Device and process for preparation of iron salt through comprehensive utilization of copper smelting tailings

A technology of copper smelting and tailings, which is applied in the field of device technology for comprehensive utilization of copper smelting tailings to prepare iron salts, can solve the problems of high consumption of iron salts, dependence on purchased products, high equipment and operating costs, and achieve cost savings, The effect of reducing dependence and reducing the consumption of iron salts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

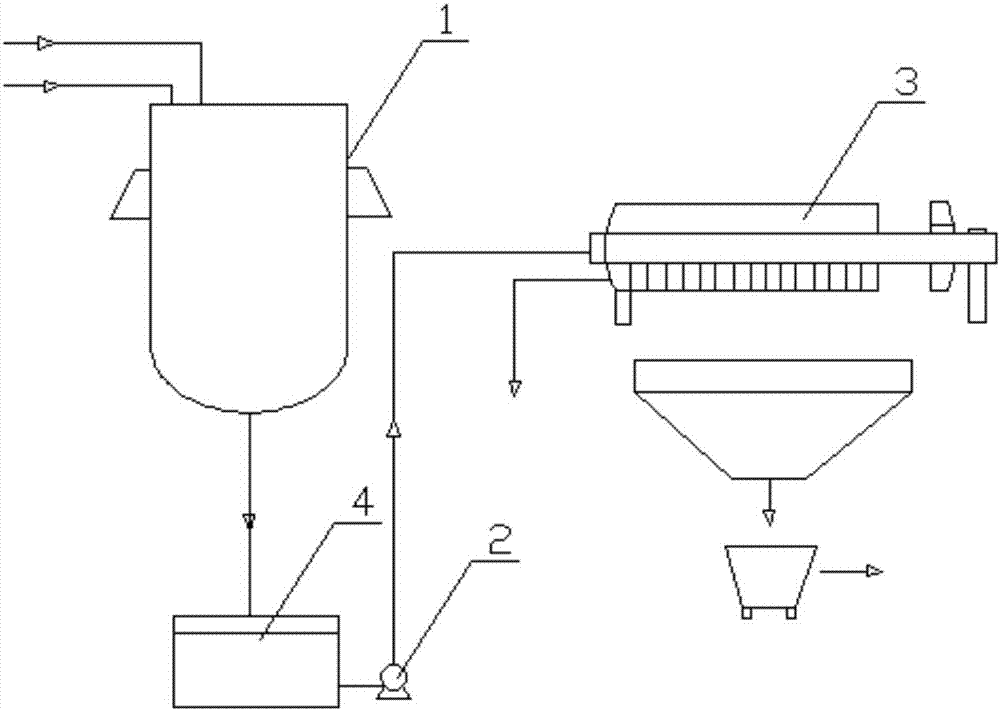

[0020] A device for comprehensively utilizing copper smelting tailings to prepare iron salts. The equipment for the device for comprehensively utilizing copper smelting tailings to prepare iron salts includes:

[0021] An open reaction kettle with stirring 1, a solution lift pump 2, a filter press 3 and a solution storage tank 4.

[0022] Preferably, the stirred open reaction kettle 1 is connected to a solution storage tank 4 , the solution storage tank 4 is connected to a solution lifting pump 2 , and the solution lifting pump 2 is connected to a filter press 3 .

[0023] A process for comprehensively utilizing copper smelting tailings to prepare iron salt is characterized in that the process for comprehensively utilizing copper smelting tailings to prepare iron salt is briefly described as:

[0024] The tailings produced by copper smelting and some scrap iron scraps are reacted with dilute sulfuric acid in a certain proportion, and the resulting solid-liquid mixture is then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com