Non-triangular knitting machine and weaving method thereof

A knitting machine and triangular technology, applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of needle control complexity, weaving speed cannot be further improved, and is not easy to change, so as to achieve speed-up space, simple structure, and simple action Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The camless knitting machine provided in this embodiment mainly includes a mechanical part and a control part.

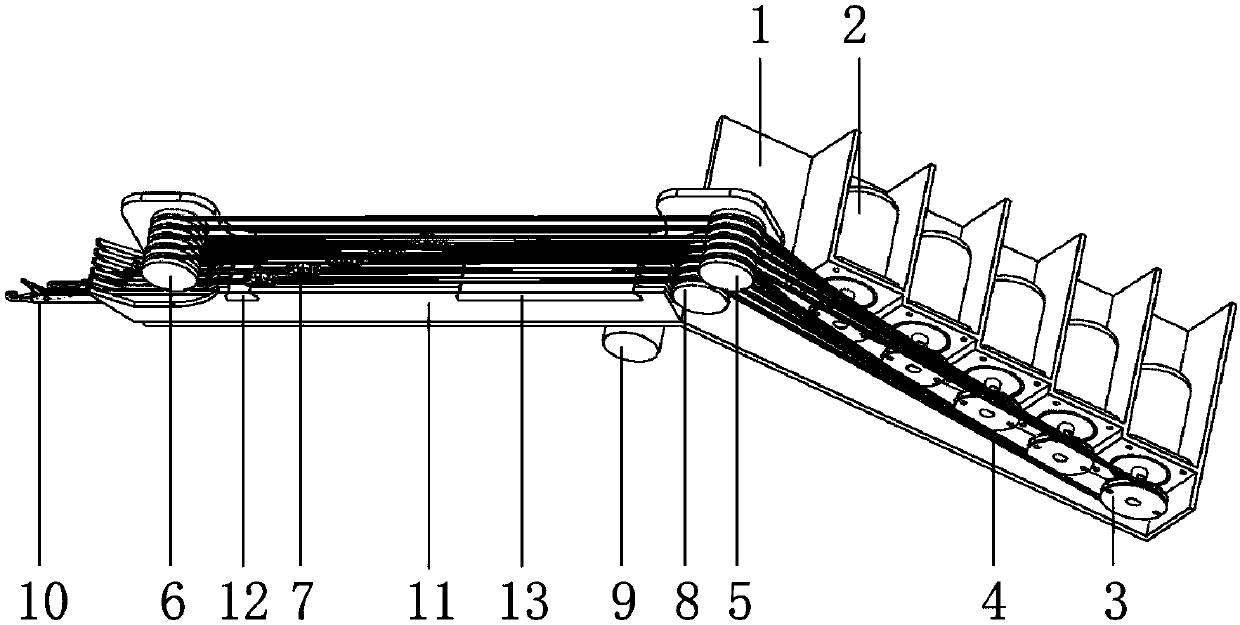

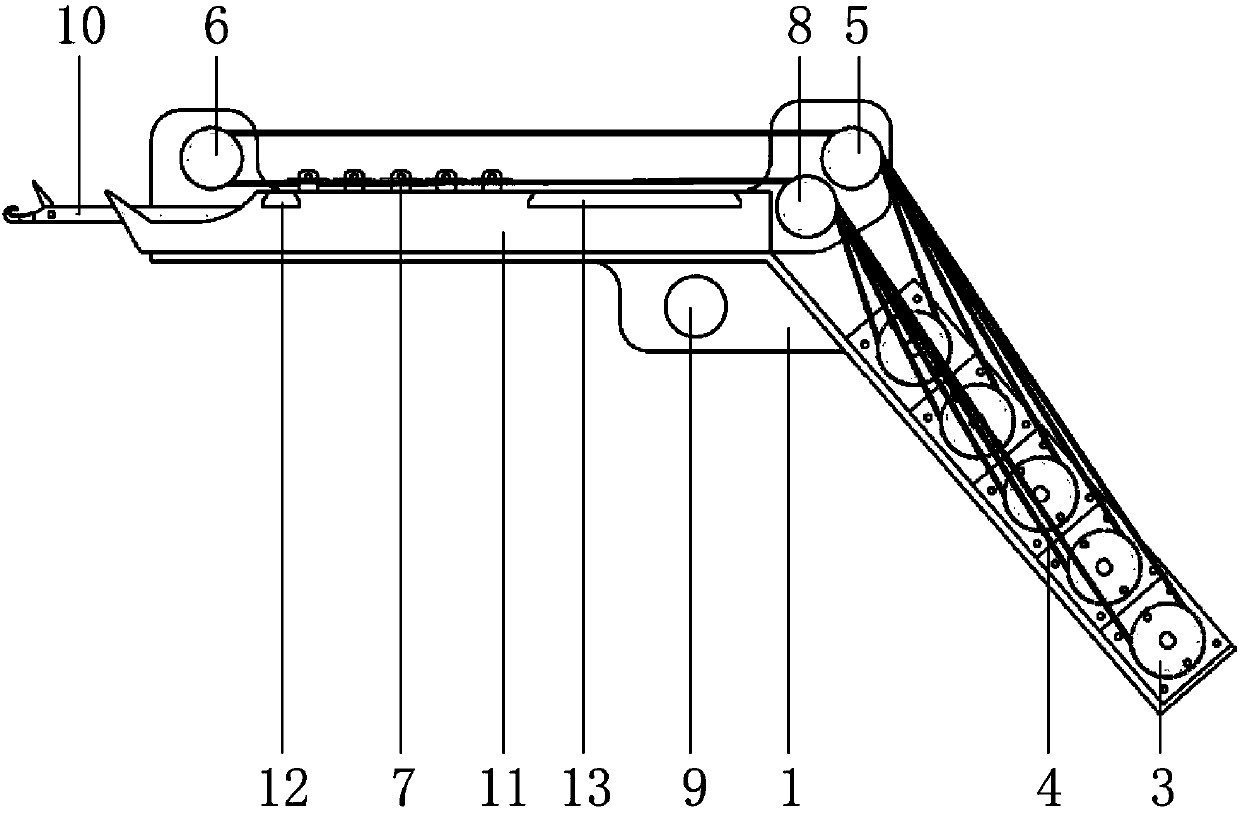

[0037] The mechanical part is mainly as attached figure 2 , 3 As shown, a camless knitting machine includes a needle plate base 1, which is in the shape of a broken line and installed on the frame of the loom. The position of the needle plate base 1 is controlled by the transverse guide rail and the needle plate traverse screw Constraints: The front end of the needle plate base 1 is equipped with needle plates 11 according to the traditional configuration method. Due to the large number of knitting needles 10 within the width range, the rear end of the needle plate base 1 presents a fan-shaped configuration in sequence. The rear end of the needle plate base 1 is provided with a plurality of trapezoidal grids, and a servo motor 2 is installed in the trapezoidal grids. The servo motor 2 drives the micro-elastic high-strength filament 4 through the pulley 3, a...

