Elongated material weighing system

A weighing system and material technology, which is applied in the direction of weighing equipment, weighing, and measuring devices for materials with special properties/forms, and can solve the problems of difficult product quality assurance, damage to weighing devices, and low weighing efficiency, etc. problem, to achieve the effect of increasing the number of weighing, increasing the weighing speed and improving the weighing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

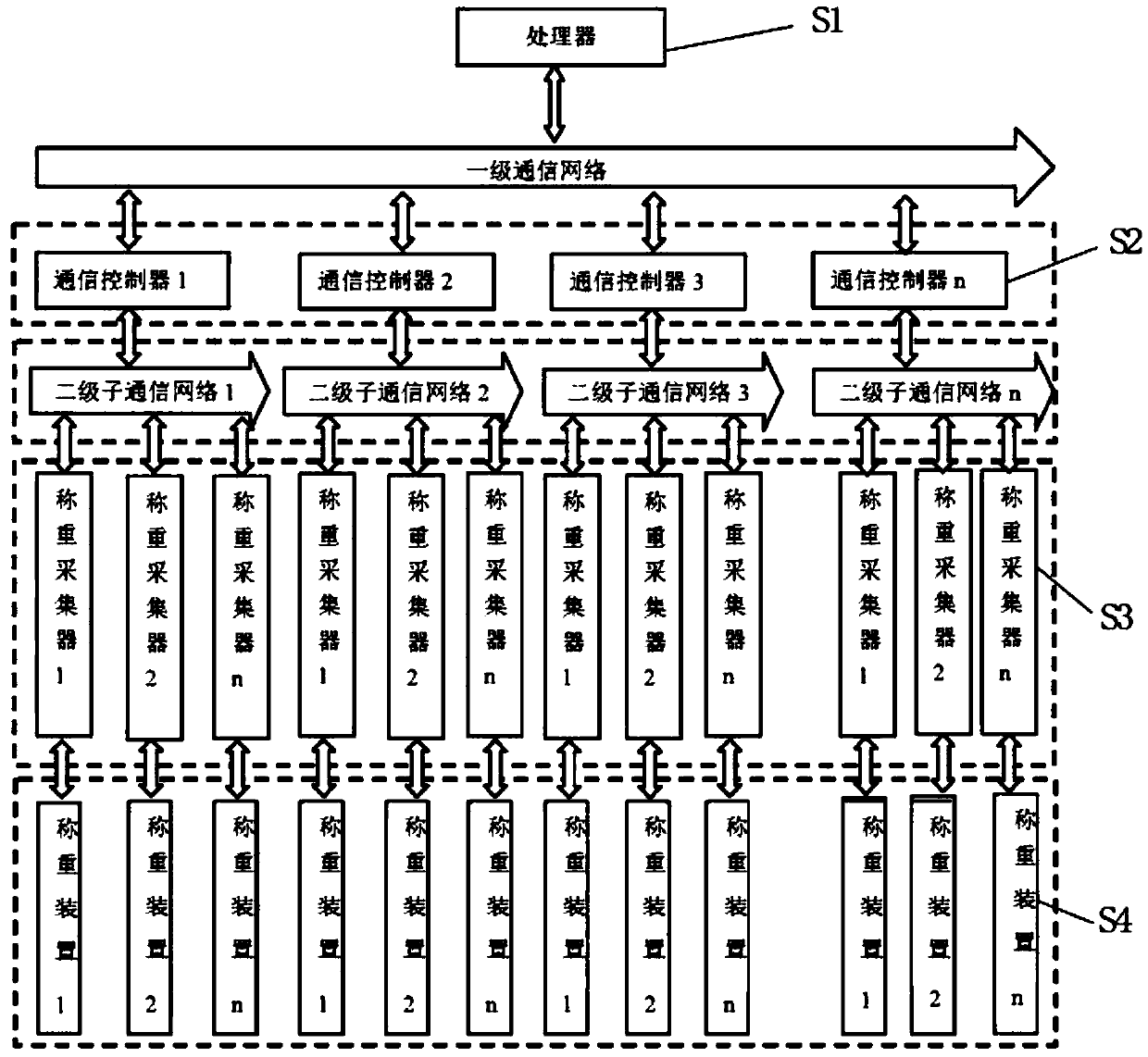

[0037] Such as figure 1 , the weighing system is composed of a processor S1, multiple weighing devices S4, multiple communication controllers S2 and multiple weighing collectors S3. The weighing device S4 is used to collect weighing signals and upload them to the processor S1. The weight collector S3 is used for analog-to-digital conversion of the weighing signal, and it corresponds to the weighing device S4 one by one. The input end of each weighing collector S3 is electrically connected to the output end of the corresponding weighing device S4 to obtain The weighing signal of the weighing device S4, and each weighing collector S3 is equipped with a metal cover to shield external interference. The advantage of this is that a single weighing collector S3 only processes the weighing signal of a single weighing device S4 , so as to avoid the problem of electromagnetic interference between channels when a single weighing collector S3 processes multiple weighing signals, and it is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com