Composite material with eucalyptus biochar loaded with nano zero-valent iron and preparation method of composite material

A nano-zero-valent iron and composite material technology, which is applied in chemical instruments and methods, water pollutants, other chemical processes, etc. Problems such as the limited number of loads to achieve the effect of improving the removal capacity, enhancing the reactivity, and evenly dispersing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

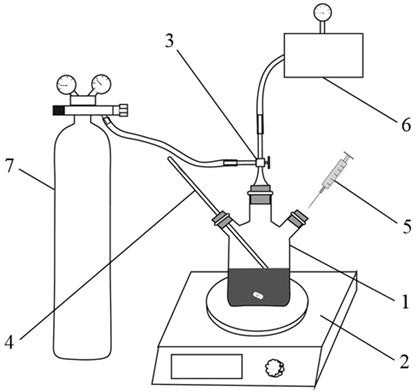

Method used

Image

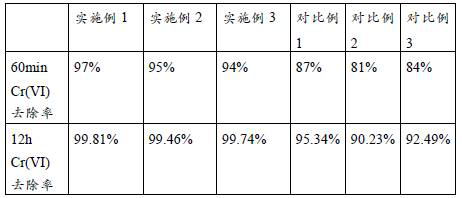

Examples

Embodiment 1

[0055] A) Preparation of eucalyptus biochar. Screen the eucalyptus wood chips through a 10-mesh sieve to remove impurities and ensure that their particle sizes are as uniform as possible, and dry them in an oven at 50°C for 8 hours. Then put it into a tube furnace, raise the temperature to 500°C at a rate of 10°C / min in an environment with a nitrogen flow rate of 100ml / min, and keep the temperature for 2 hours to carbonize eucalyptus wood chips or eucalyptus leaves. During this period, try to maintain the heat distribution inside the furnace body and carbonized evenly, take out the material after cooling, dry at 105°C for 12 hours, and package for later use.

[0056] B) Preparation of extract solution. The eucalyptus leaves were cut from the branches, rinsed with tap water to remove dirt and impurities, then rinsed with deionized water, dried naturally and cut into small pieces with scissors, each with a size of 1.2×1.2 cm. Weigh 15 g of eucalyptus leaves into 250 ml of deio...

Embodiment 2

[0062] On the basis of Example 1, Example 2 adjusts the following parameters.

[0063] A) Screen through a 20-mesh sieve, and dry in an oven at 60°C for 9 hours. In an environment with a nitrogen flow rate of 100ml / min, the temperature was raised to 520°C at a rate of 12°C / min, and the temperature was maintained for 2.5 hours for carbonization. After drying at 110°C for 15 hours, it was packaged for use.

[0064] B) The flakes are all 1.5×1.5cm in size. Weigh 20g of eucalyptus leaves into 250ml of deionized water, heat in a water bath at 85°C for 65min, cool and filter to obtain the extract.

[0065] C) Mix 1.5g eucalyptus biochar and 50ml extract in a three-neck flask, and ultrasonicate it for 25min. The ultrasonic frequency is 40KHz, the power is adjusted to 250W, and the ultrasonic modification temperature is controlled at 20°C.

[0066] D) Gradually heat the temperature to 60°C during the process of feeding nitrogen gas. After 3 minutes of nitrogen gas feeding, 214ml fer...

Embodiment 3

[0069] On the basis of Example 1, Example 2 adjusts the following parameters.

[0070] A) Dry in an oven at 40°C for 7 hours. In an environment with a nitrogen flow rate of 100ml / min, the temperature was raised to 480°C at a rate of 8°C / min, and the temperature was maintained for 2 hours for carbonization. After drying at 100°C for 10 hours, it was packaged for use.

[0071] B) Weigh 10 g of eucalyptus leaves into 250 ml of deionized water, heat in a water bath at 80° C. for 55 min, cool and filter to obtain an extract.

[0072] C) Take 1g of eucalyptus biochar and 70ml of extract solution and mix them in a three-neck flask, and then ultrasonicate it for 10min. The ultrasonic frequency is 20KHz, the power is adjusted to 100W, and the ultrasonic modification temperature is controlled at 20°C.

[0073] D) Gradually heat the temperature to 40°C during the process of feeding nitrogen gas. After feeding nitrogen gas for 3 minutes, slowly add 90ml of ferrous chloride with a concen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com