Special-shaped column supporting system and construction method

A construction method and special-shaped column technology, which is applied in the processing of building materials, formwork/formwork/working frame, and on-site preparation of building components, which can solve the problems of high manufacturing and transportation costs, slow project progress, and inconvenient installation. problems, to achieve the effect of saving materials and labor, high production costs, and convenient support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

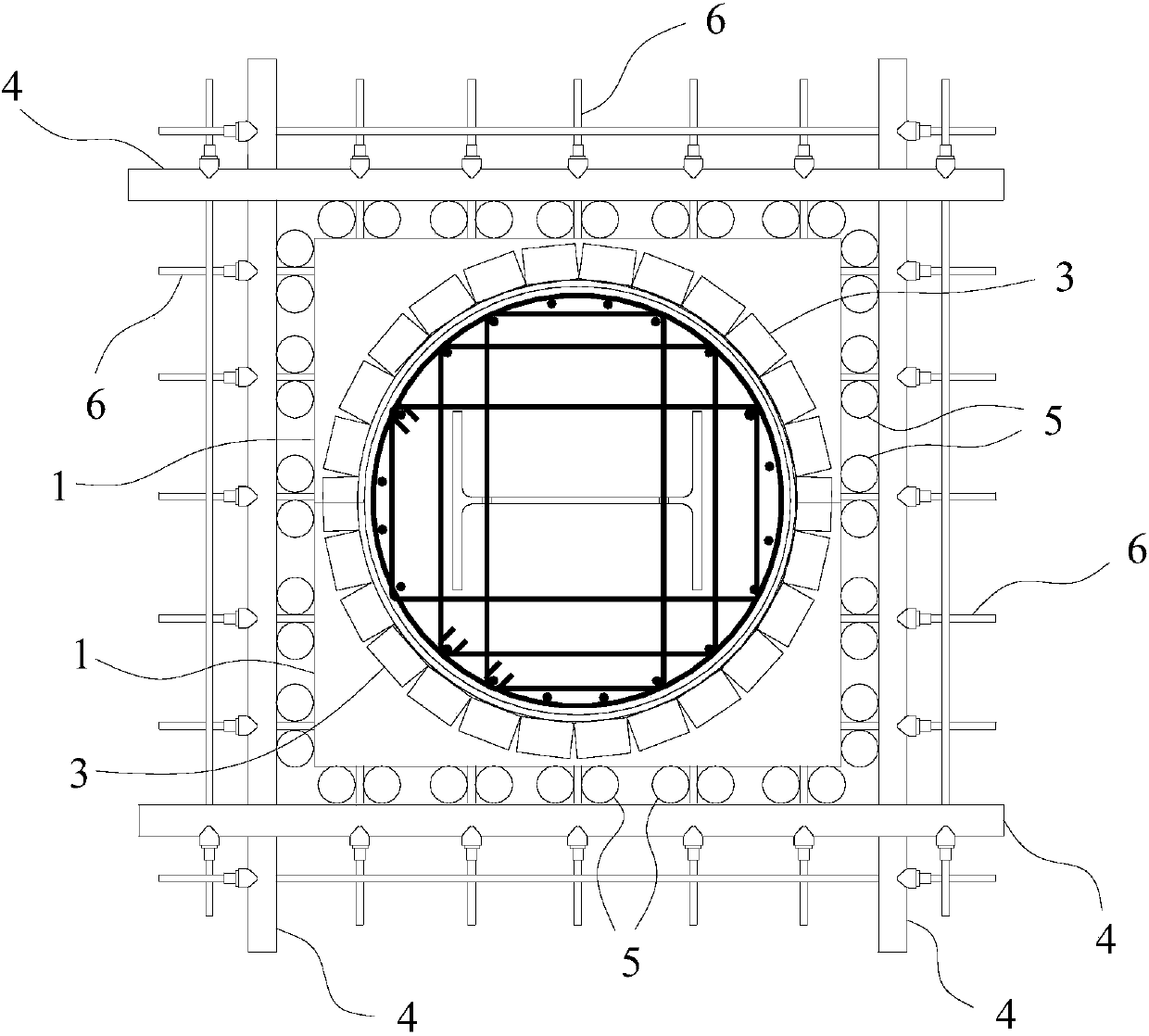

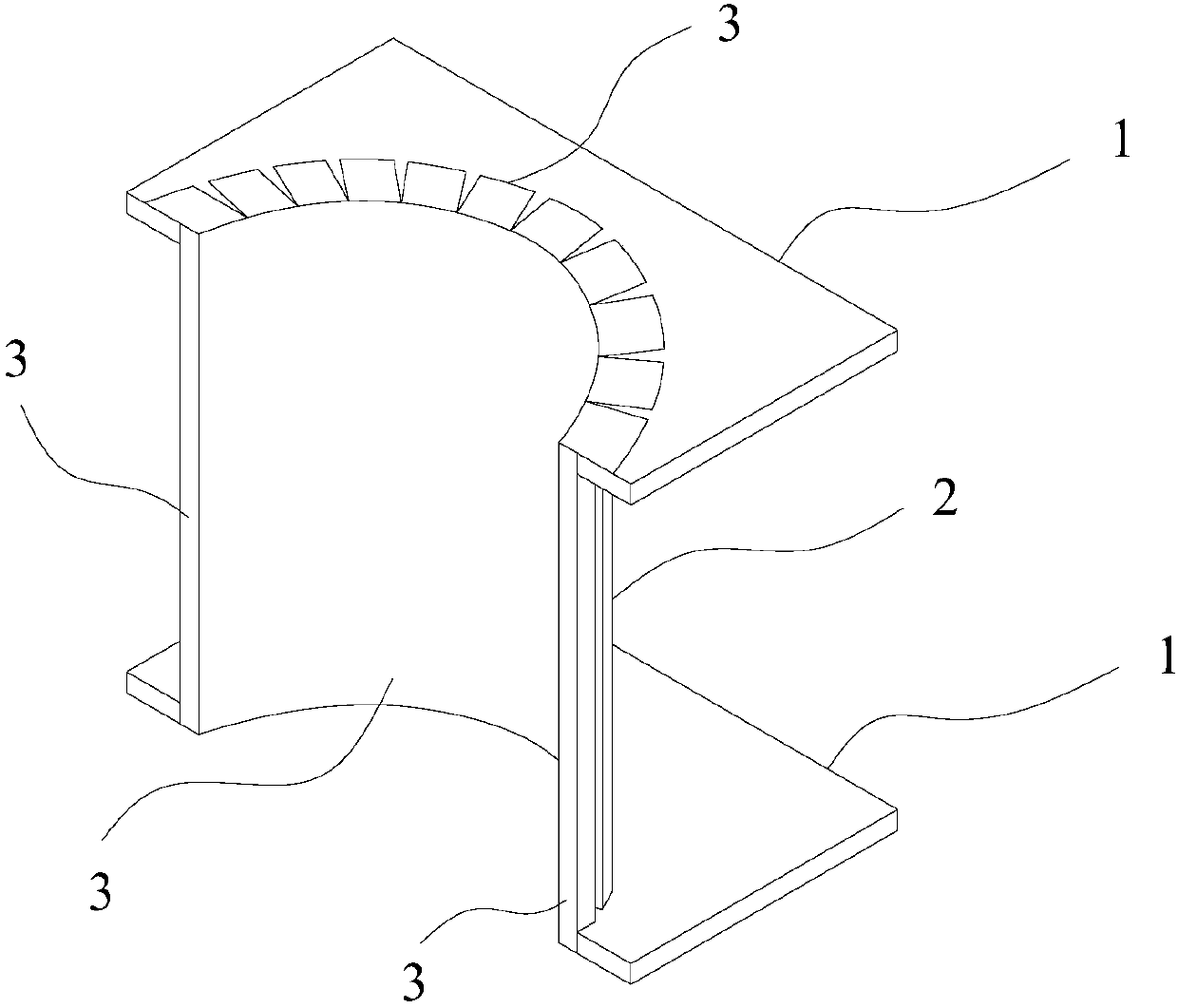

[0048] like Figure 1-5 As shown, a support system for special-shaped columns includes enclosure members and support members, the enclosure members enclose a closed area suitable for the shape of the column to be poured, and the support members are arranged on the outside of the enclosure members And be used for supporting described enclosure member, described enclosure member comprises two arc formworks, and each described arc formwork comprises two shaping boards 1, several connecting parts 2 and panels 3, and several connecting parts 2 connect Between the two shaped plates 1, the section of the special-shaped column to be poured is circular, the inner surface of the two shaped plates 1 is a semicircular arc, and all the connecting parts 2 are connected along the semicircular arc , closely arranged, with a spacing equal to 5cm, the inner wall of the cavity formed by the inner surfaces of all the shaped plates 1 and the inner surfaces of all the connecting parts 2 is adapted ...

