Adhesive tape, heat-dissipating sheet, electronic apparatus, and method of manufacturing adhesive tape

A technology of electronic equipment and adhesive tape, which is applied in the construction parts of electrical equipment, chemical instruments and methods, cooling/ventilation/heating transformation, etc., which can solve the problems of reduced heat dissipation, inability to maintain adhesive force, and poor appearance. Achieve excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0178] "PET25×1J0L" (manufactured by Nippa Co., Ltd., a release liner with a silicone-based release-treated surface on the surface of a PET film with a smooth surface) was coated with the above-mentioned adhesive a using a roll coater, and then dried at 100°C. It was dried for 1 minute to prepare an adhesive layer with a thickness of 1 μm.

[0179] Next, the above-mentioned pressure-sensitive adhesive layer was transferred to one surface of "K100-2.0W" (manufactured by Mitsubishi Plastics Corporation, polyester film, thickness 2 μm) as a support to obtain a single-sided adhesive tape.

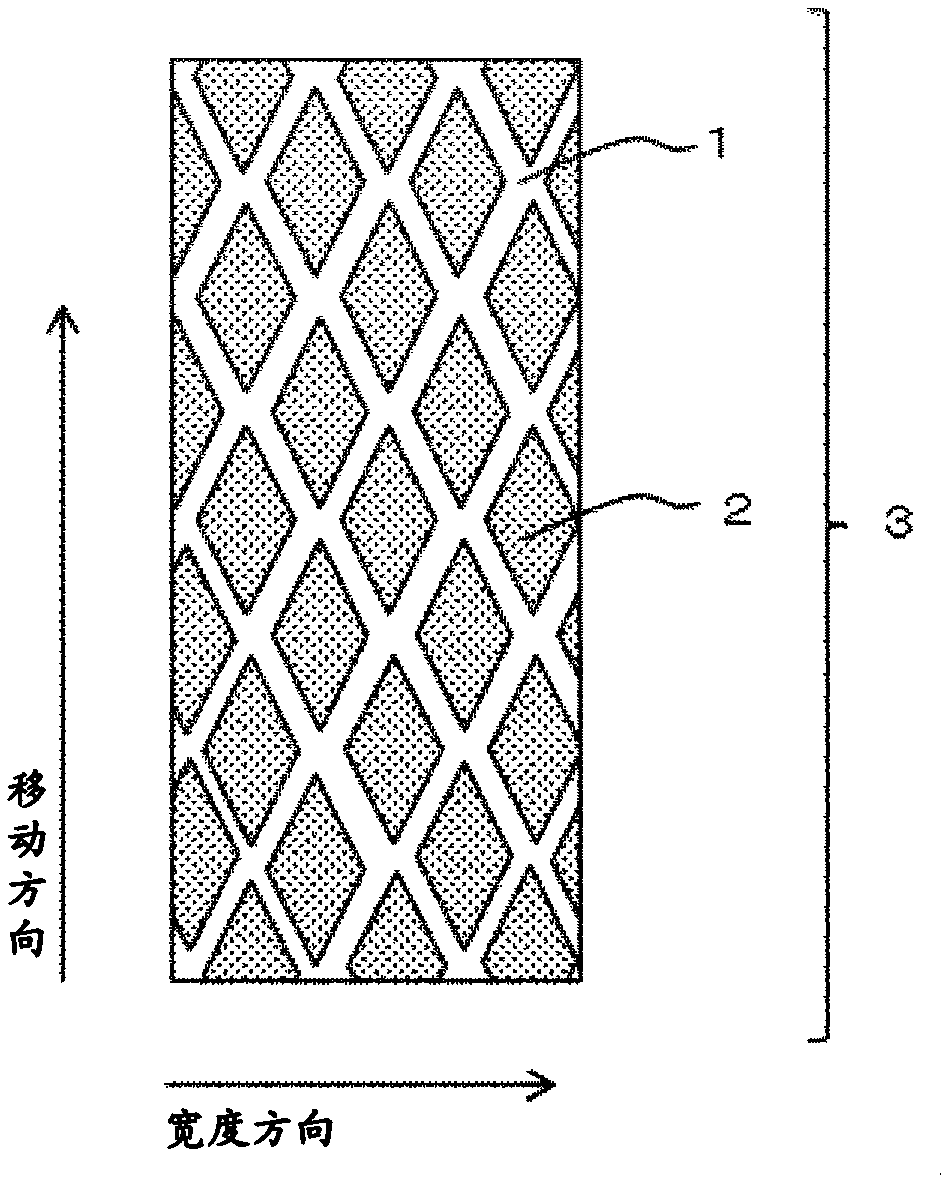

[0180] Next, using a gravure coater, the above-mentioned adhesive a was dot-printed on the other side of the above-mentioned support constituting the above-mentioned single-sided adhesive tape, and dried at 100° C. for 1 minute to obtain a figure 1 The shown adhesive tape is an adhesive tape having a total thickness of 6 μm of the substantially diamond-shaped 3 μm-thick adhesive portion. It sh...

