Photo-curing 3D printer

A 3D printer and light curing technology, applied in 3D object support structures, additive manufacturing, processing drive devices, etc., can solve the problems of low printing efficiency and printing output at one time, inability to complete multiple products at the same time, and unfavorable full utilization of the body, etc. Achieve the effect of simple structure, reduced printing cost and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

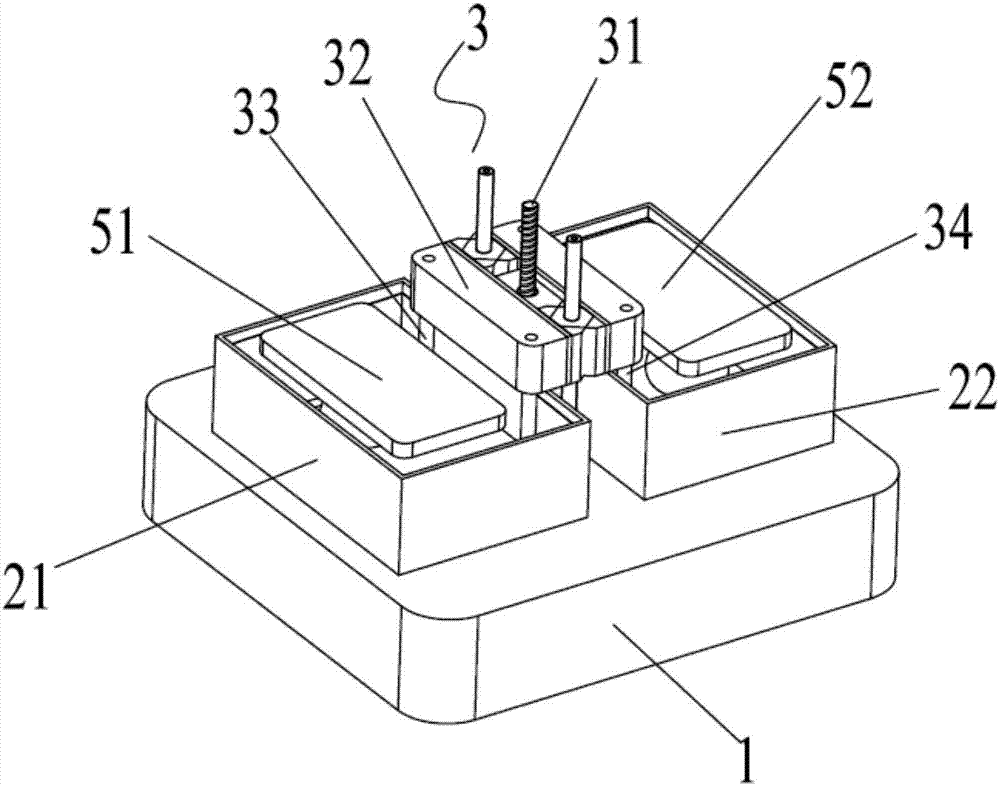

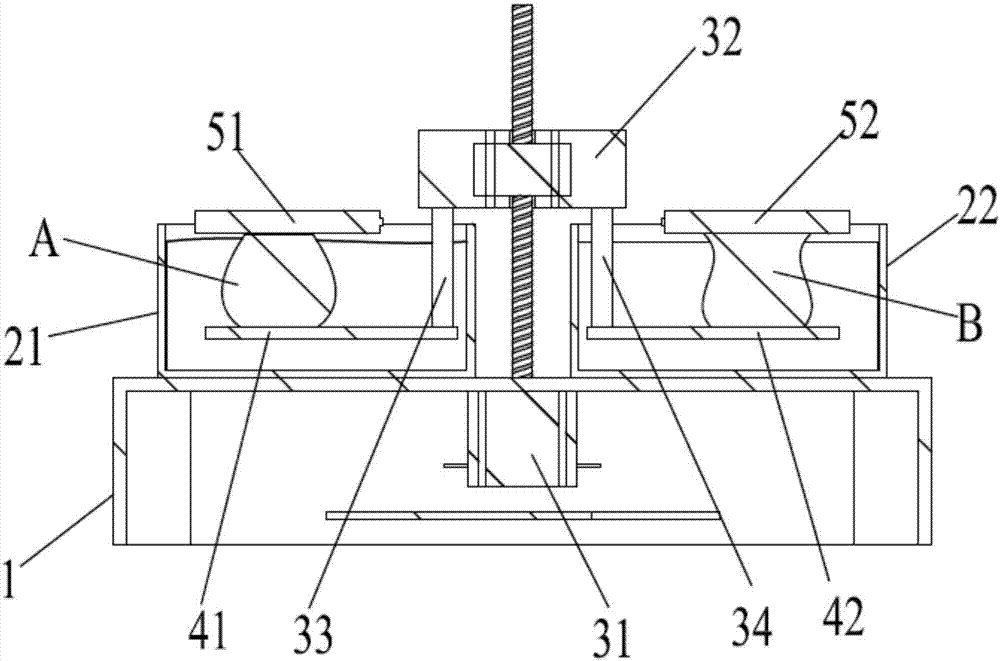

[0024] The light-curing 3D printer in Embodiment 1 includes a fuselage base, multiple resin cylinders, a lifting mechanism, multiple printing platforms, multiple projection panels, and multiple groups of curing light sources whose number is the same as the number of resin tanks. The plurality of resin cylinders are arranged on the top surface of the fuselage base. The lifting mechanism is arranged outside the plurality of resin cylinders. For example, the plurality of resin cylinders can be arranged around the periphery of the lifting mechanism, or arranged in parallel outside one side of the lifting mechanism. The plurality of printing platforms are respectively driven and connected to the lifting mechanism, and can be driven by the lifting mechanism to