Continuous vacuum defoaming device

A technology of vacuum defoaming and feed inlet, which is applied in the direction of liquid degassing, foam dispersion/prevention, chemical instruments and methods, etc., and can solve problems such as efficiency and quality that need to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

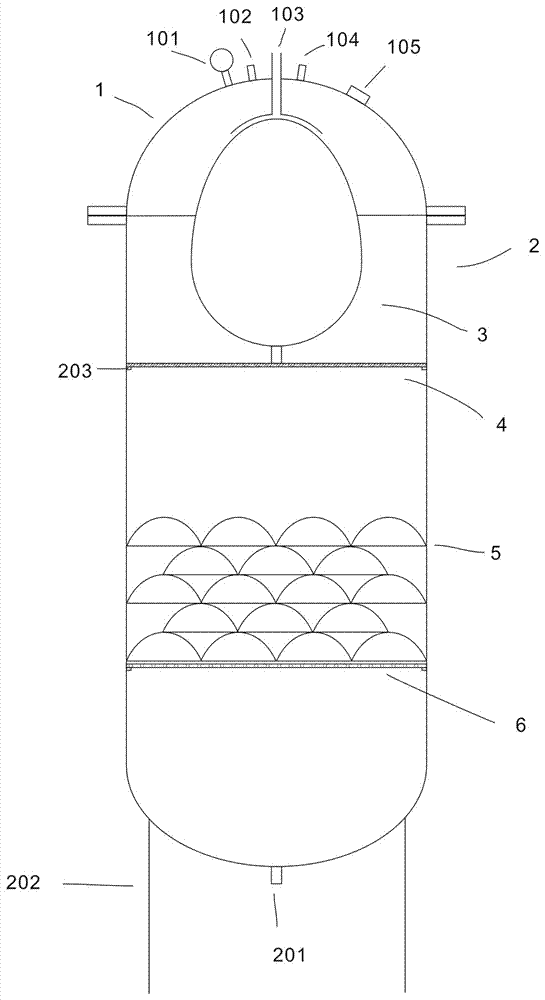

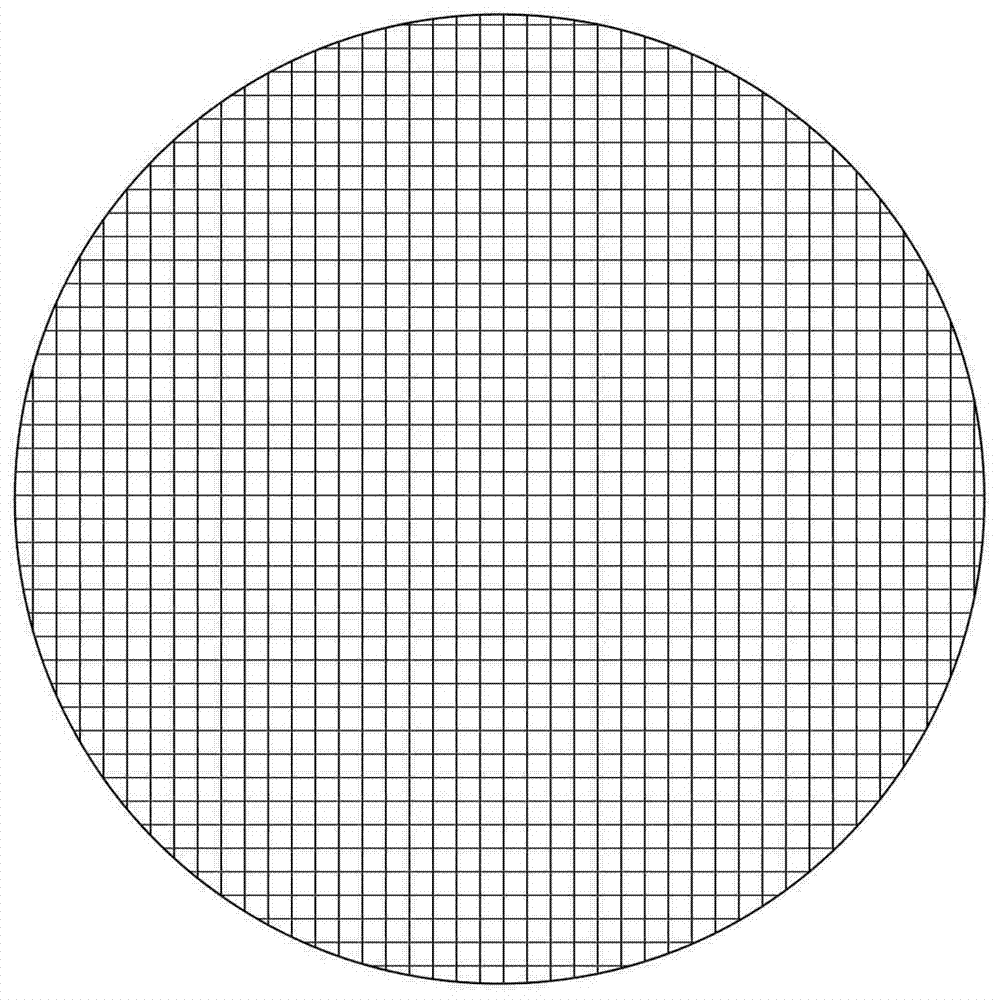

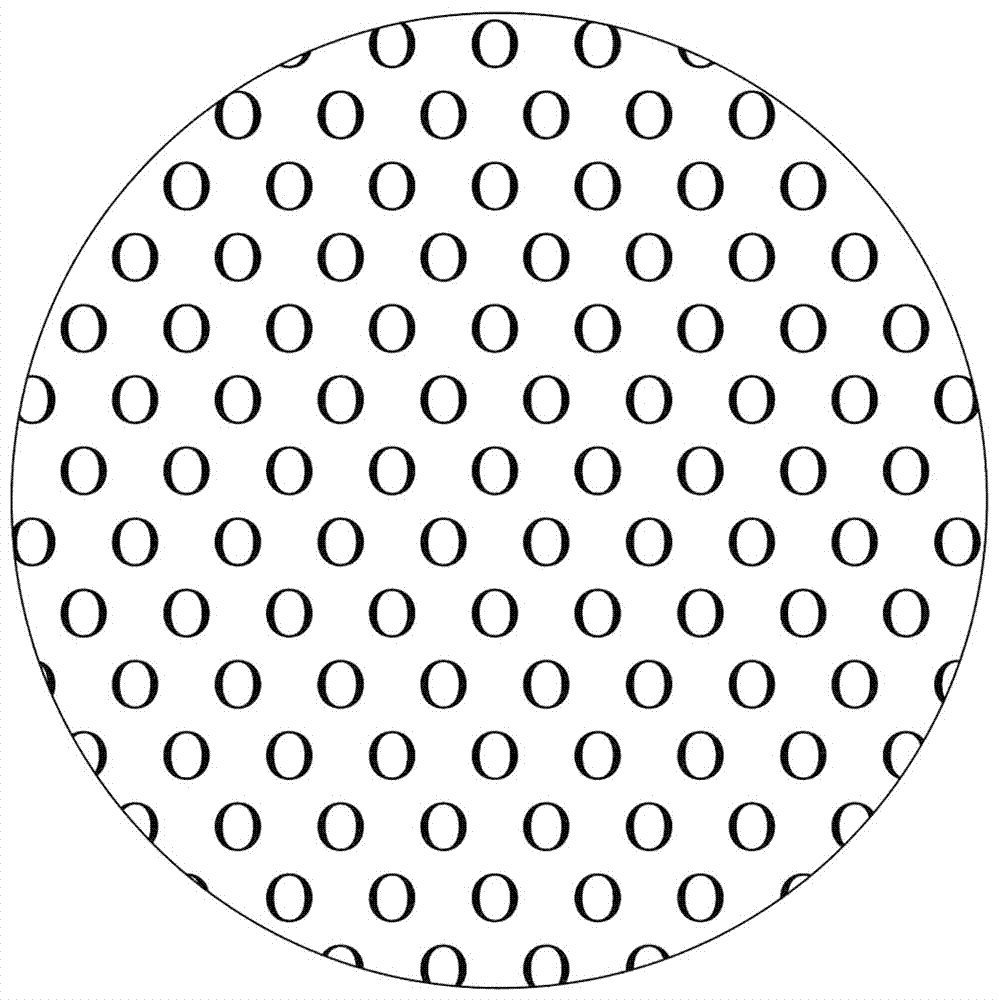

[0014] Embodiment 1, see appendix figure 1 , attached figure 2 , attached image 3 , attached Figure 4 , attached Figure 5 , a continuous vacuum degassing device, comprising a head 1, an air inlet 102, a feed port 103, an air extraction port 104, a barrel body 2, a discharge port 201, a sight glass 105, a vacuum gauge 101, a frame 202, a barrel The upper and lower half sections in the body are fixed with a stopper 203, a screen 4 is placed on the upper stopper, an oval guide body 3 is connected on the screen, and an orifice 6 is placed on the lower stopper in the barrel body. There are several to dozens of umbrella-shaped screens 5 with the convex surface facing upwards stacked, and the discharge end of the feed port is an umbrella-shaped, and a certain gap is maintained with the surface of the oval-shaped guide body.

[0015] The gap between the discharge end of the feed inlet and the surface of the oval guide body is 1-10mm.

[0016] The hole diameter of said orifice...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com