Embodiment 2

[0045] What this embodiment provides is a knitting method without a cam knitting machine, which specifically includes the following steps:

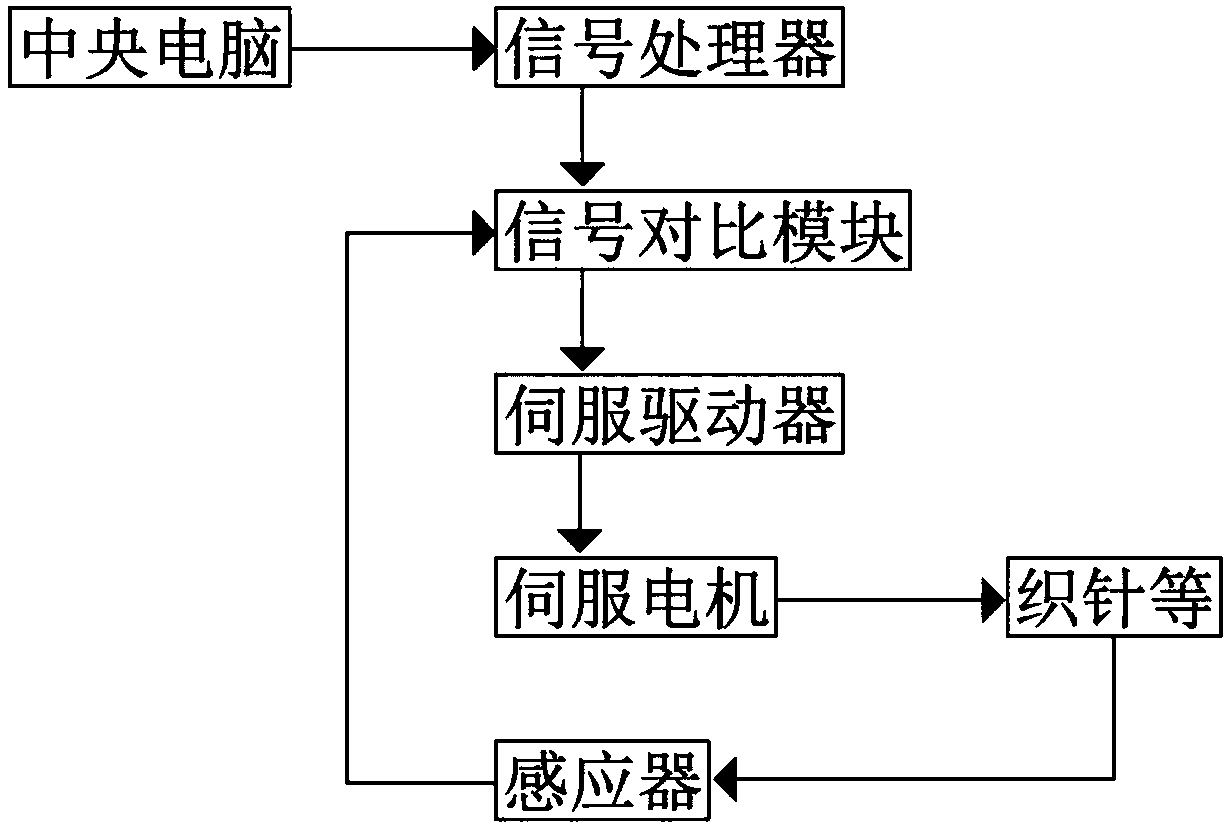

[0046] According to the specific conditions of the loom and the knitting needles, set the positions of the knitting needles, including setting the specific positions of the knitting needles when forming loops, tucking, transferring loops and not knitting; input the structure parameters of garment pieces into the central computer; The central computer analyzes and distributes the knitting actions of each row in sequence; the knitting actions of each row are processed by the signal processor and sent to the signal comparison module, and the signal comparison module sends the signal to the servo drive, and the servo drive outputs in pulse form sequentially For the servo motors, each servo motor completes the above distribution actions in sequence with a certain time difference after receiving the signal, and controls the corresponding knittin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com