Manufacturing apparatus for flexible electronics

A technology for flexible substrates and separation equipment, applied in the fields of final product manufacturing, sustainable manufacturing/processing, semiconductor/solid-state device manufacturing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

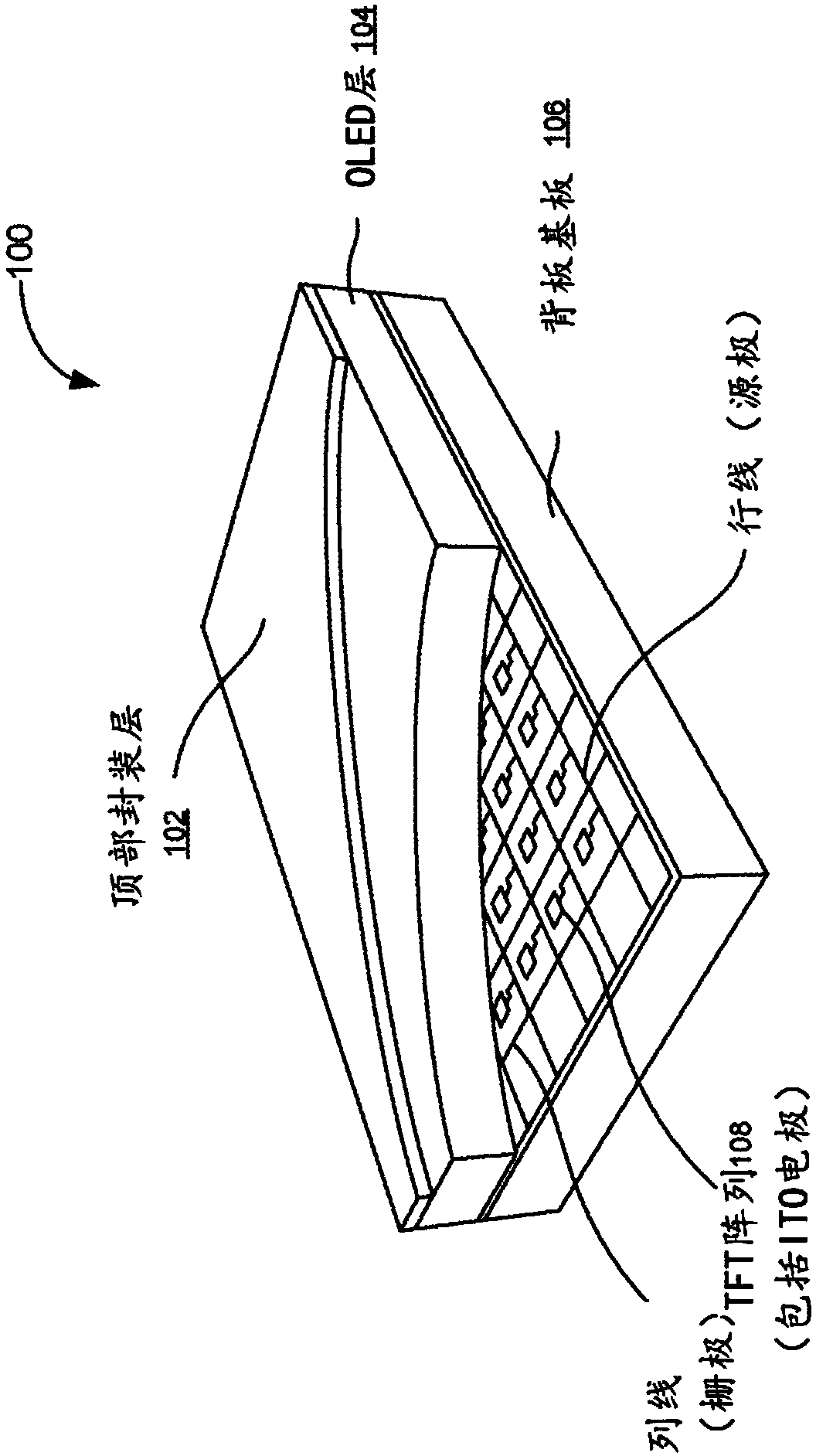

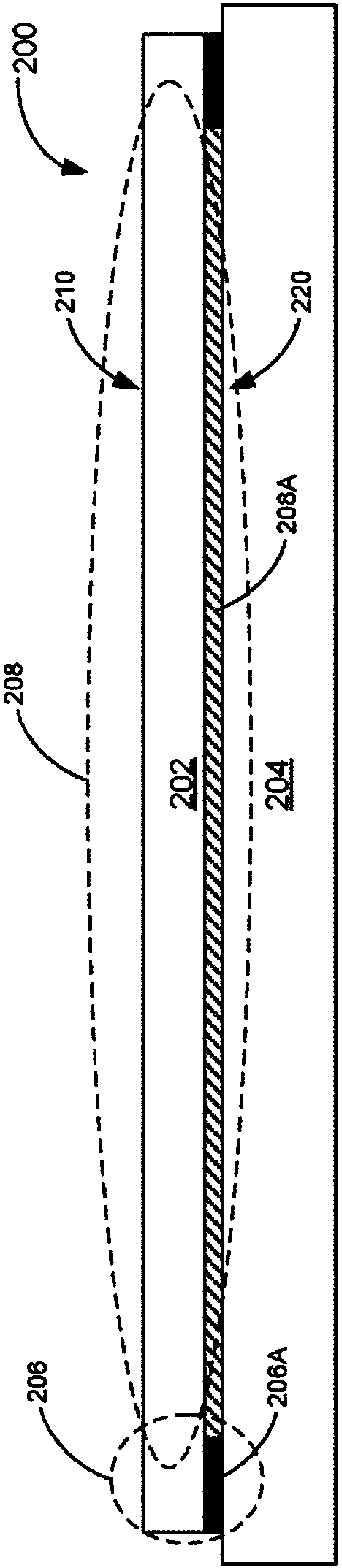

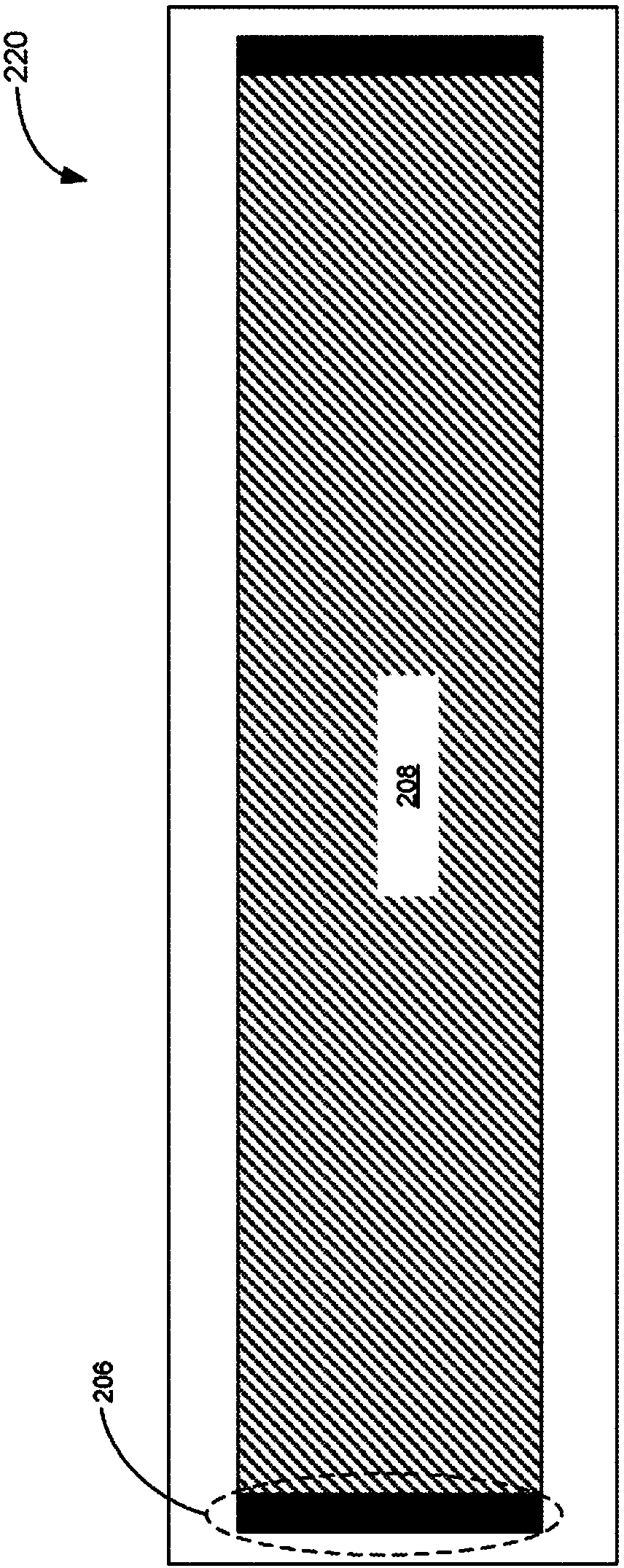

[0024] According to various embodiments of the present application, the flexible substrate adheres to the rigid carrier sufficiently firmly so that thin film transistor (TFT) devices and corresponding display devices can be fabricated on the flexible substrate when the flexible substrate is supported by the rigid carrier. After forming the TFT devices and corresponding display devices, the flexible substrate needs to be separated from the rigid carrier without causing any damage to the TFT devices and corresponding display devices formed thereon. According to various embodiments of the present application, the separation device is designed to facilitate separation of the flexible substrate. The separation device operates based on vacuum adsorption; it consists of panels, rods and rod shafts. The panel is used for vacuum suction, and includes a plurality of vacuum suction holes located on the bottom surface of the panel and distributed across the bottom surface. A rod is mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com