Embodiment 2

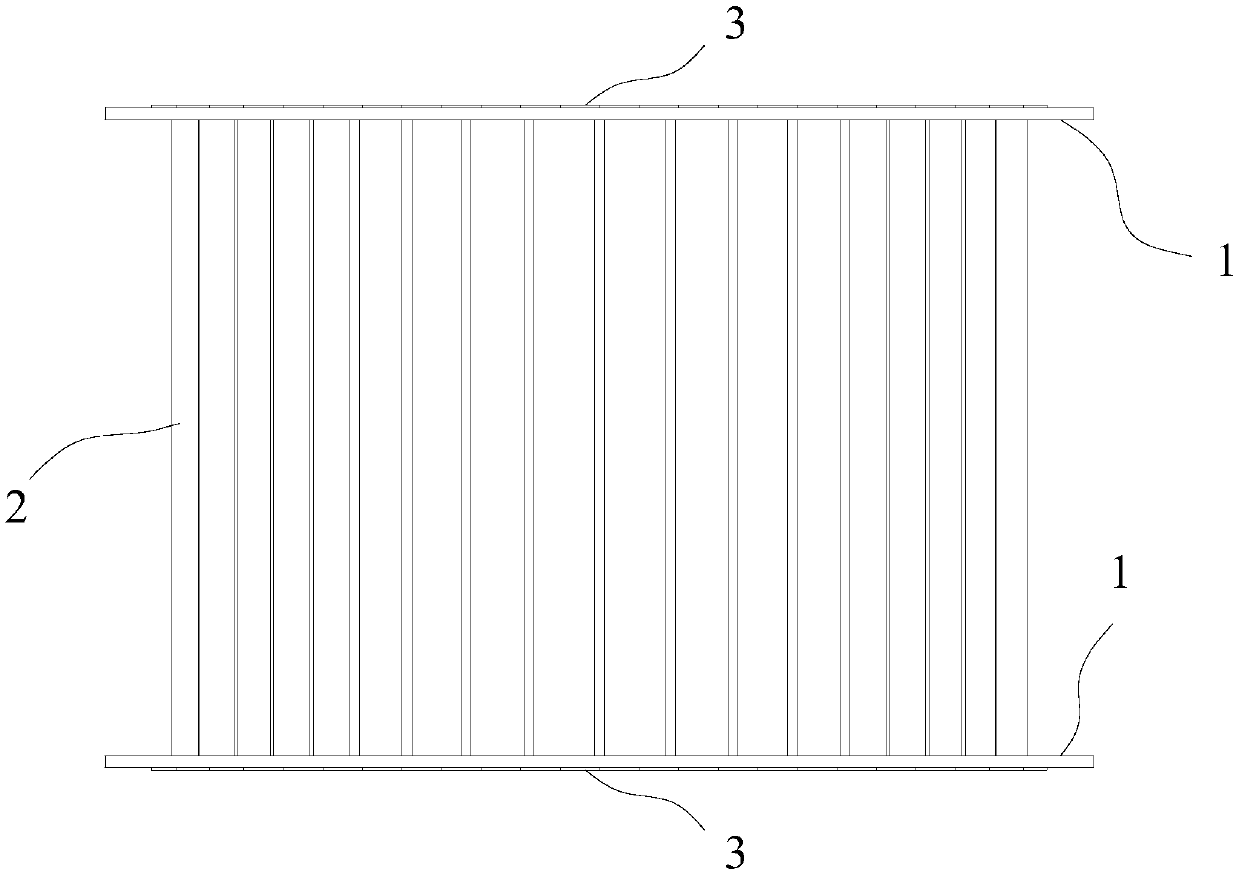

[0050] like Figure 6 As shown, the support system of a special-shaped column of the present invention has the same structure as that of Embodiment 1, and the difference from Embodiment 1 is that each of the arc-shaped templates includes three shaped plates 1, The distance between the shaped plates 1 at the upper and lower ends is relatively large, and when the strength of the formwork cannot be satisfied, a piece of the shaped plate 1 is added between the two shaped plates 1, and between two adjacent shaped plates 1 A layer of connecting parts 2 is connected to improve the strength of the formwork, save materials, reduce splicing times, and help prevent grout leakage.

Embodiment 3

[0052] like Figure 7 As shown, the support system of a special-shaped column of the present invention has roughly the same structure as that of Example 1. The difference from Example 1 is that the section of the special-shaped column to be poured is a combination of a circle and a rectangle, and the rectangular part is made of Three common templates 7 are used to support the mold, and the circular part is supported by two arc-shaped templates. The inner surface of each said shaped plate 1 is smaller than a semicircular arc, and the aluminum iron sheet is used to interact with the common template 7 at the joint Overlapping, the outermost section of the curved formwork is formed into a rectangle after the splicing is completed, and the support member is built on the outside of the curved formwork and the ordinary formwork 7, and the ordinary formwork 7 is a film-coated board.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com