Manufacturing method of golden fingers at ladder position

A manufacturing method and golden finger technology, which is applied in the fields of printed circuit manufacturing, reinforcement of conductive patterns, formation of electrical connection of printed components, etc., can solve problems affecting the integrity of signal transmission, insufficient bonding force of two-layer core boards, and affecting the quality of high-layer boards, etc. problems, to achieve the effect of improving insufficient binding force, avoiding resin voids, avoiding pollution or scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

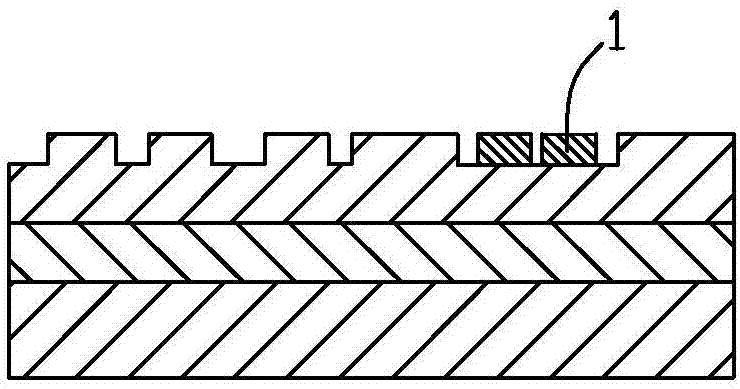

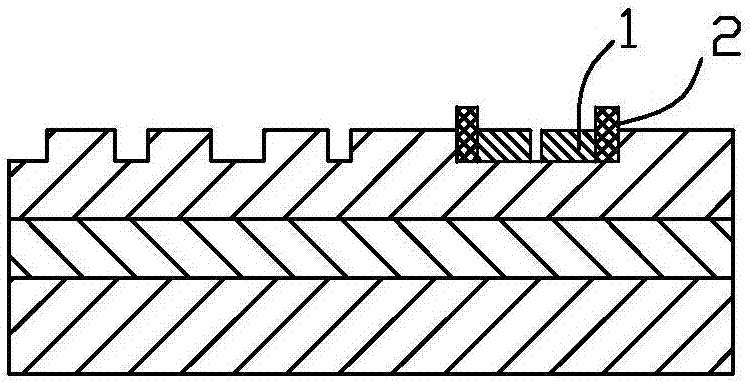

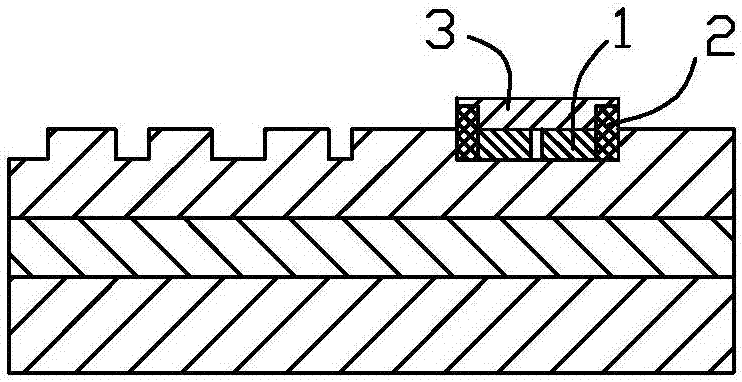

[0032] refer to Figure 1 to Figure 8 , the present invention provides a method for making a stepped golden finger, which specifically includes the following steps:

[0033] S1. Cover a layer of solder resist ink 2 on the surface of the step area of the laminated substrate, wherein the step area is provided with a gold finger pattern 1 and a gold finger guide line. When the solder resist ink 2 is covered, the solder resist ink 2. It cannot be covered on the gold finger pattern 1 and the gold finger guide line, that is, the gold finger pattern 1 and the gold finger guide line must be exposed, and then the solder resist ink 2 is cured;

[0034] S2. Attach a high-temperature protection tape 3 on the surface of the step area, the thickness of the high-temperature protection tape 3 is 0.05 mm, and the temperature-resistant temperature of the high-temperature protection tape 3 without residual glue is greater than the pressing temperature of the pressing process;

[0035] S3. Sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com