Three-dimensional laser scanning head

A three-dimensional laser, scanning head technology, applied in optics, optical components, instruments, etc., to achieve the effect of realizing large-scale full-angle scanning, improving motion accuracy and motion speed, and improving scanning speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

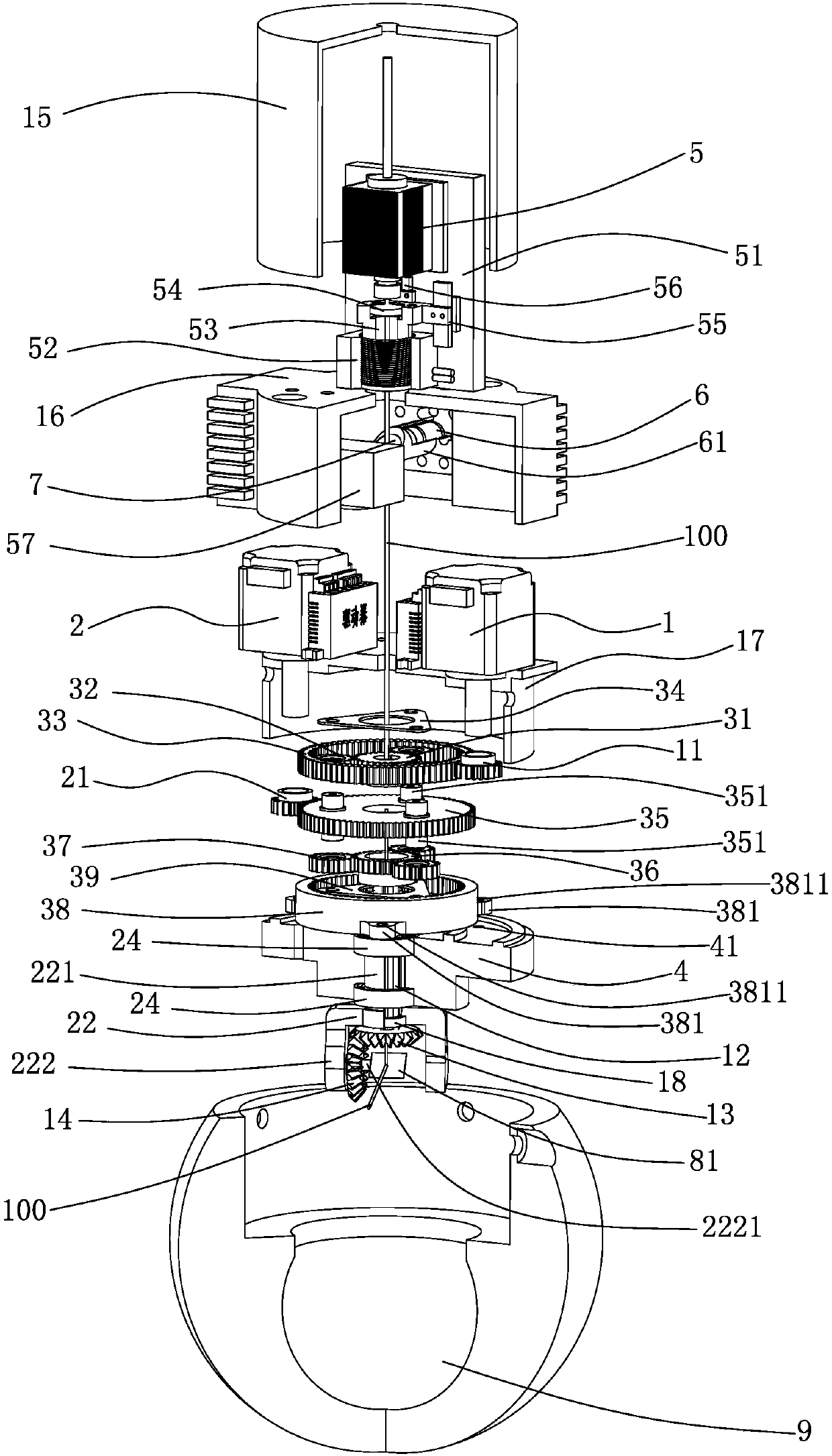

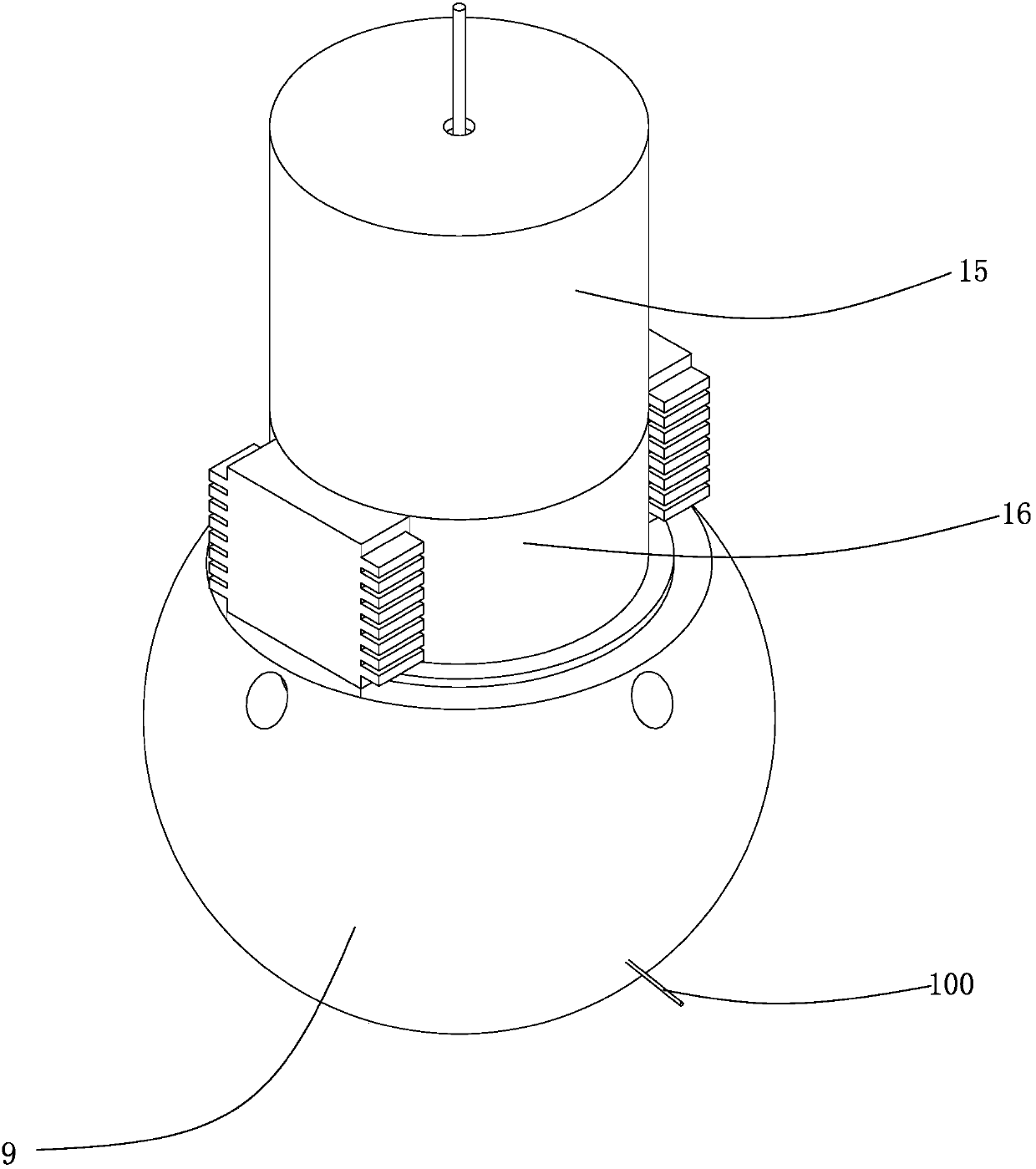

[0030] refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 8 As shown, a three-dimensional laser scanning head includes an optical path assembly and a drive assembly, and the drive assembly includes a vertical rotation motor 1, a horizontal rotation motor 2, a planetary gear transmission set 3, a horizontal rotation bracket mounting plate 4, a vertical rotation drive Gear 11, horizontal rotation drive gear 21, vertical rotation shaft 12, horizontal rotation bracket 22, vertical rotation driving bevel gear 13 and vertical rotation driven bevel gear 14, the planetary gear transmission set includes a vertical rotation planetary gear ring 33. Vertically rotating sun gear 31, vertically rotating planetary gear 32, vertically rotating planetary gear baffle plate 34, common gear carrier 35, horizontally rotating planetary gear ring gear 38, horizontally rotating planetary gear 37, horizontally rotating sun gear 36 And horizontal rotation planetary gear baffle plate 3...