Embodiment 2~12

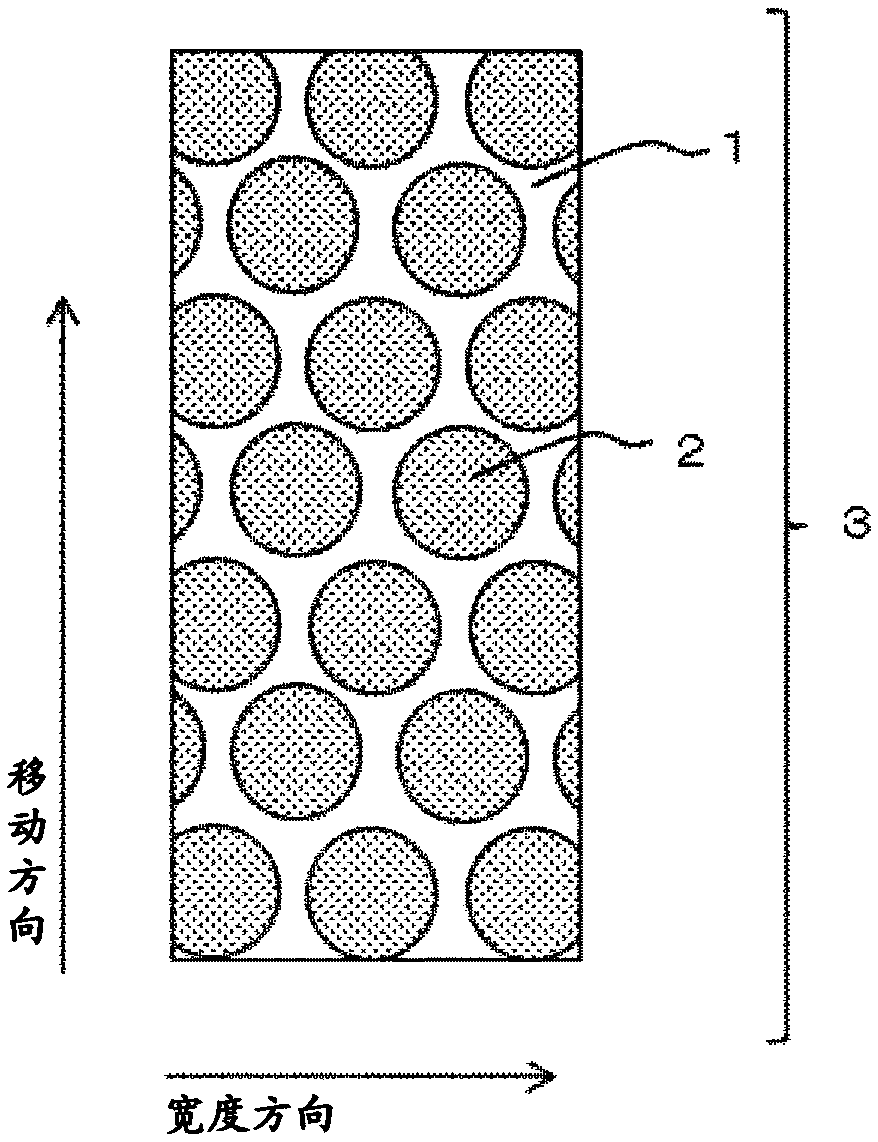

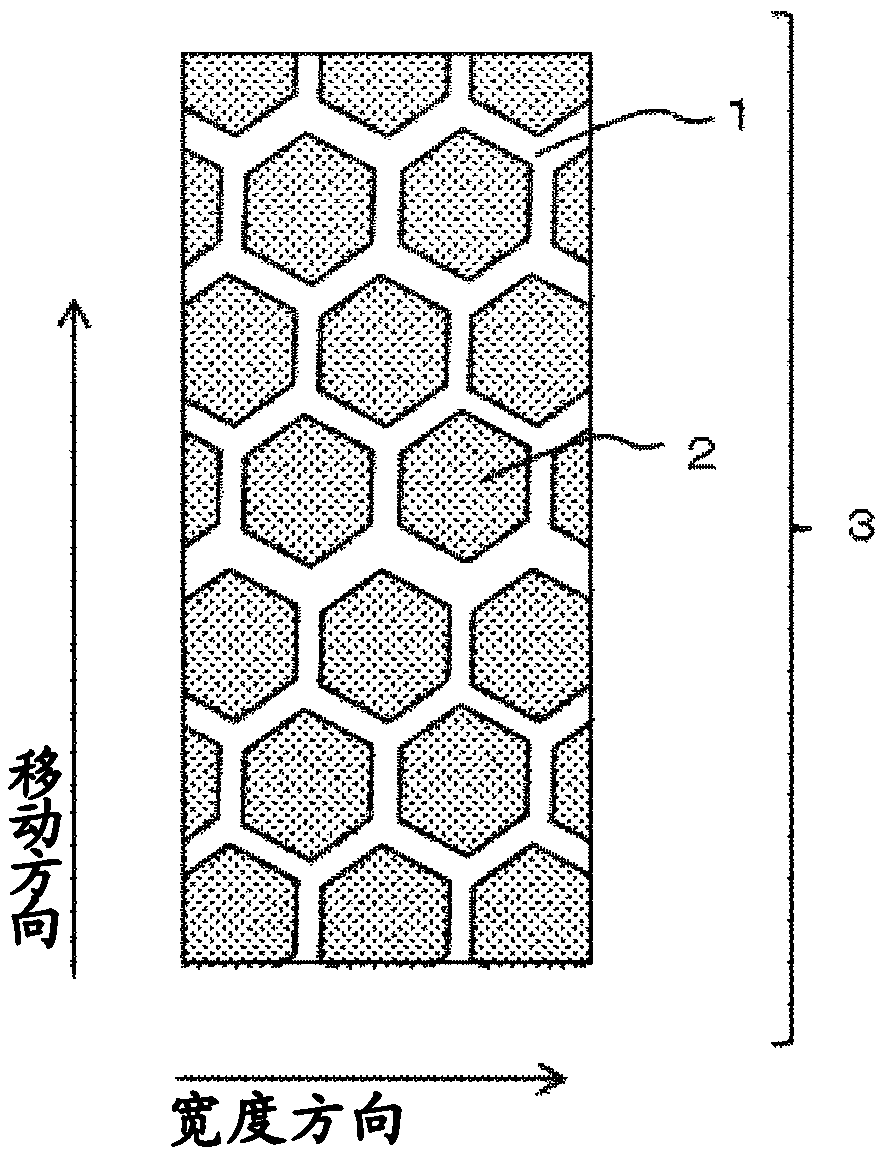

[0183] The adhesive tape was produced by the method similar to Example 1 except having changed the shape, area, and the thickness of the adhesion part (B) into Tables 1-3.

Embodiment 13

[0185] Using a gravure coater, the above-mentioned adhesive a was dot-printed on "PET25×1J0L" (manufactured by Nippa Co., Ltd., a release liner having a silicone-based release-treated surface on the surface of a PET film with a smooth surface) at 100 °C and let it dry for 1 minute, thus forming figure 1 An adhesive portion having a thickness of 3 μm is shown in a substantially rhombic shape (the angle of the corner portion toward the moving direction of the adhesive tape is 60°). It should be noted that, among the above-mentioned adhesive parts, the distance between any adhesive part and the adjacent adhesive part is 0.1 mm.

[0186] Next, the above-mentioned adhesive part was transferred to one side of "K100-2.0W" (Mitsubishi Plastics Co., Ltd. product, polyester film, thickness 2 micrometers) as a support body, and the single-sided adhesive tape was obtained.

[0187] Next, using a gravure coater, the above-mentioned adhesive a is dot-printed on the other side of the suppor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com