Energy-saving efficient leather embossing machine

An embossing machine and leather technology, which is applied to leather surface mechanical treatment, mechanical equipment, fluid pressure converters, etc., can solve the problems of high-power motors with large volume, unfavorable press layout, and low efficiency, and achieve ingenious structural design, The effect of convenient leather loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing:

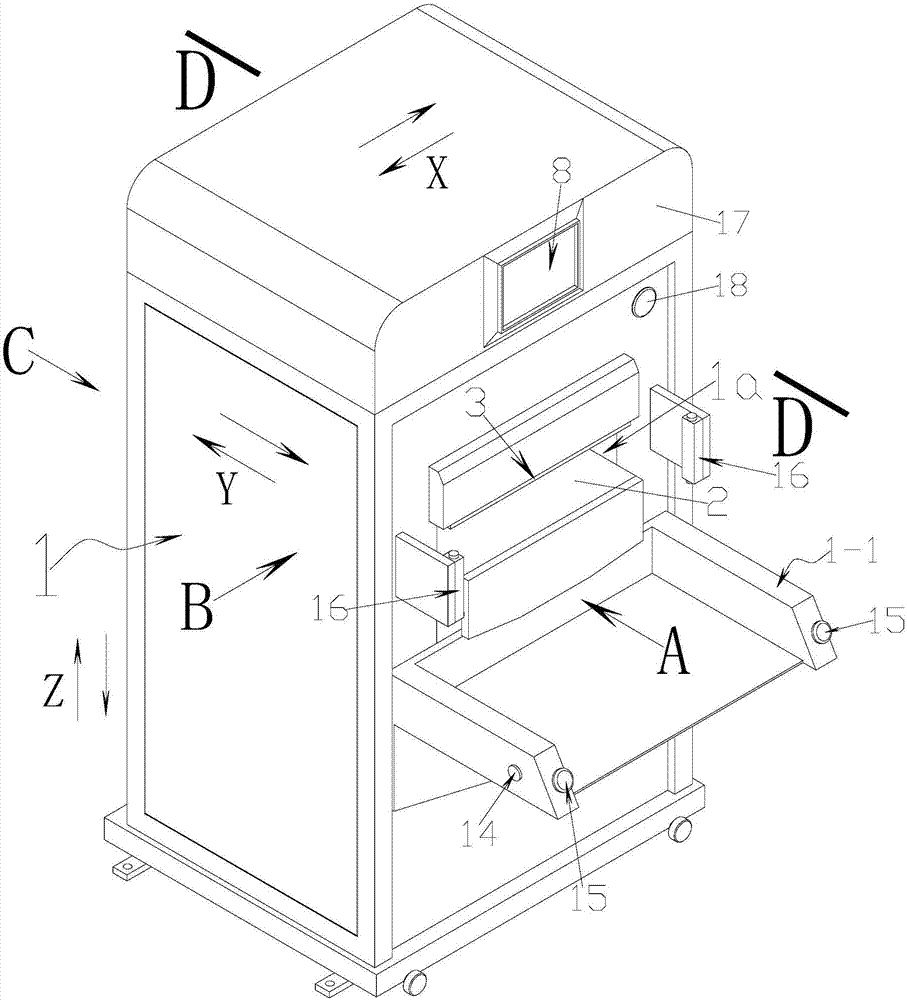

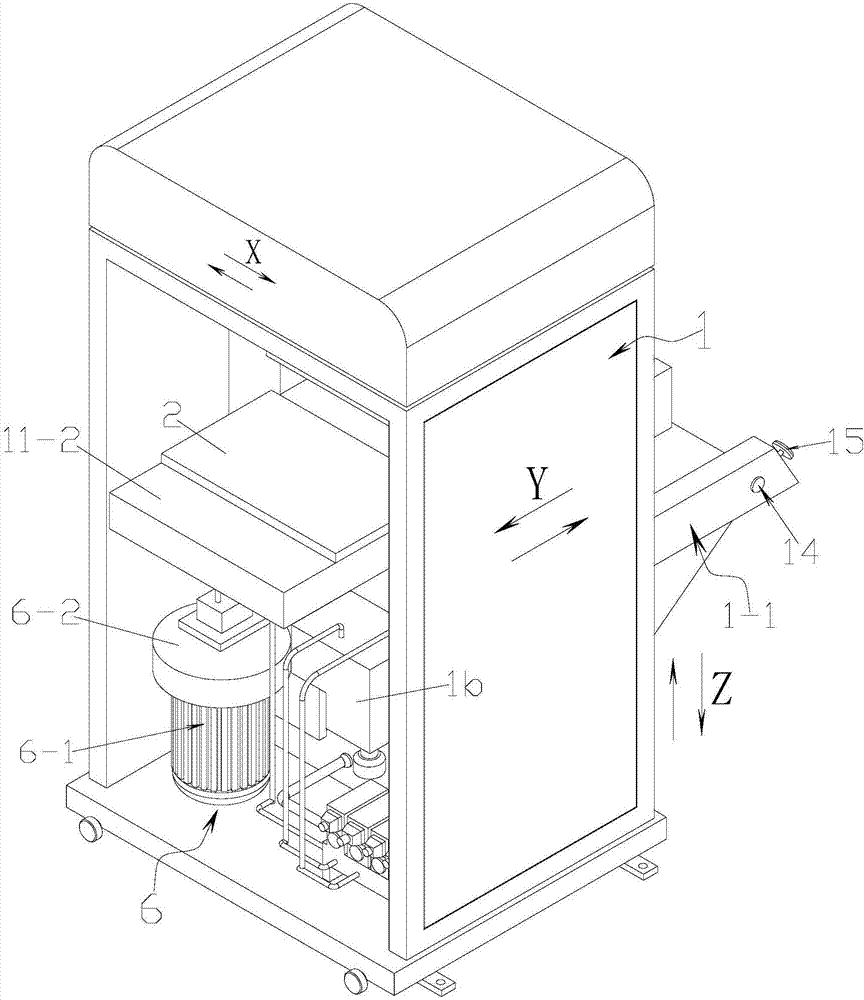

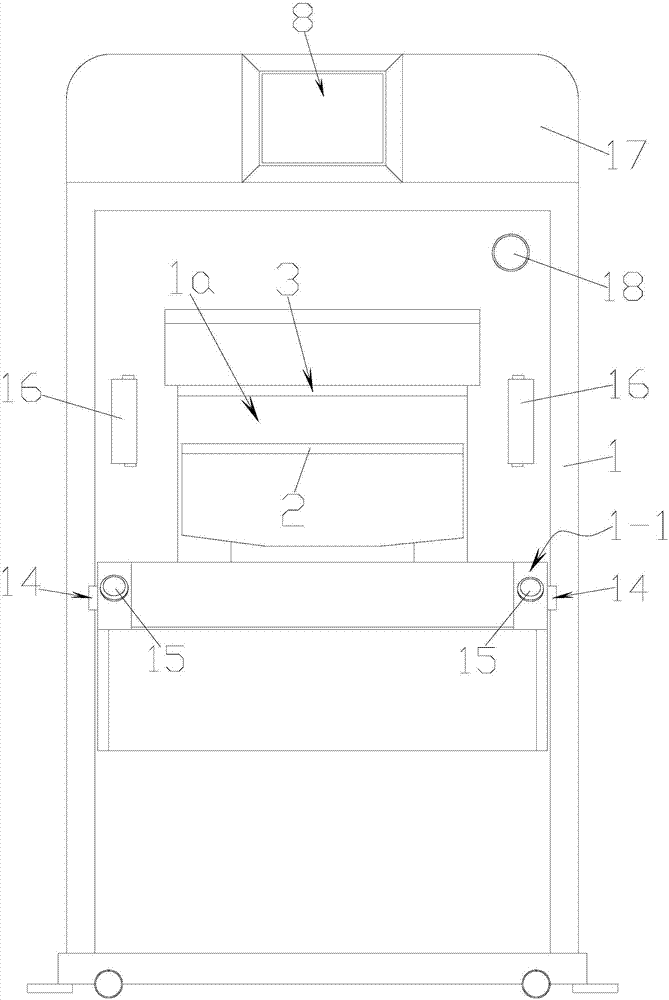

[0028] Referring to the accompanying drawings: this energy-saving and high-efficiency leather embossing machine includes a frame 1, a workbench 1a is arranged on the frame 1, an oil storage tank 1b and an oil tank 1c are fixed on the frame 1, and a lower electric heater is installed at the bottom of the workbench 1a. Plate 2, the upper electric heating plate 3 is fixed on the top of the workbench 1a, and the large hydraulic cylinder 4 for driving the lower electric heating plate 2 to move upward along the "Z" direction and the piston for driving the large hydraulic cylinder 4 are arranged under the lower electric heating plate 2 The rod moves up and down along the "Z" direction of the small hydraulic cylinder 5, and the oil circuit control system 6 for controlling the large hydraulic cylinder 4 and the small hydraulic cylinder 5 is fixed on the frame 1. The oil circuit contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com