Multi-layer circuit board installing structure with vibration resistance

A multi-layer circuit board and installation structure technology, applied in the direction of support structure installation, clamping/extracting device, etc., can solve the problems of easy fracture, vibration stress concentration, complex structure, etc., achieve good processability, improve life and reliability The effect of sex and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

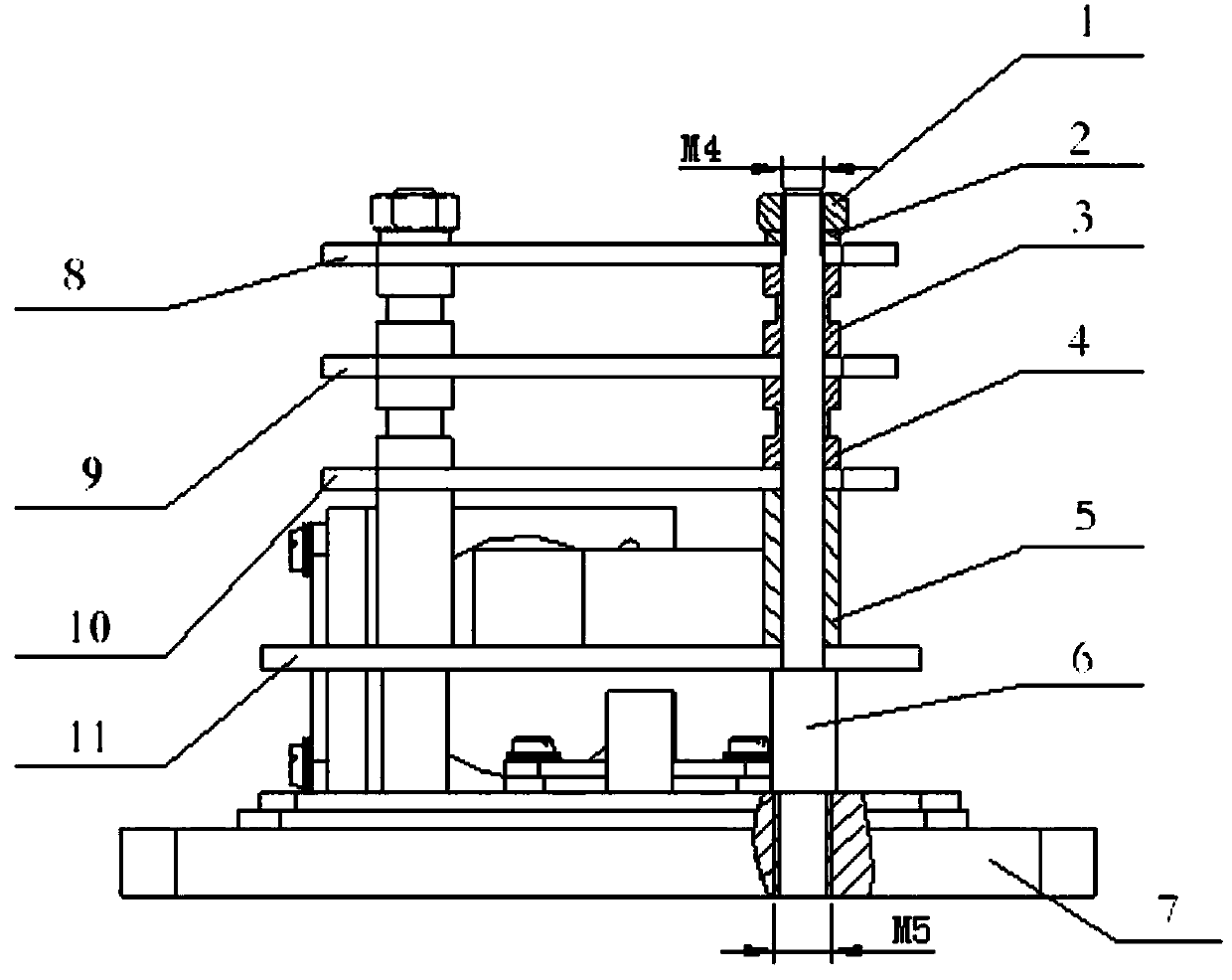

[0013] The present invention will be described in further detail below. refer to figure 1 . An anti-vibration structure that ensures that the acceleration sensor is resistant to random vibrations. The structure is composed of a base 7, a pillar 6, a sleeve Ⅰ5, a sleeve Ⅱ4, a sleeve Ш3, a spring washer 2, a nut 1 and a multilayer circuit board assembly. The layer circuit board assembly includes a first layer circuit board 11, a second layer circuit board 10, a third layer circuit board 9 and a fourth layer circuit board 8. The pillar 6 is an integral design, and the lower end is screwed on the base 7. A layer of circuit board 11 is placed on the journal of the pillar 6. On the first layer of circuit board 11, the sleeve I5 is inserted into the pillar 6, and the second layer of circuit board 10 passes through the pillar 6 and is pressed on the sleeve I5. ; On the second-layer circuit board 10, the sleeve II4 is inserted into the pillar 6; the third-layer circuit board 9 passes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com