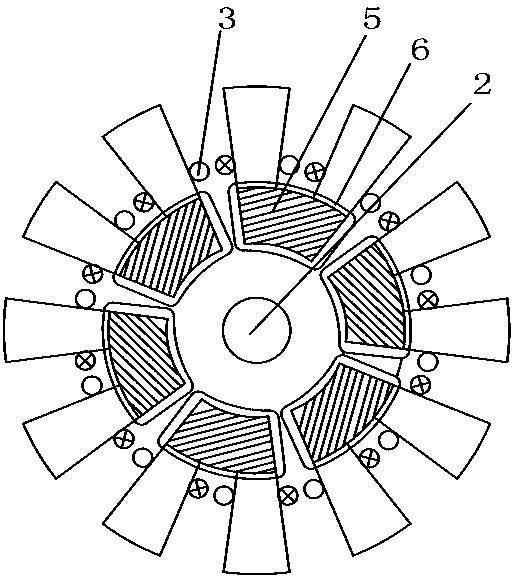

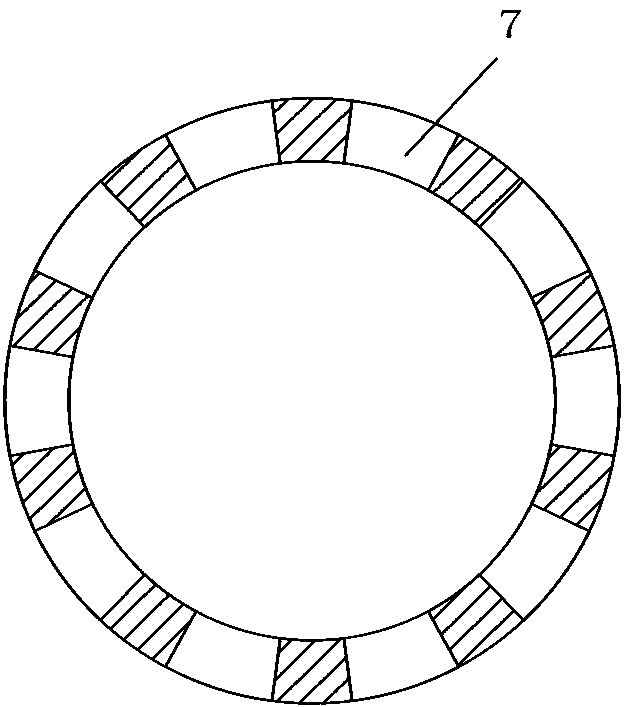

[0025] figure 1 It is a vertical sectional view of an electric drum permanent magnet motor in the technology of the present invention when the flux linkage is minimum. Among them, 1 bearing, 2 shafts, 3 armature windings, 4 permanent magnets, 5 stator cores, 6 field windings, and 7 rollers.

[0026] An electric drum permanent magnet motor, characterized in that: the drum is mounted on the shaft through bearings and can rotate around the shaft, 5K rectangular holes are evenly distributed on the circumferential surface of the drum, K is a positive integer, where k=2, the rectangular hole is viewed from the side The holes are fan-shaped.

[0027] The stator core is fixed in the middle of the shaft. The stator core is composed of 3K evenly distributed "匚"-shaped stator cores. The yoke in the middle of the stator cores is parallel to the axis; each stator core has two stator teeth at both ends. The side surfaces of the stator teeth are fan-shaped; all the stator teeth face to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com