Balance control method and balance control device of pulverized coal distributor

A technology of balanced control and distributor, applied in the combustion method, controlling combustion, adjusting fuel supply, etc., can solve the problems of small wind speed, stuck, blocked pipes, etc., and achieve the effect of long wind path and reliable sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below in conjunction with the accompanying drawings.

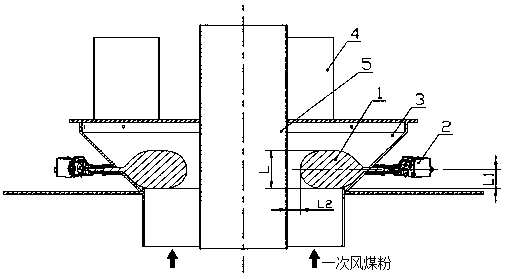

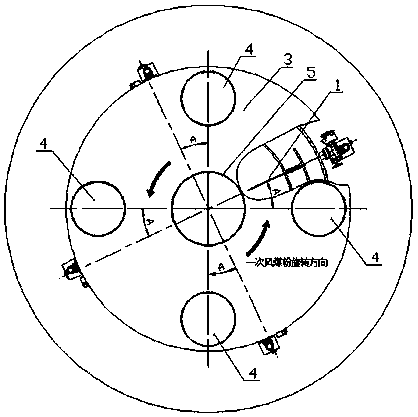

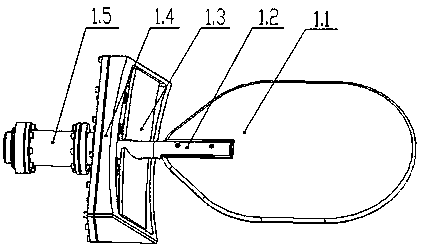

[0047] to combine figure 1 , figure 2 As shown, a pulverized coal distributor balance control device of the present invention is arranged on the pulverized coal distributor 3, and the upper end of the pulverized coal distributor 3 includes 4 primary air pulverized coal outlet pipes 4 (the number of primary air pulverized coal outlet pipes can be adjusted according to needs), the center is equipped with a coal drop pipe 5, and the pulverized coal distributor 3 is also equipped with four paddle valves 1 and an electric actuator 2 connected with the paddle valves, wherein the four paddle valves 1 are fixed and even Distributed on the side wall of the pulverized coal distributor 3, located below the primary air pulverized coal outlet pipe 4 and adjacent to the pulverized coal inlet port of the pulverized coal distributor 3, the center line of the paddle valve 1 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com