Driving and control integrated system of robot joints

A technology of robot joint and drive control, applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., can solve the problems of unable to directly provide absolute spatial pose, unable to detect joint temperature state, etc., to achieve the effect of rapid exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

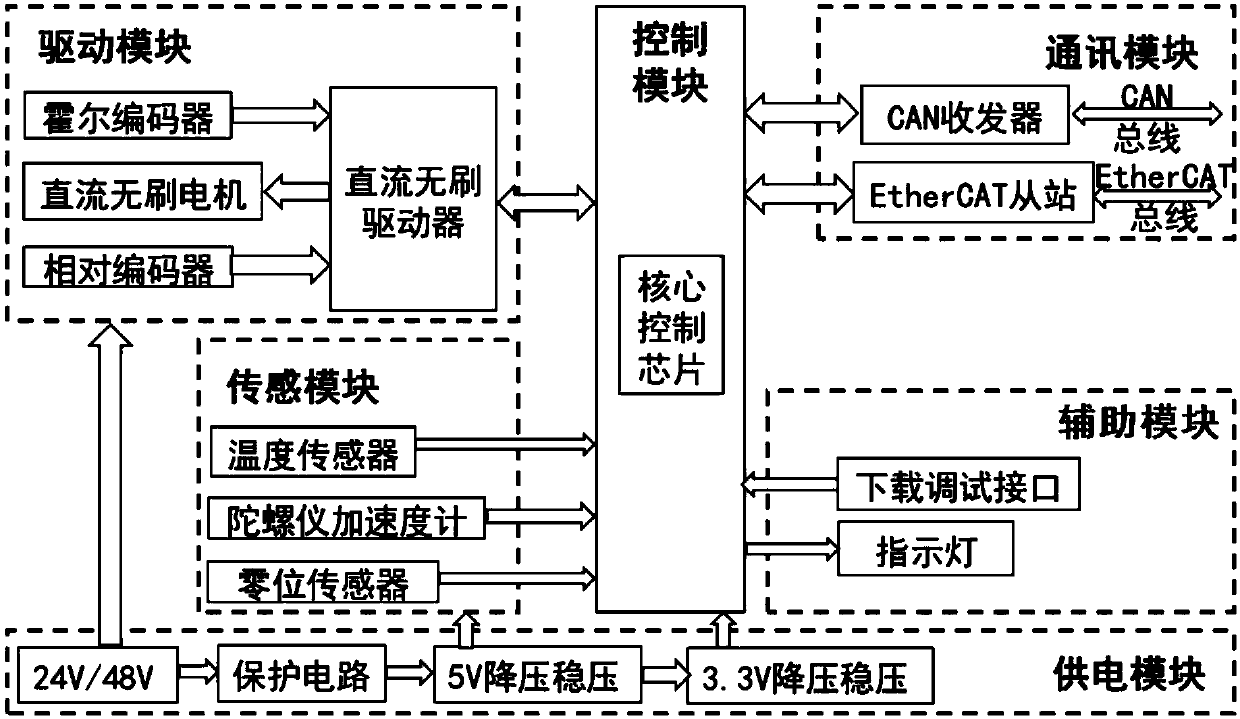

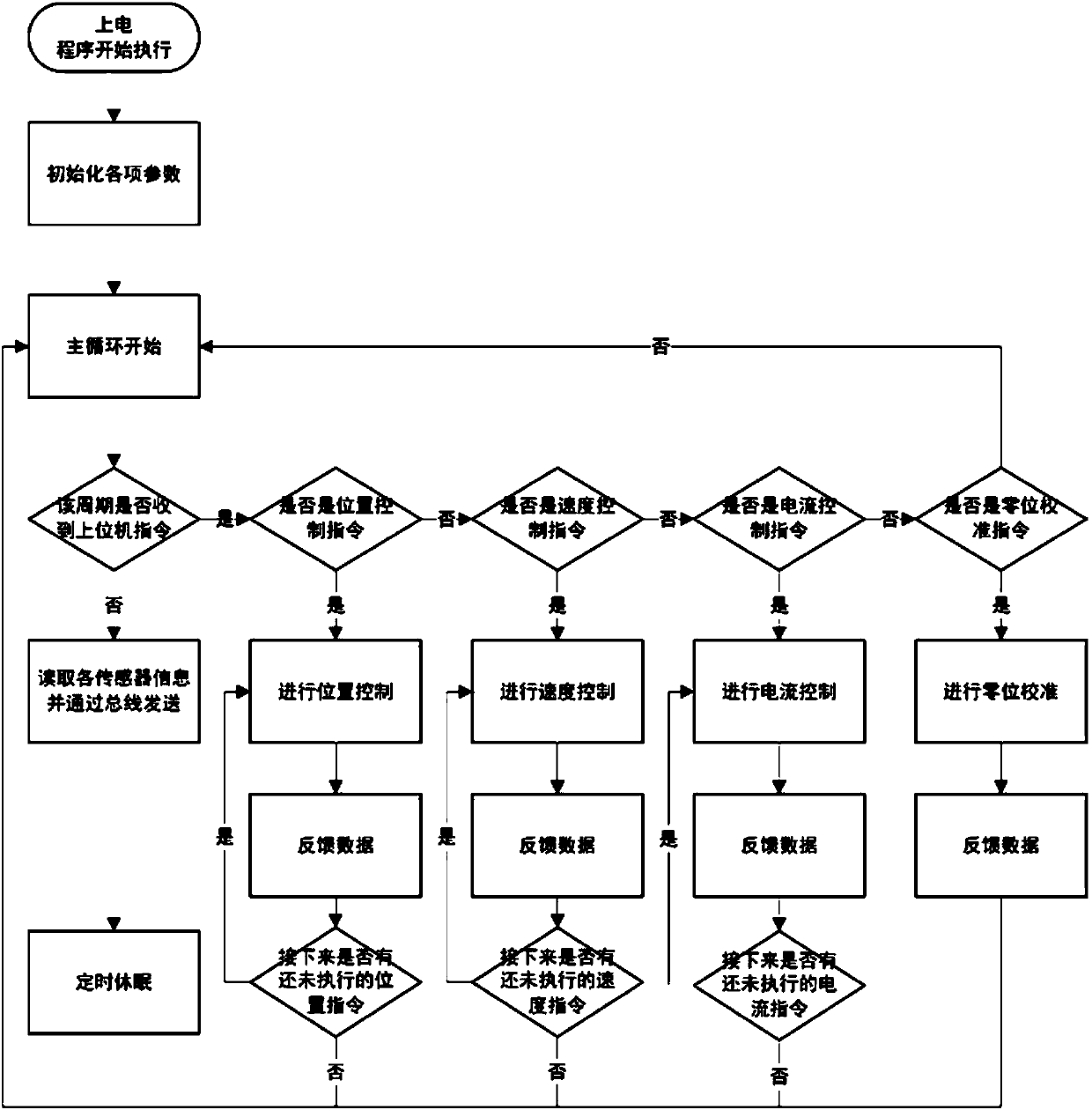

[0016] Such as figure 1 As shown, it is an integrated system for driving and controlling robot joints involved in this embodiment, including: a control module, a driving module, a sensing module and a communication module, wherein: the control module communicates with the driving module through an analog interface and a digital interface Connected, output the motion control command of the motor of the robot joint to the drive module, receive the motor current signal from the drive module, the encoder pulse information and obtain the current speed and acceleration signal of the motor; the sensor module collects the sensor data in the robot joint and feeds back to the control module; the communication module uploads the sensor data, motion control commands and motor motion status data to the host computer through the bus, and downloads the control commands sent from the host computer to the robot joint control module from the bus. From the communication control mode, the exchang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com