Coating impact fatigue test device

A technology of impact fatigue and experimental equipment, applied in the direction of measuring equipment, instruments, scientific instruments, etc., can solve the problems of inconvenient operation, difficulty in achieving high-energy impact, and difficulty in impacting to the same position, so as to avoid secondary impact, Ease of use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with specific drawings.

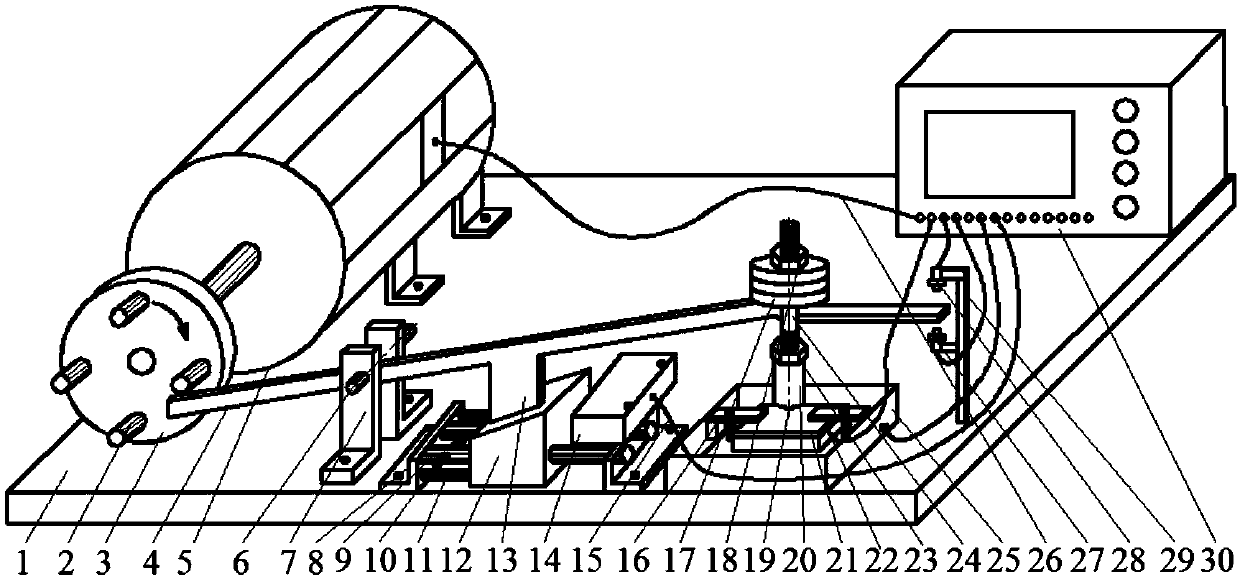

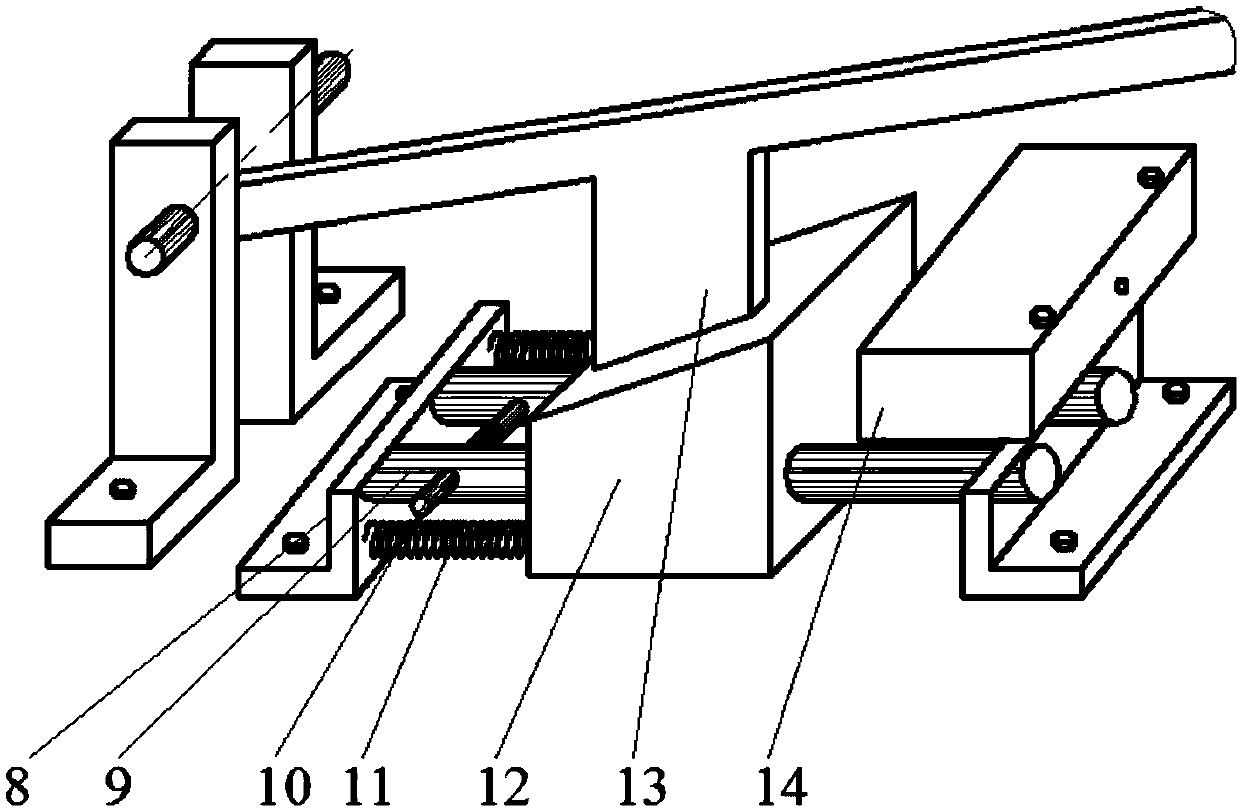

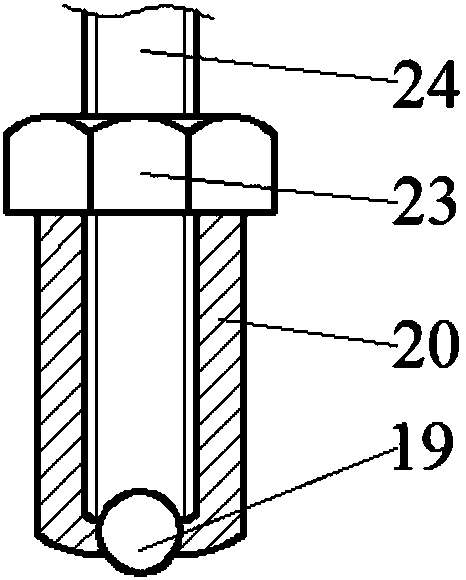

[0025] Such as Figure 1-Figure 3 As shown, the coating impact fatigue test device of the present invention comprises a base 1, a rotating shaft support 7 is installed on the base 1, a rotating shaft 6 on the rotating shaft support 7 supports a lever 4, and a speed regulating motor 5 is installed on the base 1 at the left end of the lever 4, The power output shaft of the speed-regulating motor 5 is connected to the turntable 3, and four shift forks 2 are arranged on the turntable 3 along the circumferential direction. During the rotation of the turntable 3, the four shift forks 2 can sequentially press down the left end of the lever for a certain distance, and then connect with the lever. Disengaged, so that the right end of the lever rises and falls freely, thereby realizing the repeated impact of the hard alloy ball fixed under the right end of the lever on the coating sampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com