simultaneously move linearly in the plurality of resin cylinders along the height direction of the resin cylinder, and the printing surface of each printing platform parallel to the bottom surface of its corresponding resin va...

Embodiment 2

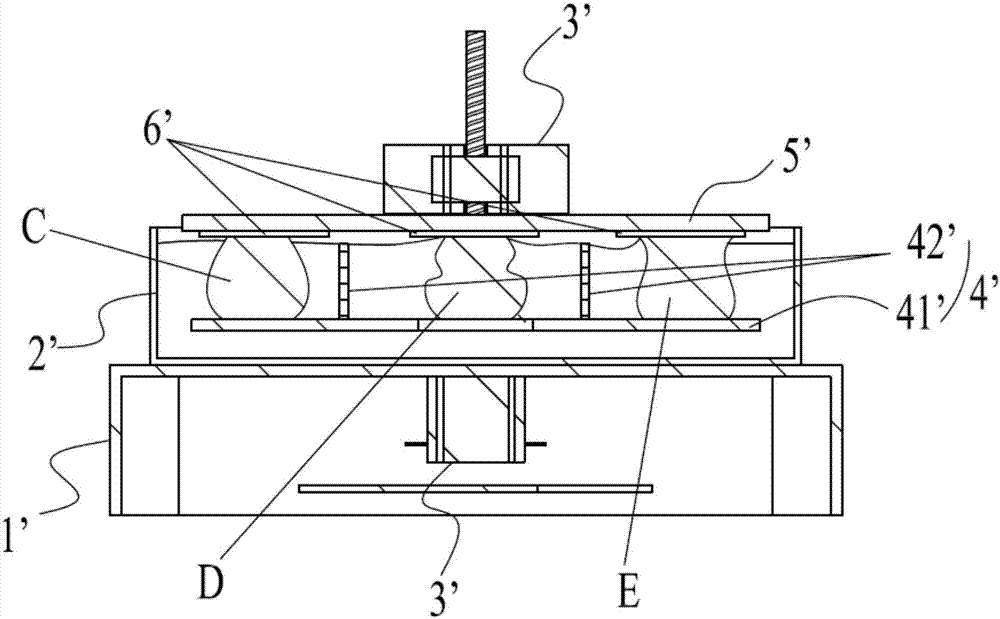

[0033] see image 3 , The light-curing 3D printer in this embodiment 2 includes a body base 1', a resin cylinder 2', a lifting mechanism 3', a printing platform 4', a projection panel 5' and multiple groups of curing light sources 6'. The resin cylinder 2' and the lifting mechanism 3' are adjacently arranged on the top surface of the fuselage base 1'. The printing platform 4' is drivingly connected with the lifting mechanism 3', and can be driven by the lifting mechanism 3' to move linearly along the height direction of the resin cylinder 2' in the resin cylinder 2'; and the printing platform 4' includes a printing Substrate 41' and a plurality of printing partitions 42'; the printing surface of the printing substrate 41' is parallel to the bottom surface of the resin cylinder 2', and the plurality of printing partitions 42' are arranged at intervals on the printing surface of the printing substrate 41' , each space between two adjacent printing partitions forms a printing sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com