Cantilever crane provided with two suspension trolleys and capable of being rotated at any angle

A technology of suspending a trolley at any angle. It is applied in the directions of traveling bridge cranes, cranes, and traveling mechanisms. It can solve the problems of waste of manpower and material resources, inconvenience, and the inability to directly hand over goods in the next workshop, and achieve the effect of improving efficiency and supporting convenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

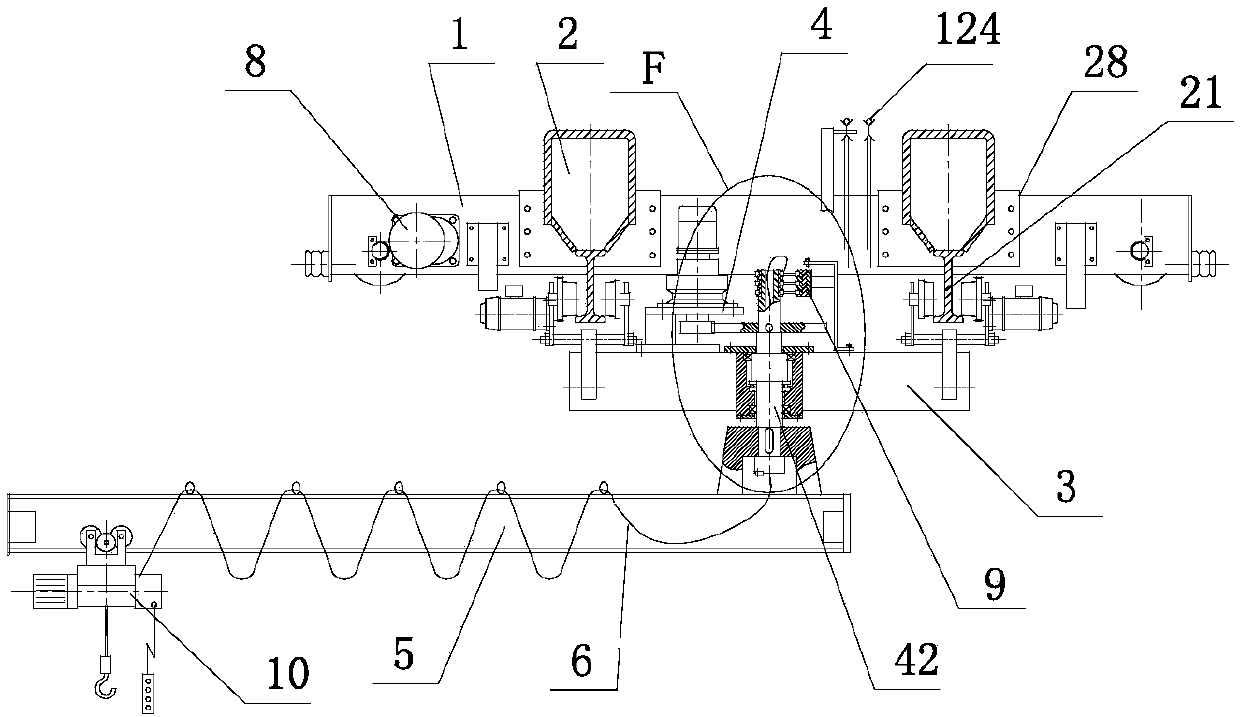

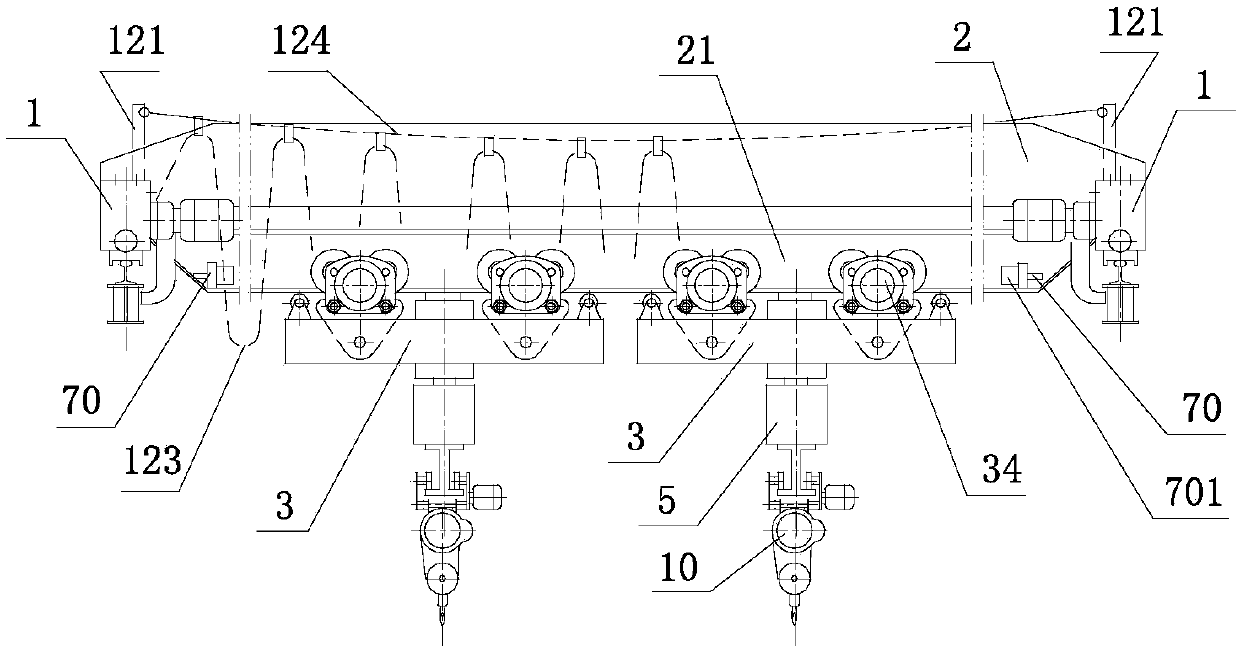

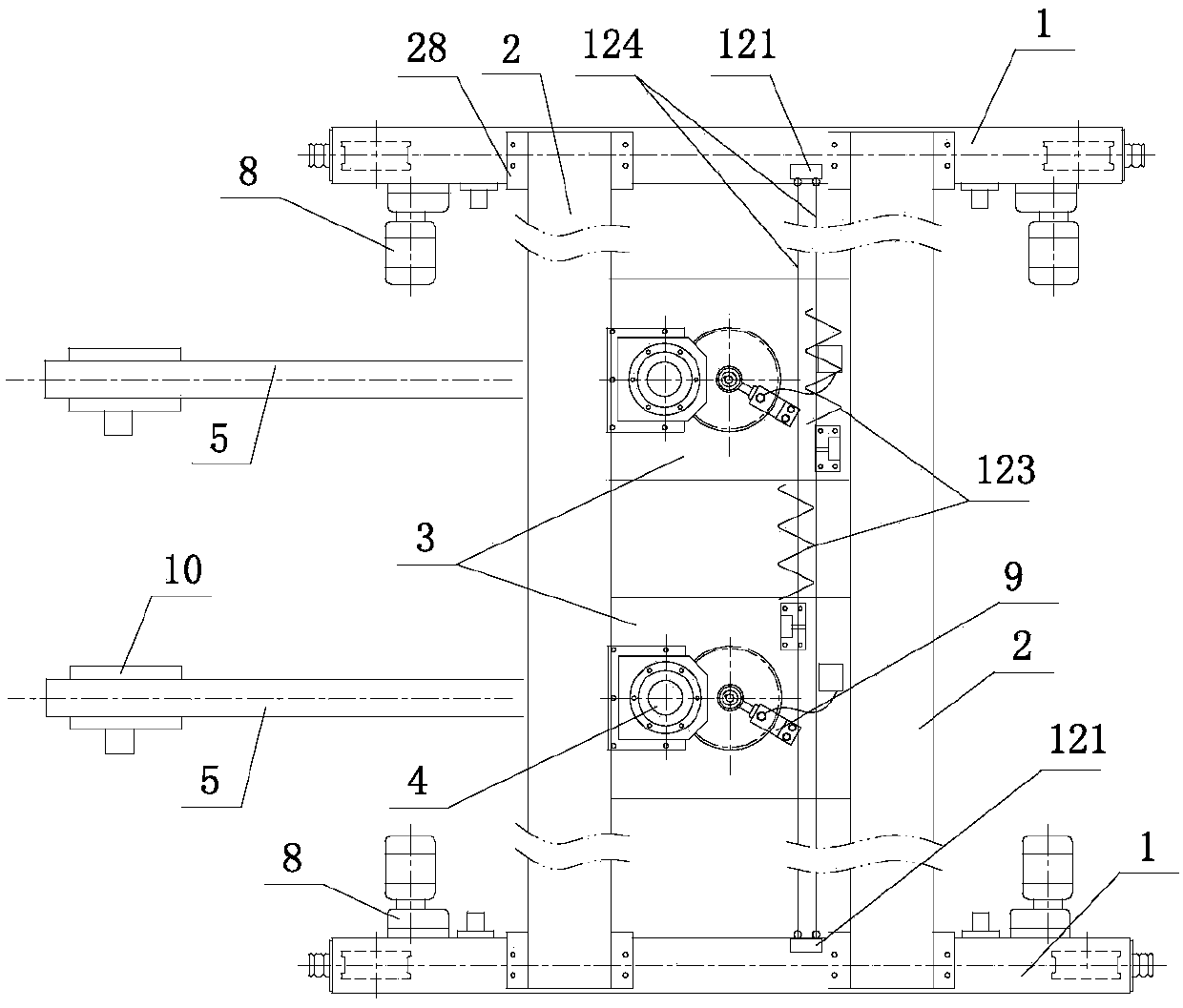

[0032] Such as figure 1 , figure 2 , image 3 As shown, a cantilever crane with two suspension trolleys that can rotate at any angle includes a double-girder bridge frame 28; the double-girder bridge frame includes an end beam 1 and a main beam 2; a track 21 is provided below the main beam 2; The track is made of I-shaped steel or H-shaped steel; the two ends of the track are welded with a car block 70, and the buffer 701 is connected to the car block; two suspension trolleys 3 are connected between the two rails 21; the suspension The trolley is provided with a rotating mechanism 4; the boom shaft 42 in the rotating mechanism is a hollow shaft, the lower end of which is connected to the cantilever member 5, and the upper end is connected to the collector slip ring 9; an electric hoist 10 is installed on the cantilever member 5, and the The hoist can move horizontally along the cantilever beam; the cantilever beam is located under the main beam and can be stretched out of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com