Charged polishing machine for high-voltage disconnecting switch contact

A high-voltage isolating switch and polishing machine technology, which is applied in the direction of switchgear, surface polishing machine tools, grinding/polishing equipment, etc., can solve difficult problems such as realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

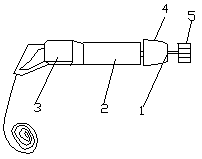

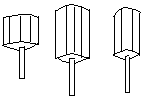

[0011] Such as Figure 1-2 As shown, a high-voltage isolating switch contact point polishing machine according to an embodiment of the present invention includes a polisher 1, an insulating support rod part 2, and a power source part 3. The polisher 1 and the insulating support rod part 2 It is connected with the power source part 3 in turn, and the polisher 1 is composed of an insulating operation part 4 and a polishing wheel 5. The polisher 1 and the insulating support rod part 2 are connected by a shaft, and the polishing wheel 5 is connected to the insulating Support rod part 2 top. The power source part 3 is a small motor with a power cord, which is suitable for a wider range of work. The size and size of the polishing wheel 5 can be replaced according to actual needs.

[0012] In order to overcome the deficiencies of the exis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com