Anti-electricity shed crossing multiple existing electrified railways and construction method

A technology for electrified railways and construction methods, which is applied in the direction of erecting/assembling bridges, bridges, buildings, etc., and can solve the problem that insulation and anti-electricity isolation materials cannot meet the requirements of insulation and anti-electricity isolation, poor anti-tilt and anti-overturning stability, and low catenary line voltage and other issues, to achieve the effect of protecting normal and safe operation, fast construction speed and protecting safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The technical solutions of the present invention will be further described below through specific examples.

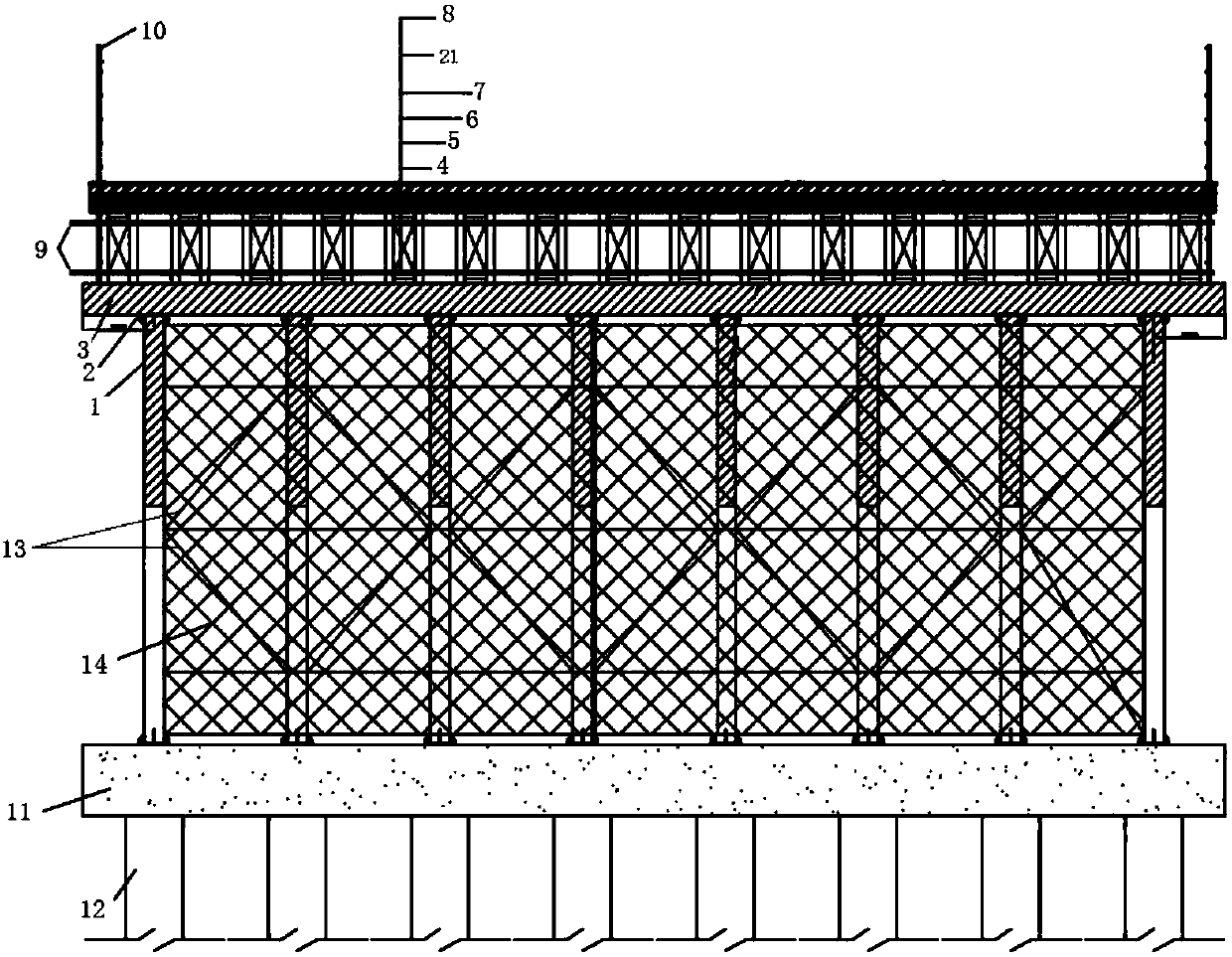

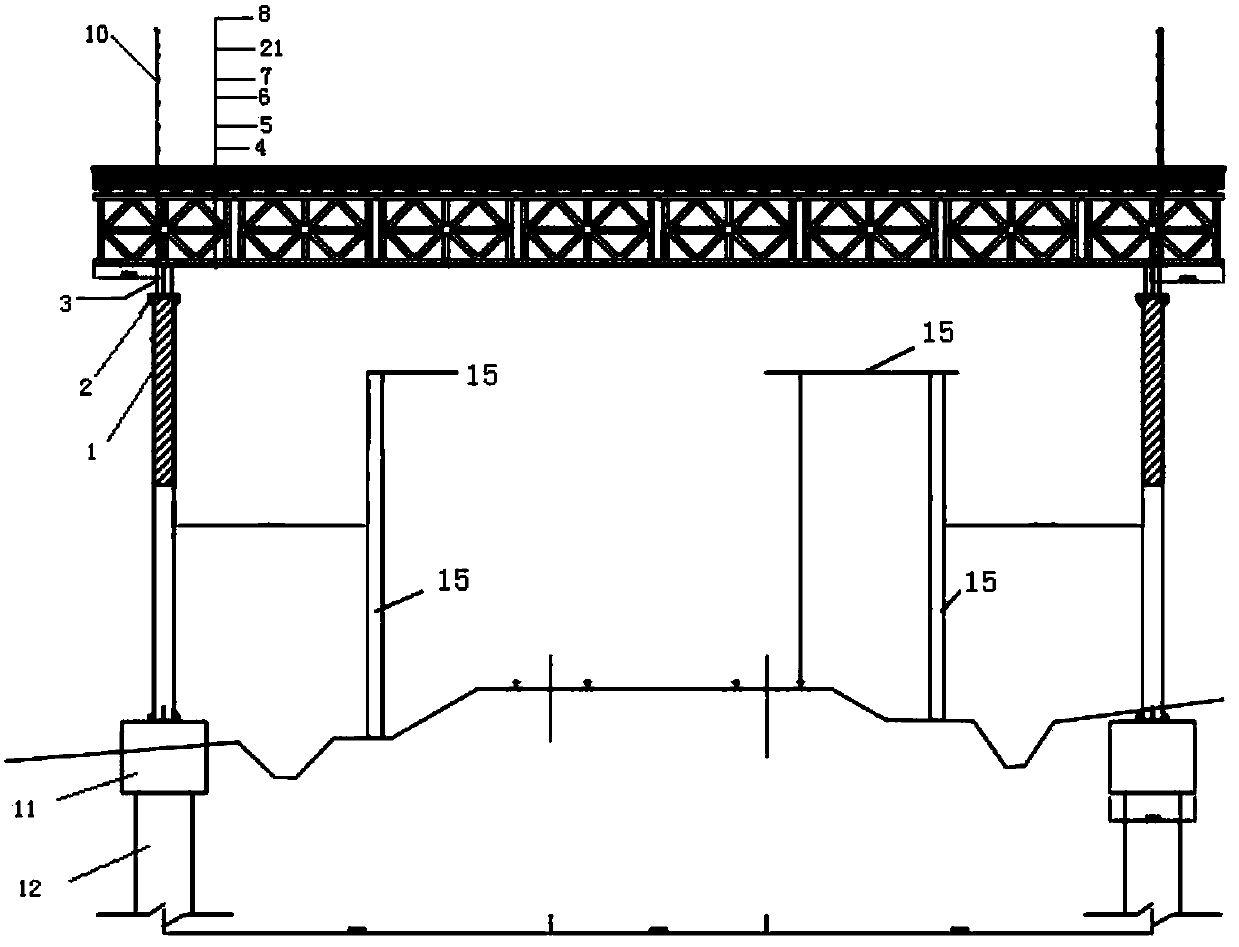

