A Combined Stirring Paddle for Improving Suction Capability and Mixing Efficiency

A technology of mixing efficiency and suction capacity, applied in the field of combined stirring paddles, which can solve problems such as unfavorable mixing, emulsification, and excessive stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

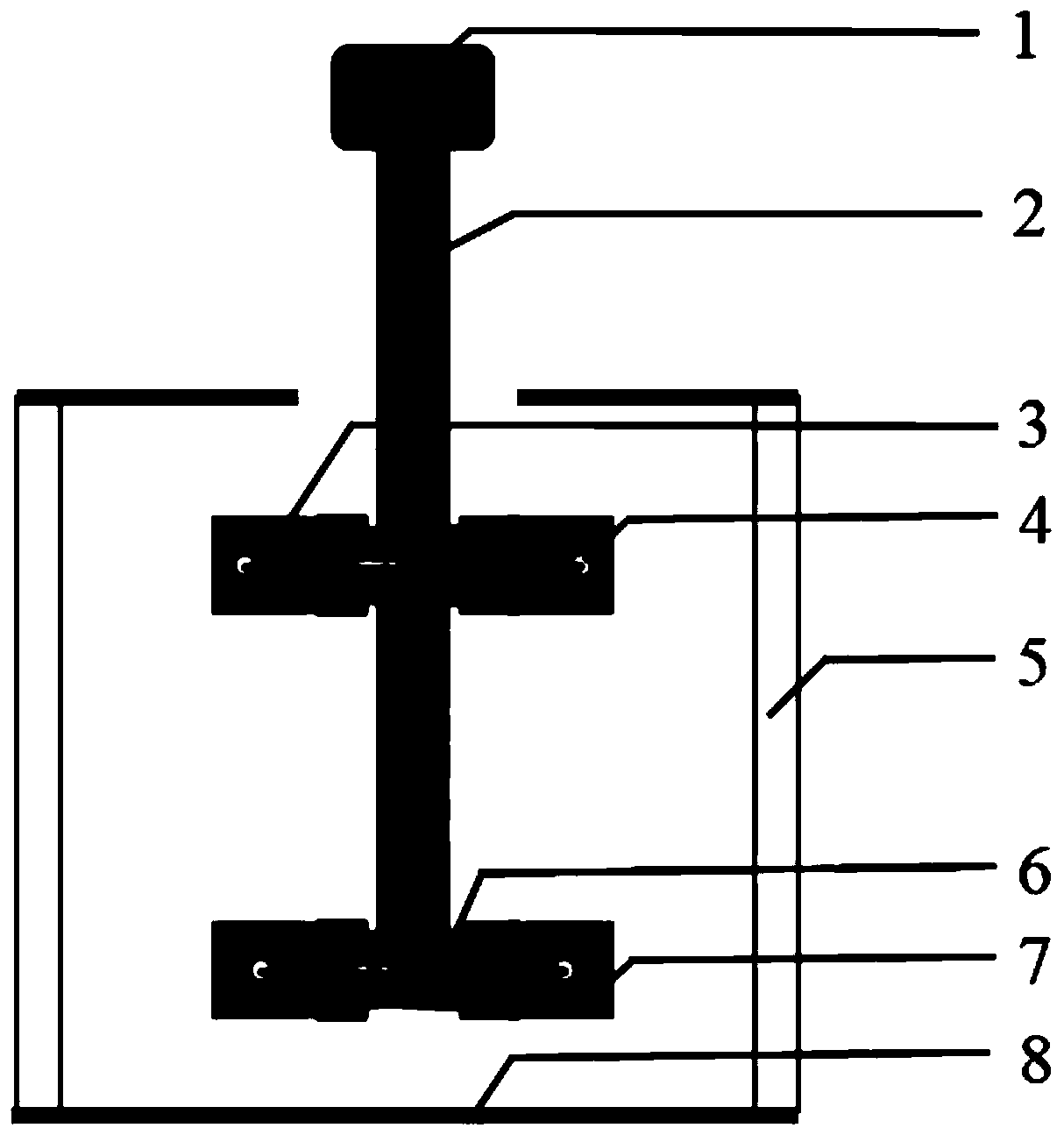

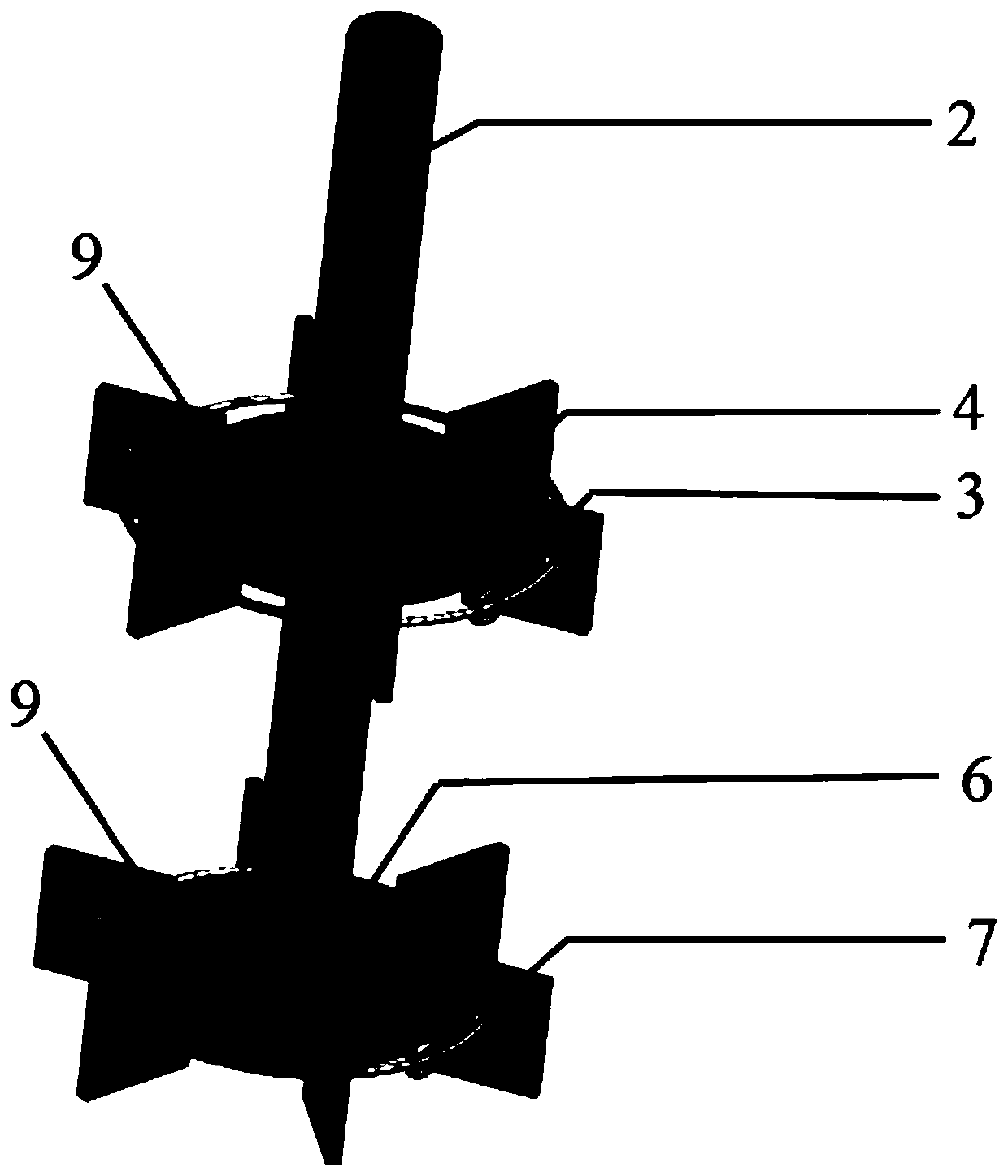

[0025] A combined stirring paddle that improves suction capacity and mixing efficiency is characterized in that: it mainly includes a stirring shaft 2, and at least two disc bodies 9, flexible ropes 6 having the same number as the disc bodies 9, several rigid Paddle 7.

[0026] The stirring shaft 2 is a circular shaft, one end of which is connected to power, and the other end is located in the stirring tank 8 .

