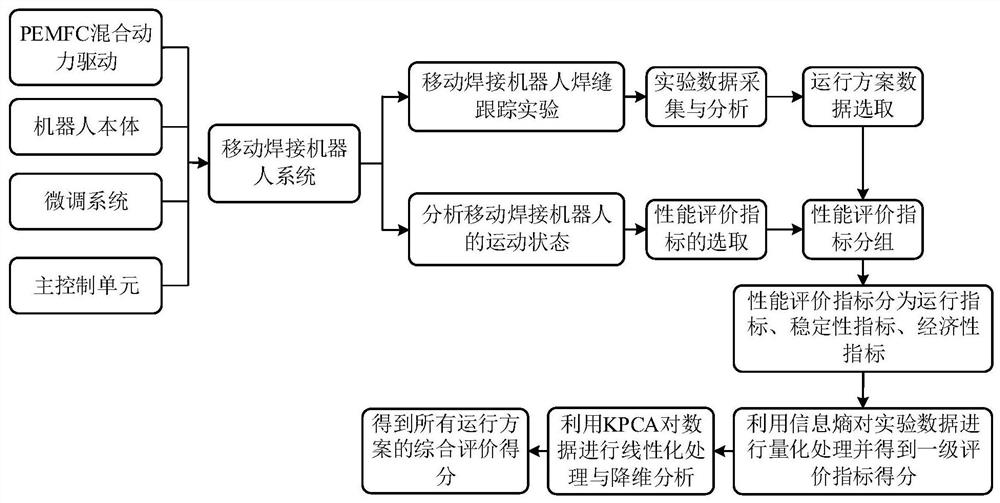

A comprehensive evaluation method for the operation scheme of mobile welding robot

A technology for welding robots and operation schemes, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of less research on robot system performance evaluation, achieve reliability and practicability, and improve continuous power supply time, the effect of improving sports performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

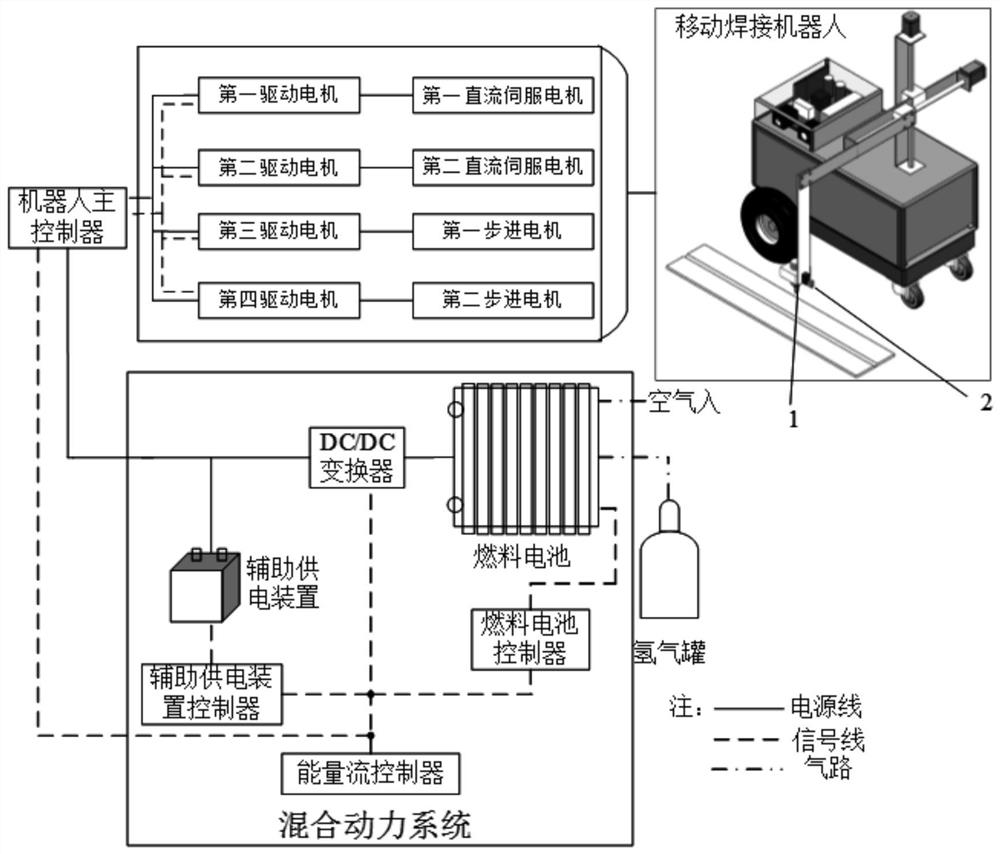

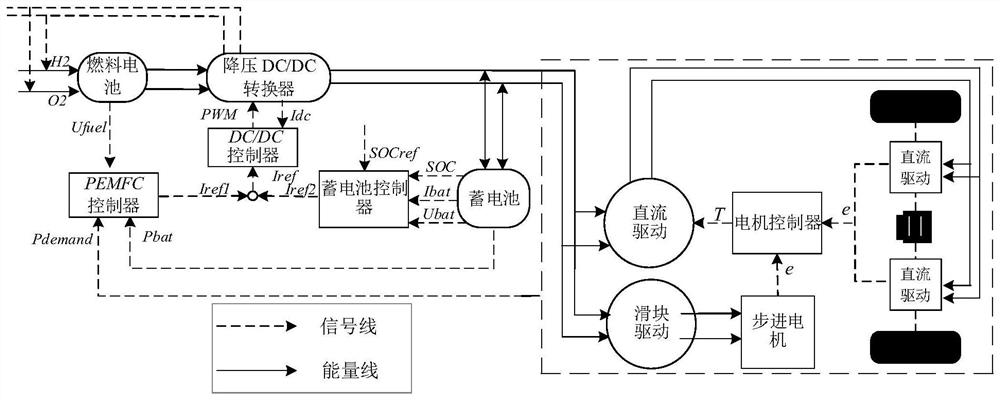

[0043] Such as figure 2 As shown, the welding robot system in this evaluation method includes a mobile welding robot body, a robot main controller and a fuel cell hybrid power system. The fuel cell hybrid power system is connected to the welding robot body through a drive controller. Among them, the hybrid power system includes a main power supply, an auxiliary power supply device and an energy management unit. The main power supply is a fuel cell, and the auxiliary power supply device is a battery. The output end of the fuel cell is connected to the drive controller through a Buck DC / DC converter, and the battery is connected in parallel to The output end of the Buck type DC / DC converter and the energy management unit are respectively connected to the mobile welding robot, the fuel cell, the storage battery and the Buck type DC / DC converter.

[0044] The welding robot controls the output current through a Buck DC / DC converter, and the energy management control process includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com