[0061] Such as Figure 1-7 Shown, a kind of construction method of the anti-electric shed spanning a plurality of existing electrified railways, it comprises the following technical steps:

[0062] Step 1, laying artificial hole-digging piles 12 on both sides of the track group to be crossed;

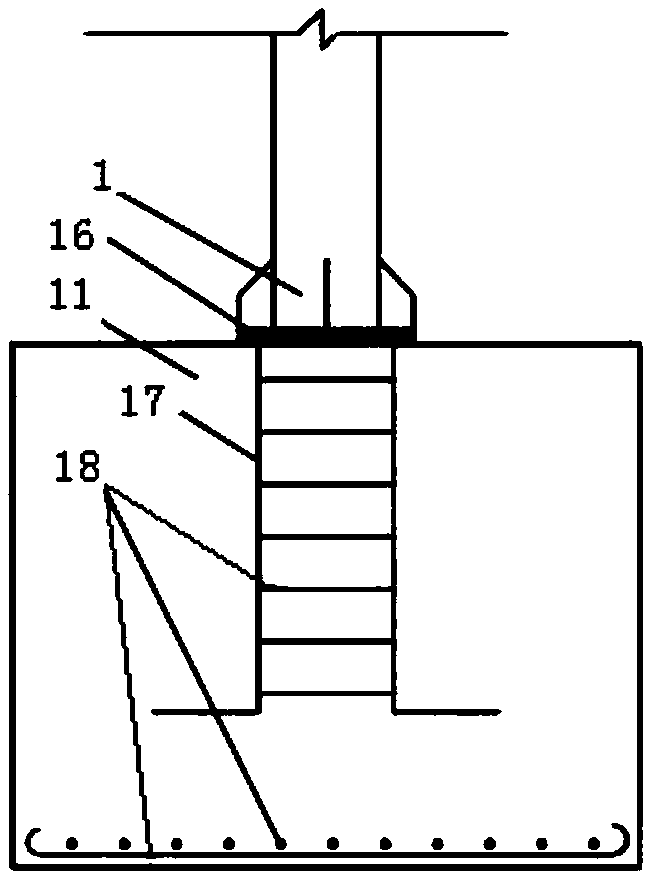

[0063] Step 2, constructing a strip foundation 11 on top of the above-mentioned pile 12, and reserving column anchor bolt holes;

[0064]Step 3, install the column 1 on the strip foundation 11 and install the channel steel diagonal brace 13, the column 1 is a φ425mmx8mm steel column;

[0065] Step 4, the top of the column 1 is welded with a 625mmx625mmx20mm steel backing plate 2, and the steel backing plate 2 is an I-beam I630b type crossbeam 3, and the crossbeam 3 is arranged along the running direction of the track group;

[0066] Step five, set up the sixty-four typ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com