Whole set of automatic sargassum fusiforme processing device

A kind of processing equipment, hijiki technology, applied in the field of a complete set of automatic hijiki processing equipment, can solve the problems of troublesome and time-consuming processing process, poor quality hijiki, etc., and achieve the effect of improving efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

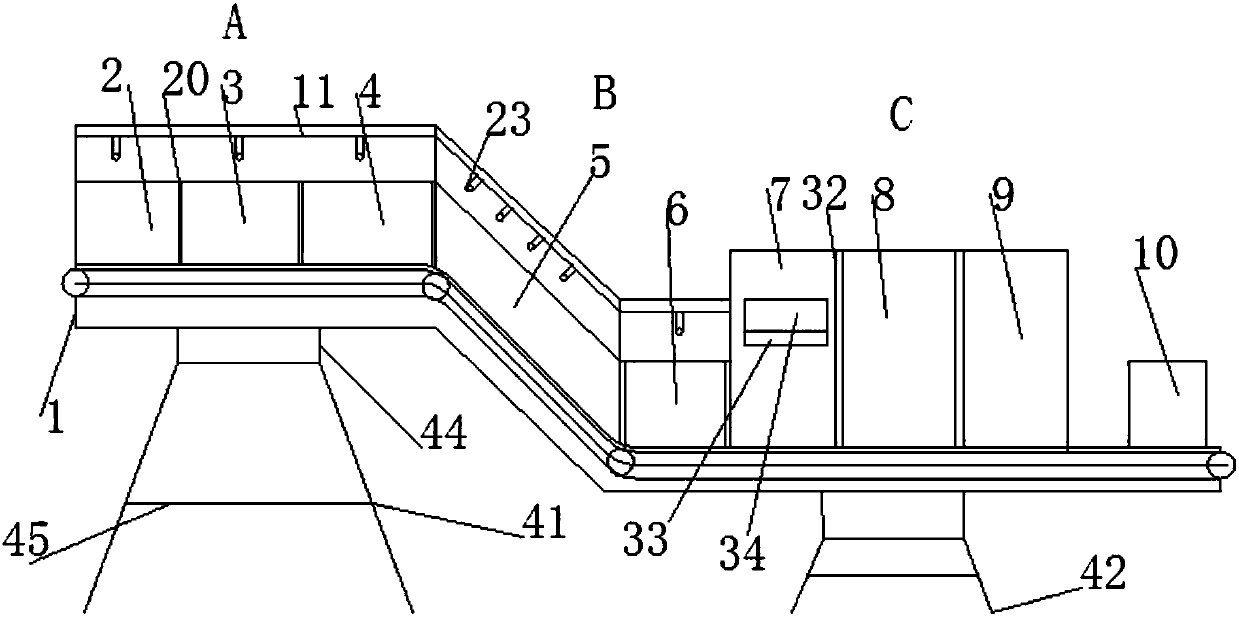

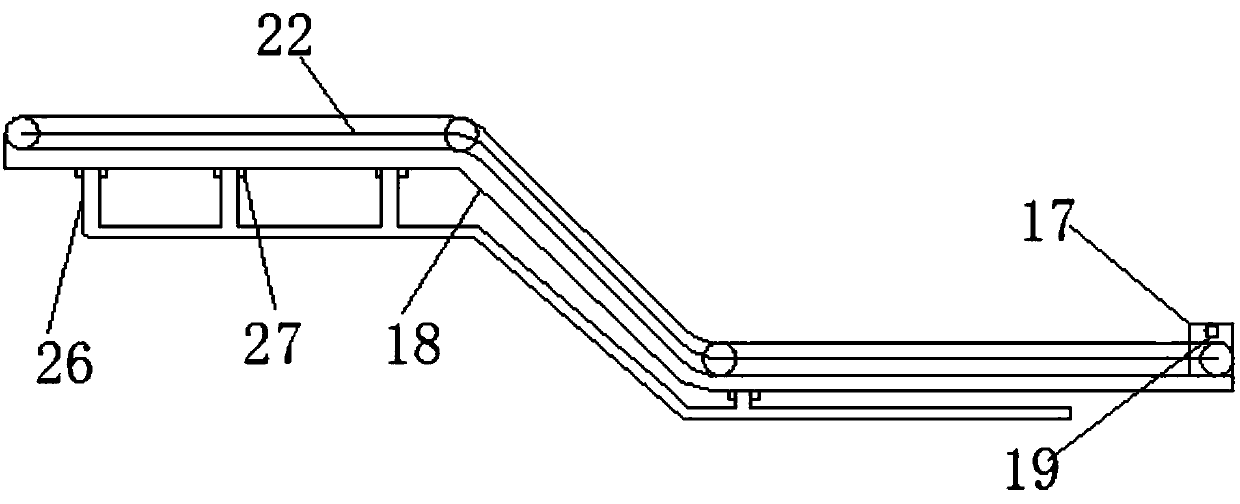

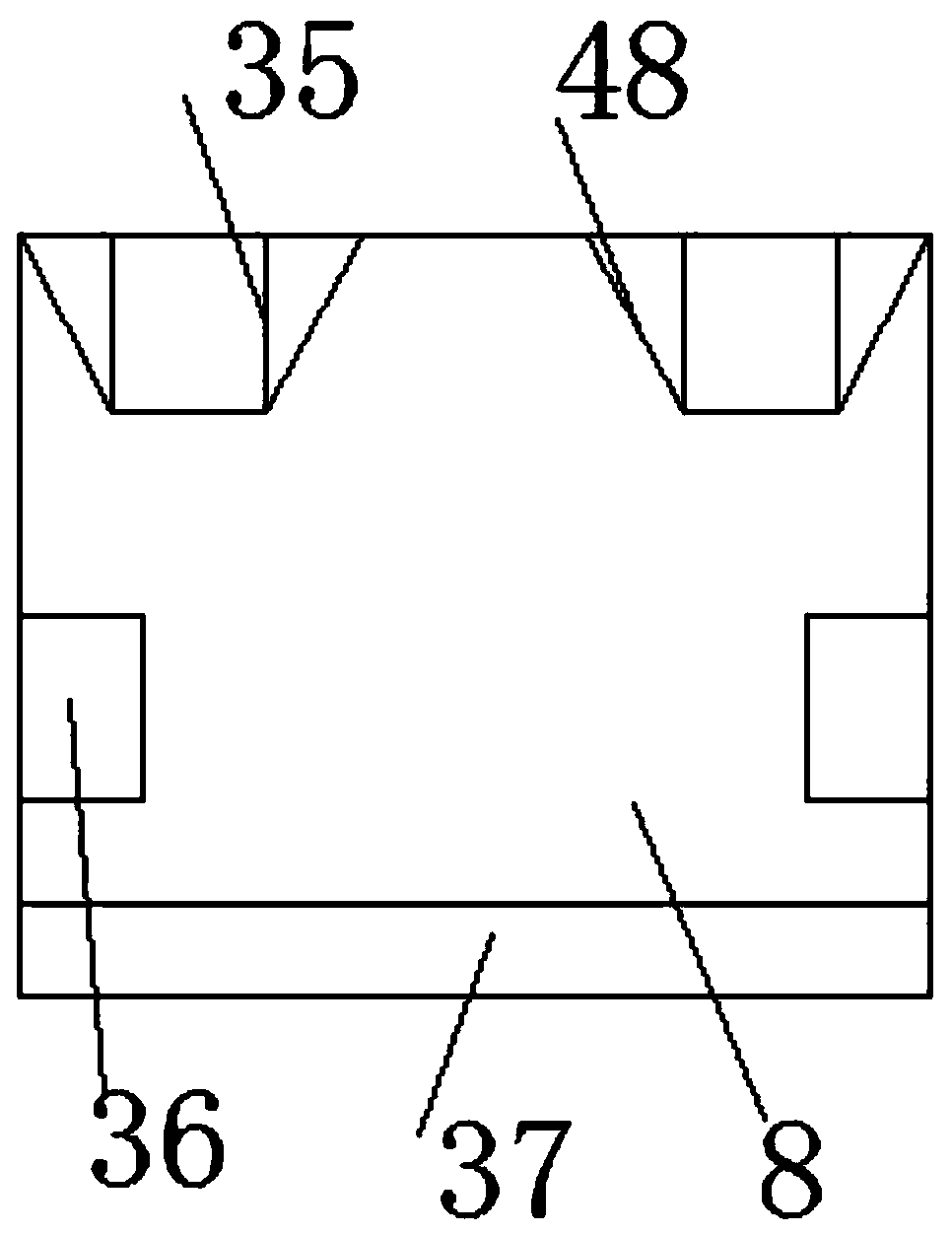

[0029] Embodiment 1 refers to Figure 1-9, a full set of automatic hijiki processing equipment, including a working layer, a conveyor belt 1 and a support, the working layer includes a first working layer A, a second working layer B and a third working layer C, the first working layer A cleaning chamber 2, arsenic removal chamber 3 and fishy smell removal chamber 4 are sequentially arranged in A, a washing chamber 5 and a soaking chamber 6 are sequentially arranged in the second working layer B, and a cooking chamber 7 is sequentially arranged in the third working layer C , dry sorting room 8, sterilization packaging room 9 and control center 10; the first working layer A, the second working layer B and the third working layer C are located on the conveyor belt 1, and the first working layer A and the second working layer Water injection pipeline 11 is arranged on B, and water injection support frame 12 is arranged on both sides of transmission belt 1, and water injection pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com