Stator with insulated bar windings for electric motors

An electrical insulation and stator technology, applied in the shape/pattern/structure of winding insulation, the shape/pattern/structure of winding conductors, electric components, etc., can solve the problem of cost of insulating paper, and ensure deformability and heat conduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The exemplary embodiments explained below are preferred embodiments of the present invention. In an exemplary embodiment, the described components of an embodiment each represent a separate feature of the invention, which features are to be considered independently of each other and each also develop the invention independently of each other, and thus may also be used alone or in addition to all Combinations other than those shown are considered components of the present invention. Furthermore, other features of the invention which have been described may also be added to the described embodiments.

[0033] In the figures, functionally identical elements are correspondingly provided with the same reference symbols.

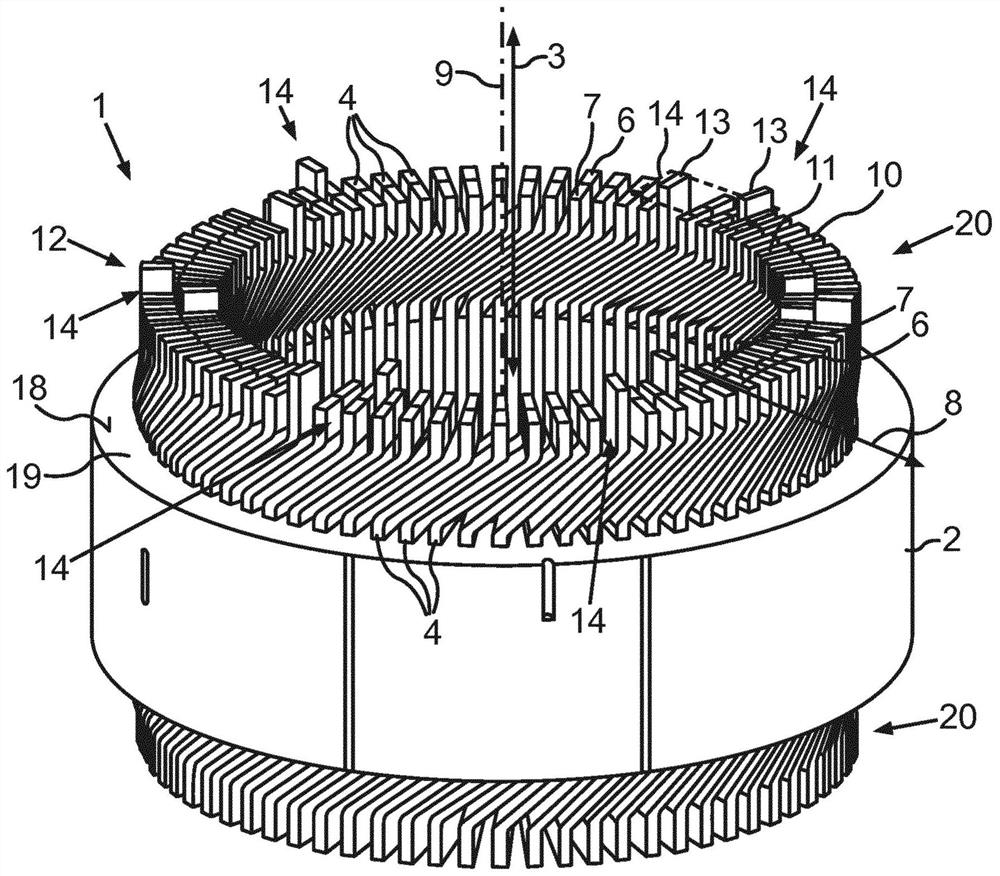

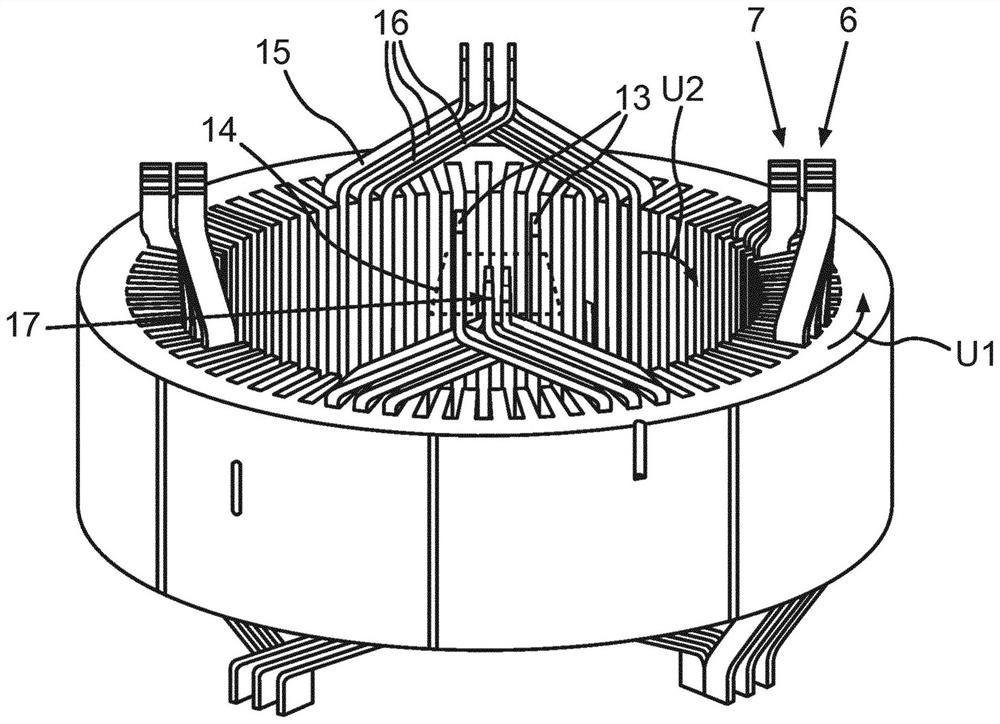

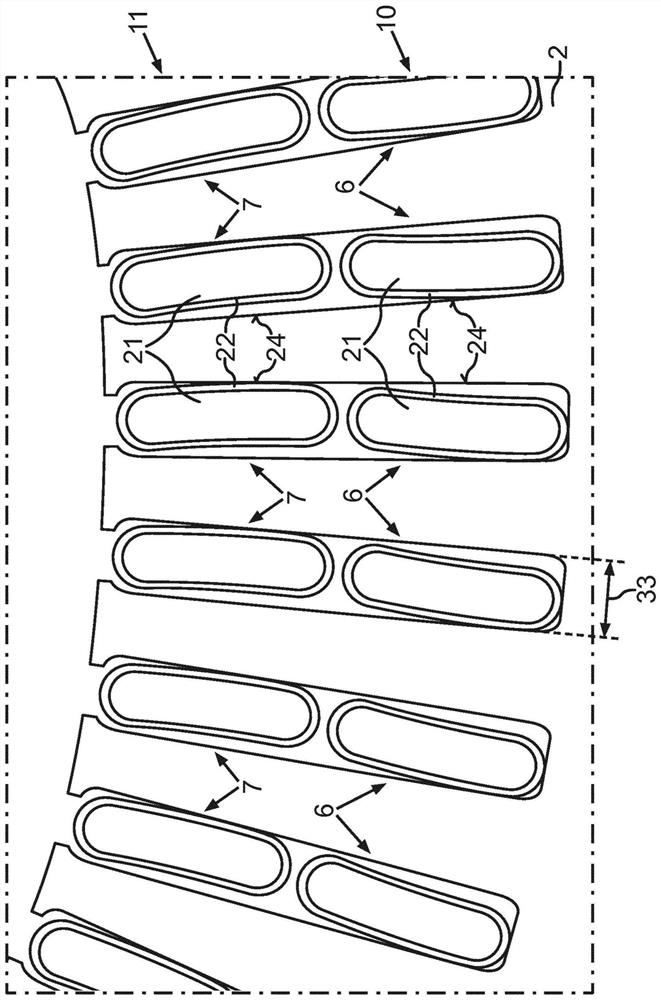

[0034] figure 1 A stator 1 for an electric machine is shown. The stator 1 may be provided eg for a starter generator of a motor vehicle. The stator 1 has a laminated core 2 which can be formed in a manner known per se from soft-magnetic metal sheets (co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com