Mini optical fiber Fabry-Perot pressure sensor

A pressure sensor, fiber optic technology, applied in the application of optical methods for fluid pressure measurement, fluid pressure measurement, instruments, etc., can solve the application difficulties, the difficulty of manufacturing Brie-Perot fiber optic sensors, and the bending degree of the diaphragm is easy to exceed. Its deflection and other problems, to achieve the effect of wide adaptability, precise measurement accuracy, small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

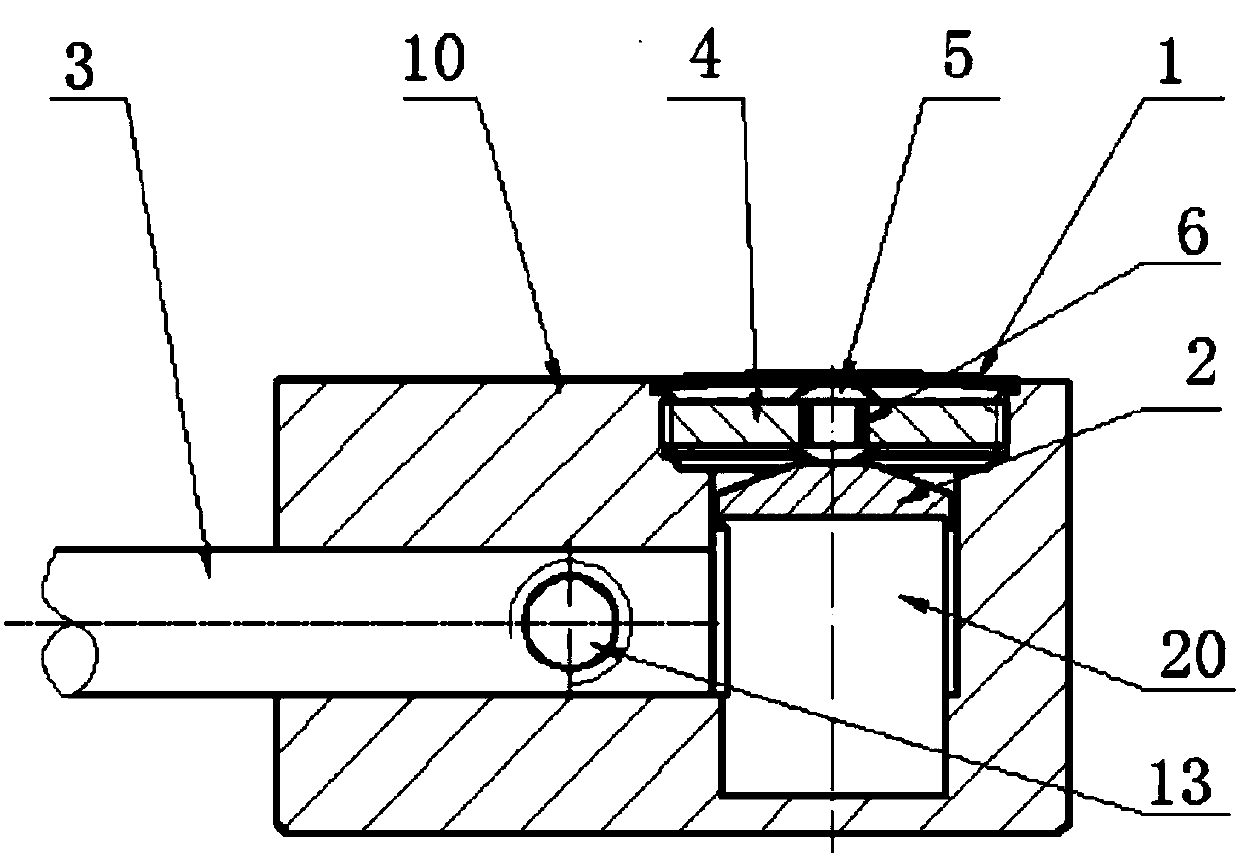

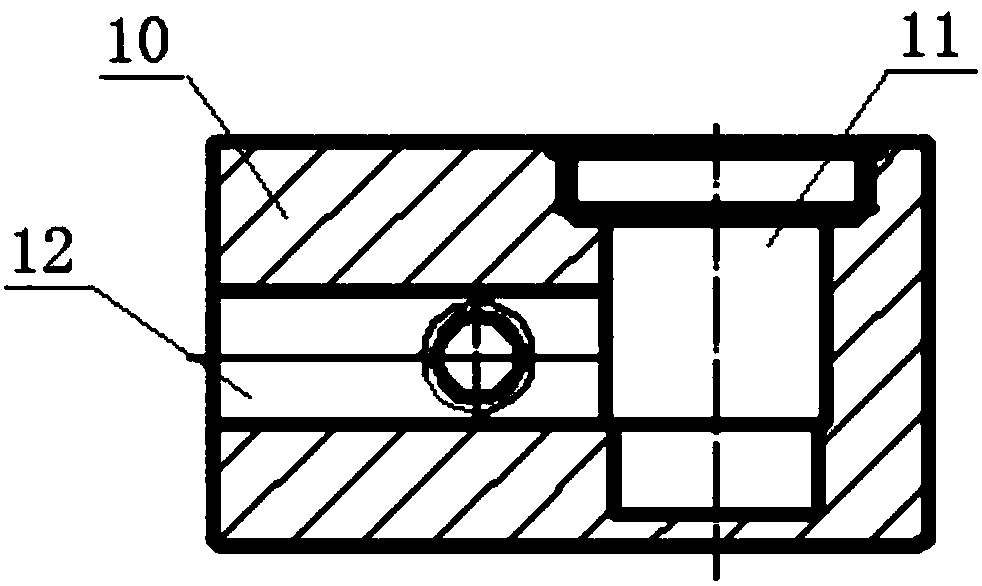

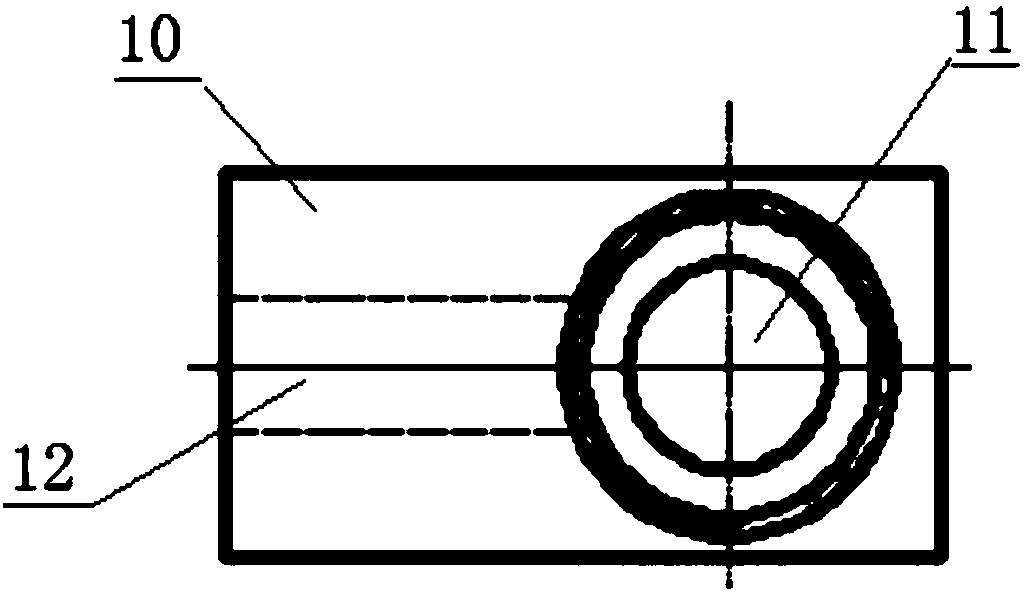

[0035] see Figure 1 to Figure 5 , the miniature optical fiber Fabry pressure sensor, its sensor seat is a cube sensor seat 10, and the described axial force member is a cylindrical force-sensitive crystal 20; one end of the cube sensor seat 10 is provided There is a vertical stepped counterbore 11, all straight small elongated holes 12 in the middle of the other end of the cube sensor seat 10, and the small elongated hole communicates with the middle part of the stepped counterbore 11; The lower end of the sensitive crystal 20 is connected with the lower hole of the stepped counterbore 11, and the upper end is close to the mouth of the middle hole of the stepped counterbore 11; fixed, one end of the optical fiber 3 is perpendicular to the side 21 of the force-sensitive crystal 20, and an optical fiber Fab cavity is formed between the end face of the optical fiber and the side 21 of the force-sensitive crystal.

[0036] The miniature fiber optic Fabry pressure sensor also inc...

Embodiment 2

[0043] , see Image 6 and Figure 7 , the miniature optical fiber Fabry pressure sensor, the sensor seat is an annular sensor seat 30, the middle of which is provided with an elongated hole 31; the axial force member is a force cylinder 40, one side of which is provided with a The smooth plane 41 and the upper and lower ends are provided with flanges 42 as a positioning stop; the annular sensor seat 30 is set on the outside of the stressed cylinder 40, and the optical fiber 3 is arranged in the elongated hole 31 and Fixed by the set screw 13 , an optical fiber Fab cavity is formed between the end surface of the optical fiber 3 and the plane 41 on the annular sensor seat 30 .

[0044] The miniature fiber optic Fabry pressure sensor also includes:

[0045] Two positioning rings 8 are respectively embedded between the upper and lower ends of the stressed cylinder 40 and the annular sensor seat 30;

[0046] Two rubber sealing rings 9 are respectively set on the positions close ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com