Circumferential multi-station bolt automatic assembling system and control method thereof

An automatic assembly and multi-station technology, applied in the direction of metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of high labor intensity, high production cost, low operating efficiency, etc., to reduce operating hours, improve assembly quality and The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the objectives, technical solutions and advantages of the present invention clearer, the following further describes the present invention in detail with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

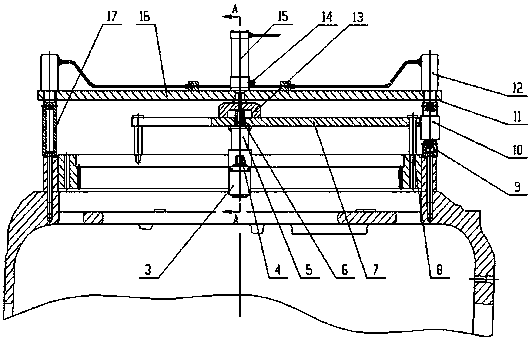

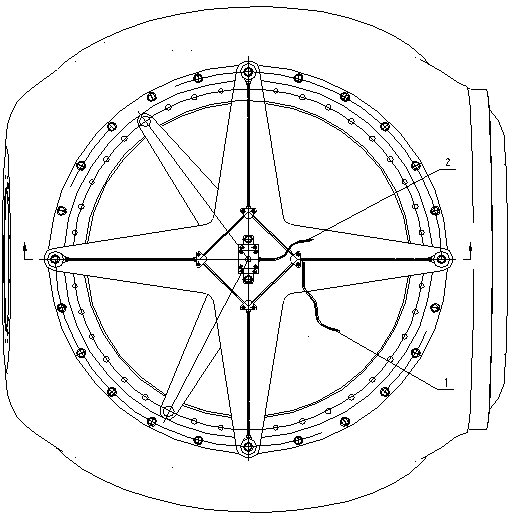

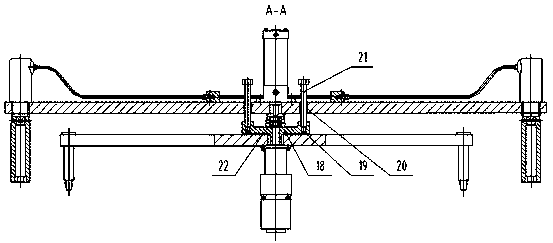

[0032] Combine Figure 1-Figure 6 : A circumferential multi-station bolt automatic assembly system, including pneumatic control system and electrical control system,

[0033] The pneumatic control system includes a cylinder 15, a cylinder intake pipe 2, a pneumatic torque wrench intake pipe 1, a pneumatic torque wrench 12, a muffler 14, a fixing bracket 7, a positioning pin 8, a short drive sleeve 9, and an elastic retaining ring for the shaft 11. Type bracket 13, rotary bracket 16, long drive sleeve 17, T-shaped drive arm 18, elastic cylindrical pin Ⅰ19, guide sleeve 20, guide column 21 and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com