Automatic punching machine used for building boards

An automatic punching and building board technology, applied in the field of mechanical processing, can solve the problems of hole position deviation, waste of labor, time, affecting installation operations, etc., and achieve the effect of reducing output, saving time, and reducing labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

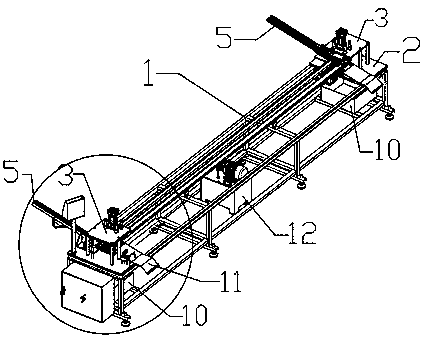

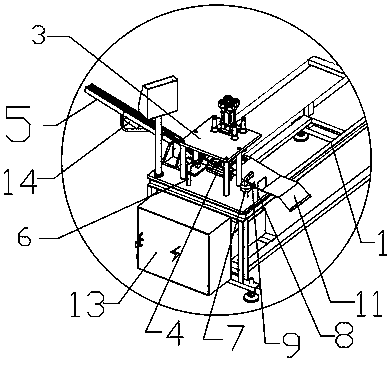

[0025] Such as figure 1 and figure 2 Shown, embodiment 1 of the present invention is:

[0026] An automatic punching machine for building panels, comprising a frame 1, a hydraulic station 12 located under the frame 1, a workbench 2 is symmetrically arranged at both ends of the frame 1, and a punching device 3 located on the workbench 2 And the plate positioning seat 4 below the stamping device 3, also includes a discharge assembly 5 for carrying plates, a push assembly 6, a material retaining assembly 7 and a blanking pallet 11, the discharge assembly 5 and the blank The pallets 11 are respectively located on both sides of the plate positioning seat 4, the pushing assembly 6 is located on one side of the discharging assembly 5, and the blocking assembly 7 is located on the plate positioning seat 4 close to the blanking pallet 11 side; also be provided with electrical box 13 on the side of stamping device 3.

[0027] Preferably, the discharge assembly 5 includes a discharge...

Embodiment 2

[0030] Embodiment 2, in order to reduce the noise generated by the sliding of the plates on the discharge plate, rubber pads are added on the discharge plate and the guard plate, and a muffler can also be installed on the inside of the guard plate.

Embodiment 3

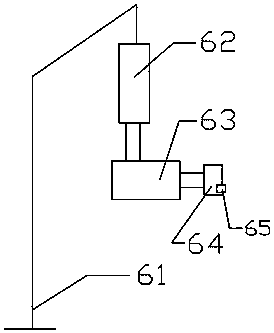

[0031] Embodiment 3, preferably, the pusher assembly 6 includes a pusher bracket 61, a pusher lifting cylinder 62, a pusher horizontal cylinder 63 and a pusher block 64; the lower end of the pusher bracket 61 is connected to the pusher lift The fixed end of the cylinder 62, the telescopic end of the pusher lifting cylinder 62 is vertically connected with the fixed end of the pusher horizontal cylinder 63, and the working end of the pusher horizontal cylinder 63 is detachably connected with the pusher block 64 A pressure sensor 65 is arranged inside the side of the pushing block 64 facing the plate positioning seat 4 .

[0032] Further, when the plate slides down to the bottom of the discharge plate, the position sensor detects the position signal of the plate, which makes the pushing lifting cylinder 62 work, makes the corresponding telescopic rod stretch, and makes the pushing block 64 drop to the height of the plate , then the pusher horizontal cylinder 63 works, and the pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com