Novel streetcar subgrade structure

A technology for trams and roadbeds, applied in roads, tracks, buildings, etc., can solve the problems of large width and thickness of roadbeds, great impact on the surrounding environment, secondary excavation of backfill soil, etc., so as to improve construction efficiency and avoid secondary Effect of excavation and reduction of excavation depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

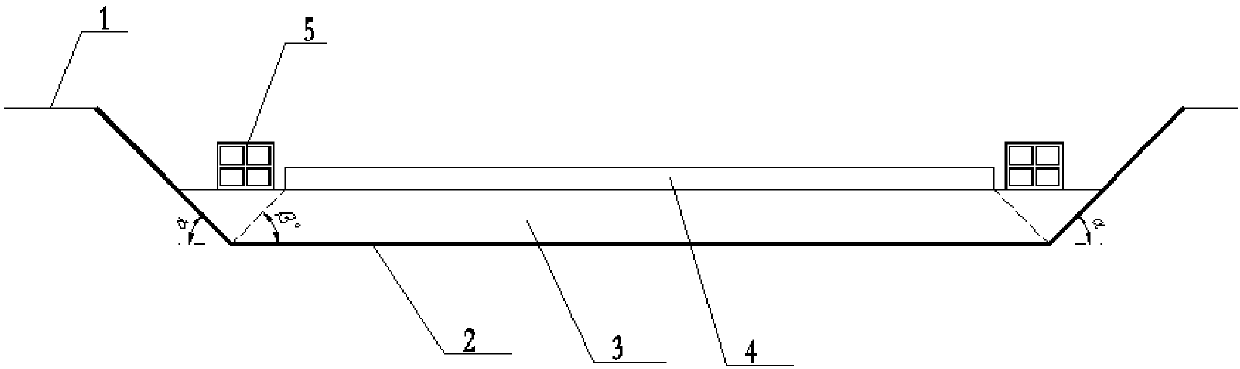

[0019] Such as figure 1 Shown is a new tram subgrade structure provided by this embodiment, including an excavation trench, the excavation trench is an inverted ladder-shaped structure, and the bottom of the excavation trench is laid with a filled road base 3 , the upper surface of the filling road base 3 is provided with a support plate 4, and the depth range of the excavation trench is 1.1-1.7m. In the present embodiment, the depth H=1.4m of the excavation trench is taken, and the excavation trench The top opening width range of digging trench is 9-13m, gets the top opening width L=11m of digging trench in the present embodiment, and the thickness range of described filling road base 3 is 0.5-1m, takes in the present embodiment The thickness of the filling road base 3 is 0.8m, and the thickness range of the support plate 4 is 0.1-0.2m. In the present embodiment, the thickness of the support plate 4 is 0.1m, and the width range of the support plate 4 is 2.4-0.2m. 2.8m, get t...

Embodiment 2

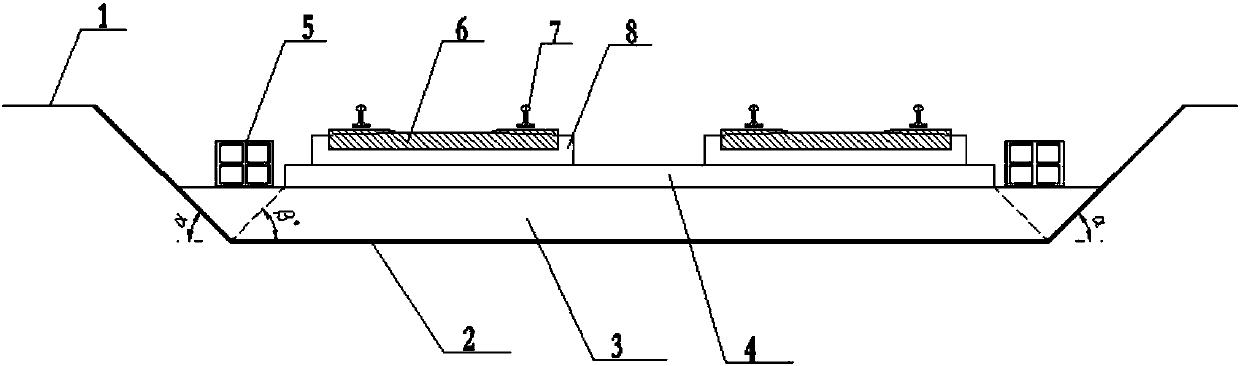

[0022] Such as figure 2 The embodiment shown in this example provides a novel integrated tramway subgrade track structure, including a track structure and a novel tramway subgrade structure described in Embodiment 1, and the track structure includes a ballast bed 8, sleepers 6 and steel rails 7. The support plate 4, ballast bed 8, sleeper 6 and rail 7 are sequentially connected from bottom to top, the number of the track structure is 2, and the width of the ballast bed 8 is 2.4m. The upper surface of the filling road base 3 is paved with a soil layer. After the tram track is laid, the soil layer is filled in the excavated trench, and further for better recovery of the ground, the backfill soil layer is carried out as road Hardening, sidewalk paving, vegetation restoration and other measures.

[0023] The specific construction process of this embodiment includes the following steps: a. Pipeline relocation, traffic relief, construction enclosure, site leveling and foundation t...

Embodiment 3

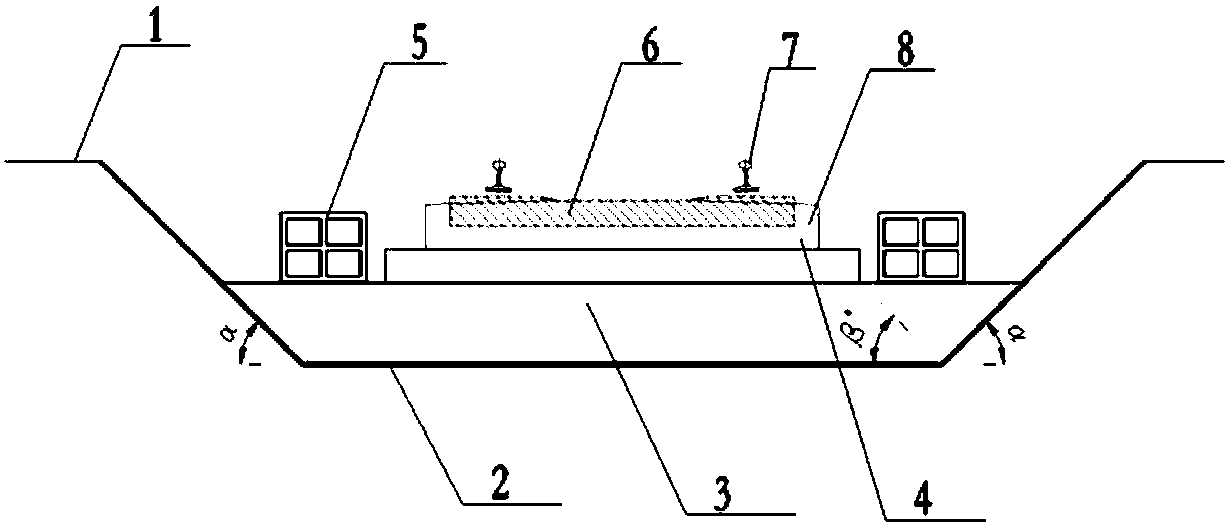

[0026] Such as image 3 It is shown that this embodiment provides a new type of integrated tramway subgrade track structure. The difference between this embodiment and Embodiment 2 is that the number of the track structure is one.

[0027] Other structures in this embodiment are the same as those in Embodiment 2, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com