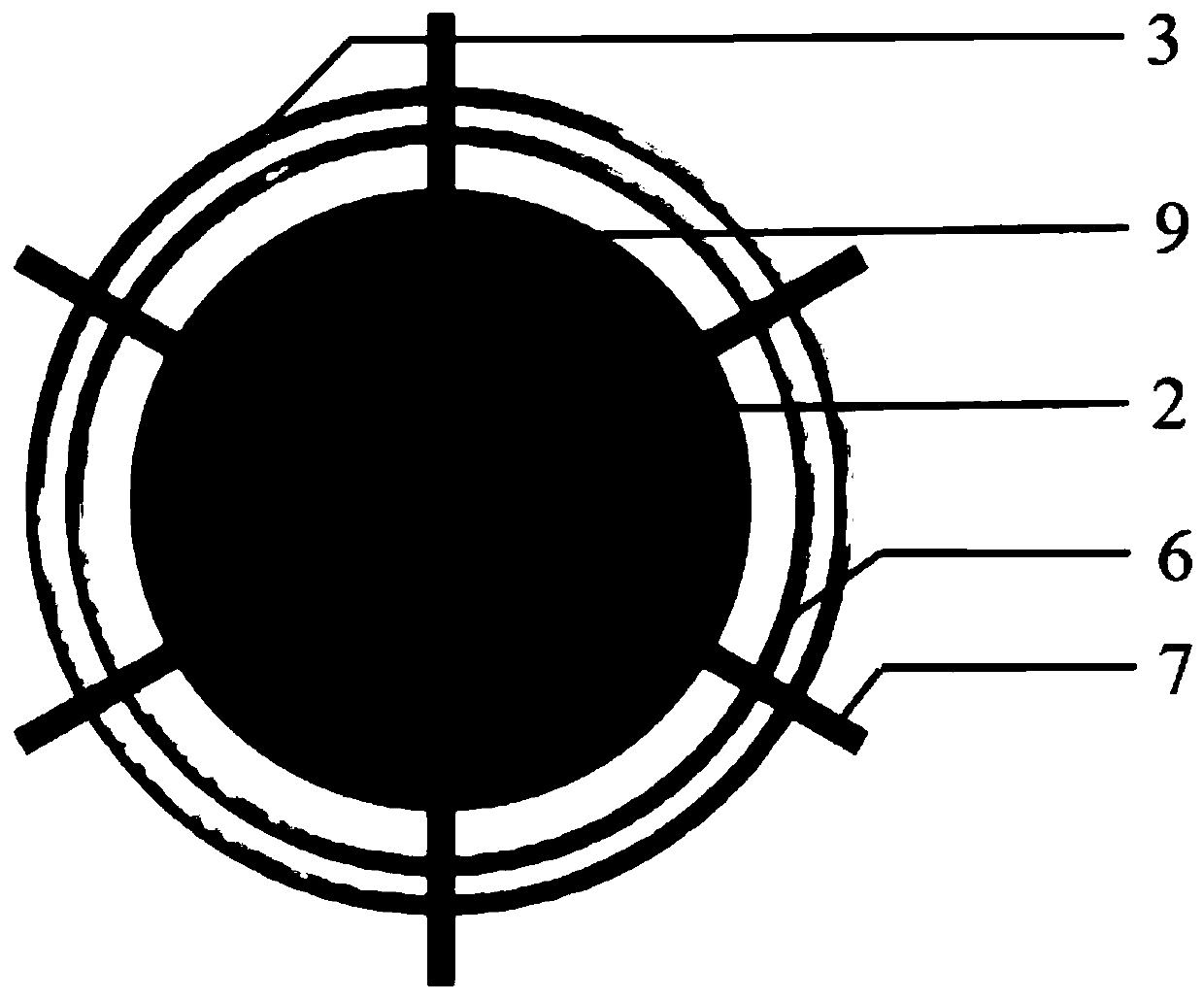

[0027] Each disc body 9 is fixed on the stirring shaft 2 . The stirring shaft 2 penetrates the central hole of each disc body 9 .

[0028] Each disc body 9 is fixed with several rigid paddles 7 . These rigid paddles 7 are inserted around the disc body 9 and surround the stirring shaft 2 radially.

[0029] Each rigid paddle 7 has a circular through hole 4 .

[0030] Each disc body 9 is configured with a flexible rope 6 . After a flexible rope 6 passes through each circular through hole 4 on all the rigid paddles 7 around a disc body 9 in turn, the two ends of the ...

Embodiment 2

[0033] The main structure of this embodiment is the same as that of Embodiment 1, and further, the two nodes on the stirring shaft 2 are respectively marked as node I and node II. Node I is close to the end of the stirring shaft 2 connected to the motor 1, and node II is close to the lower end of the stirring shaft 2.

[0034] The two disc bodies 9 are respectively denoted as disc body I and disc body II. Disc body I and disc body II are respectively fixed at node I and node II. That is, the stirring shaft 2 has two layers of combined stirring paddles up and down.

[0035] The number of blades of the rigid paddles 7 connected by the disc body I and the disc body II is equal. The number of blades of the rigid stirring paddle 7 is at least three.

Embodiment 3

[0037] The main structure of this embodiment is the same as embodiment 1 or 2, further:

[0038] The blade length of the rigid paddle 7 is L. The end of the rigid paddle 7 away from the stirring shaft 2 is the tip, and the distance between the circular through hole 3 and the tip of the rigid paddle 7 is a. a<2 / 3L. The circular through-holes 4 on each blade are located at the same position

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com