Three-dimensional technology based factory design method

A factory design and technology technology, applied in the field of factory design based on three-dimensional technology, can solve hidden problems that are difficult to find, omissions and collisions, complex structures, etc., to improve cost control capabilities, achieve information symmetry, and improve design quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

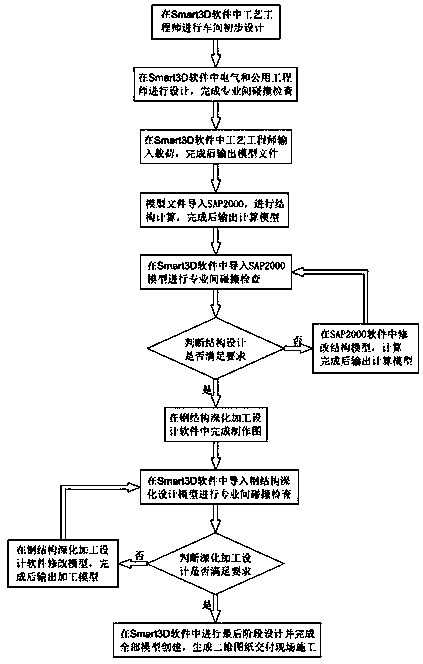

[0029] see figure 1 , a plant design method for a 3D model of a raw material batching station in a cement plant. The 3D model is divided into four parts: process, electrical, common and structural. The process, electrical and common parts are all created in Smart3D software; The structural design calculation is completed in the SAP2000 software, and the steel structure processing drawings are completed in the detailed design software. The specific steps are as follows:

[0030] Step 1: Run the Smart3D software, set the logical structure of the factory and define the color of the model, and start the 3D preliminary design. Firstly, the process model design is carried out, and the process engineer completes the preliminary creation of the workshop process 3D model in the order of: column-beam-floor-equipment-stairs-wall-door-non-standard pipe-railing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com