Embodiment 2

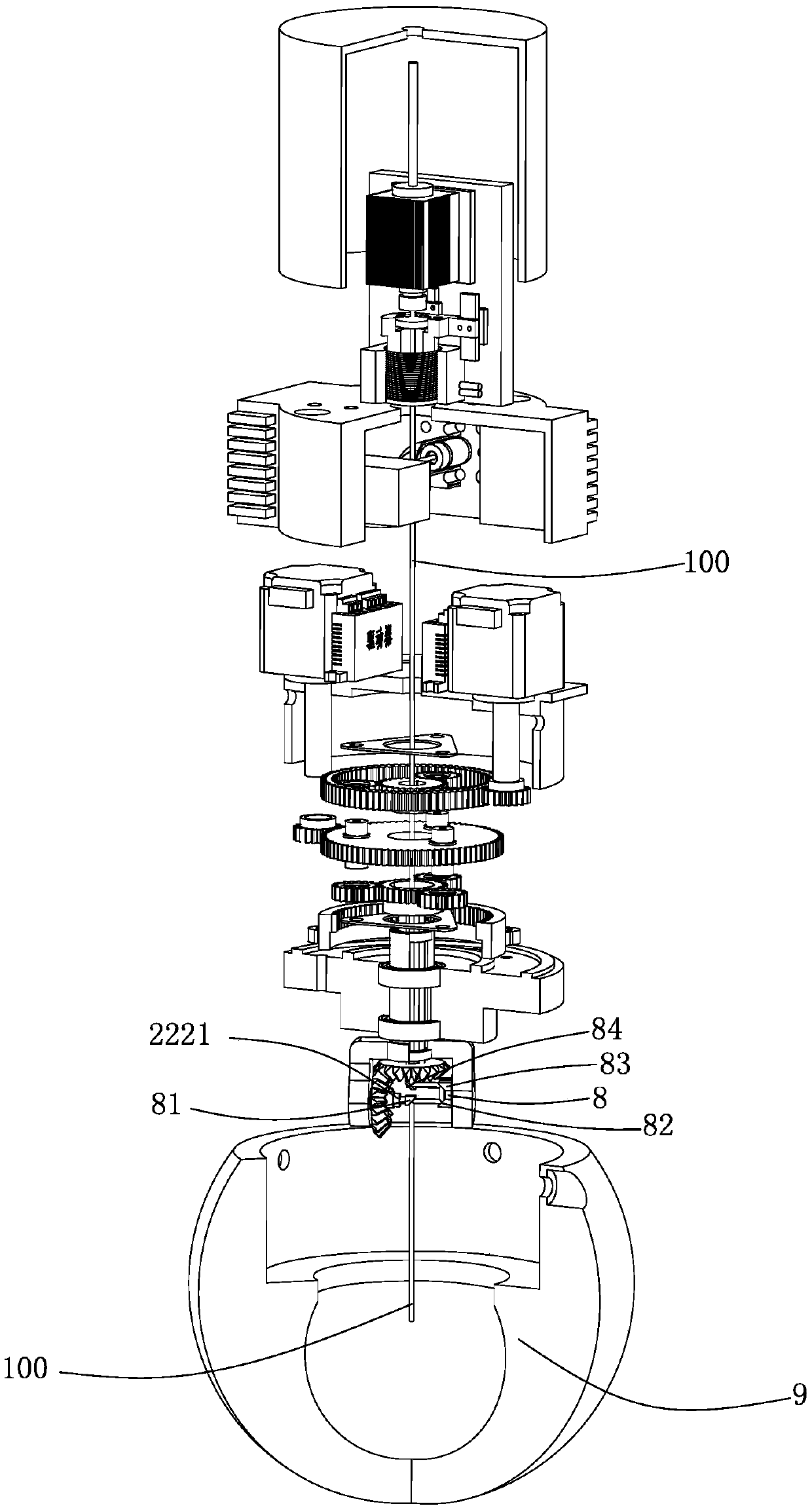

[0046] refer to Figure 5 , Figure 6 , Figure 7 , Figure 8 and Figure 9As shown, a three-dimensional laser scanning head includes an optical path assembly and a drive assembly, and the drive assembly includes a vertical rotation motor 1, a horizontal rotation motor 2, a planetary gear transmission set 3, a horizontal rotation bracket mounting plate 4, a vertical rotation drive Gear 11, horizontal rotation drive gear 21, vertical rotation shaft 12, horizontal rotation bracket 22, vertical rotation driving bevel gear 13 and vertical rotation driven bevel gear 14, the planetary gear transmission set includes a vertical rotation planetary gear ring 33. Vertically rotating sun gear 31, vertically rotating planetary gear 32, vertically rotating planetary gear baffle plate 34, common gear carrier 35, horizontally rotating planetary gear ring gear 38, horizontally rotating planetary gear 37, horizontally rotating sun gear 36 And horizontal rotation planetary gear baffle plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com